What Are the Advantages of Replaceable Inserts

If you’ve spent any time on a shop floor, you know the most expensive sound in the world isn’t the crash of a tool breaking—it’s the silence of a spindle that isn’t turning.

In high-production manufacturing, uptime is everything. Yet, I still see shops relying heavily on solid tooling for applications where they should have graduated to indexable solutions years ago. While solid carbide has its place (especially in micro-machining), relying on it for everything is a surefire way to inflate your operational costs.

The industry standard for efficiency is the replaceable insert (often called an indexable insert). These engineered tips don’t just cut metal; they cut the hidden costs of inventory, downtime, and setup.

Replaceable inserts are separate cutting tips, usually made of sintered carbide, that clamp onto a permanent tool body. Their primary advantages are lower cost per cutting edge, reduced machine downtime (due to rapid indexing), and versatility, allowing operators to change grades or geometries without removing the tool holder from the machine.

The Mathematics of “Cost Per Edge”

The biggest mistake I see procurement teams make is looking at the price of the tool rather than the price of the cut.

When you buy a solid carbide end mill or drill, you pay for the entire cylinder of expensive tungsten carbide, even though you only use the bottom few millimeters to cut. When that edge wears out, you have to send it out for regrinding or scrap the whole thing. This is a key distinction when evaluating solid vs. indexable drills and tooling.

With replaceable inserts, the math changes entirely. You aren’t paying for the shank (which is reusable steel); you are only paying for the cutting edge.

Here is the “Cost Per Edge” formula you should be using:

- Solid Tool: $80 tool / 1 usable life = **$80.00 per setup** (plus regrinding logistics).

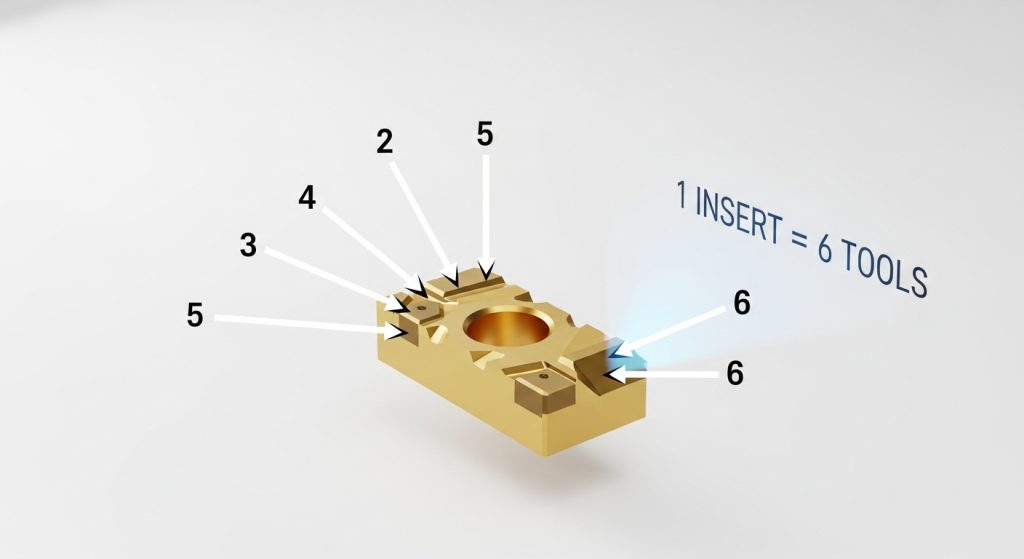

- Replaceable Insert: $12 insert with 6 cutting corners = **$2.00 per edge.**

In high-volume turning, milling, or indexable drilling, this difference isn’t just pennies; it’s a massive margin recovery. By utilizing multi-sided inserts (like WNMG or CNMG shapes), you are effectively buying six or more tools for the price of one small carbide wafer.

Slashing Downtime and Rapid Changeovers

In my experience running CNC lathes, the “touch-off” process is where productivity goes to die.

When a solid tool wears out, the operator has to:

- Stop the machine.

- Remove the entire tool holder.

- Install a new tool.

- Re-measure the offsets (X and Z axes) because the new tool length is never exactly the same as the old one.

Replaceable inserts eliminate this headache. Because the tool holder stays rigid in the turret, “indexing” the tool (rotating the insert to a fresh edge) takes less than 60 seconds.

Because modern inserts are manufactured to tight ISO tolerances, the cutting point remains in the exact same position. You generally don’t need to re-touch off the tool. You loosen the screw, rotate the insert, tighten it, and hit the green button.

Unmatched Versatility in Grade and Geometry

One of the frustrations with brazed or solid tools is that you are stuck with the geometry grind the manufacturer gave you.

Replaceable inserts give you a “Swiss Army Knife” capability. Let’s say you are turning 304 Stainless Steel in the morning, but a rush job comes in for 6061 Aluminum in the afternoon.

You don’t need to strip your turret. You keep the same tool holders installed but simply swap the insert:

- For Stainless: Use a tough PVD-coated grade with a chip breaker designed to handle heat.

- For Aluminum: Swap to a polished, uncoated insert with a high-rake geometry to prevent welding.

You can also adjust your chip breaker geometry without changing the tool. If you’re struggling to break chips on a finishing pass, you can switch from a standard insert to a “wiper” geometry or a finishing-specific breaker. That level of adaptability just doesn’t exist with solid tooling.

Eliminating Thermal Stress (The Metallurgical Advantage)

This is a point often overlooked by generalists, but it’s critical for metallurgists and engineers.

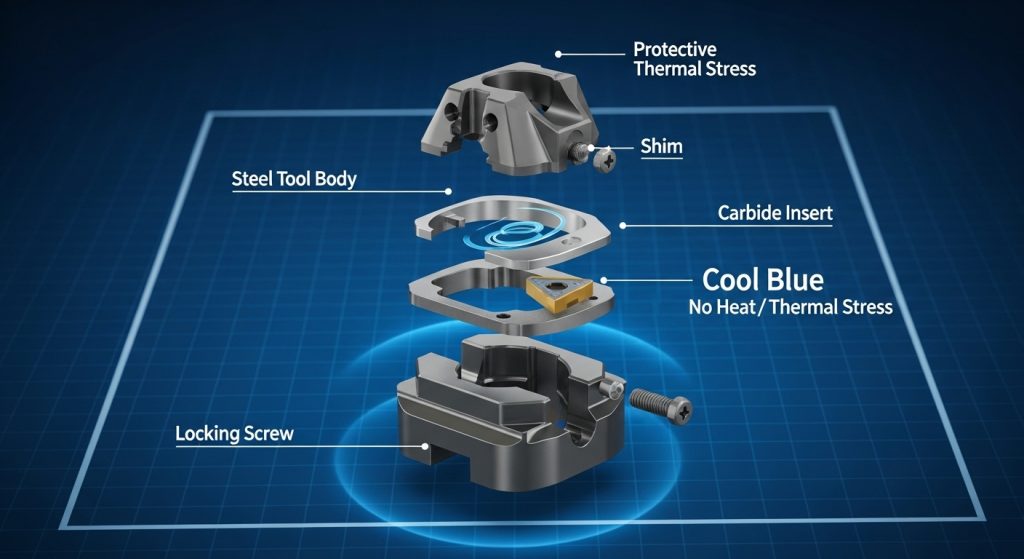

Brazed carbide tools are created by joining a carbide tip to a steel shank using heat. The problem? Steel and carbide expand and contract at different rates. When the tool cools down after brazing, it locks in residual thermal stress.

When you put that brazed tool into a heavy cut, the heat from machining adds to that stress, often leading to micro-cracking or premature failure, especially in interrupted cuts (like turning a square shaft or milling gear teeth).

Replaceable inserts are mechanically clamped. There is no heat involved in attaching them to the holder. This means the carbide is stress-free and can handle the thermal shock of coolant much better than a brazed equivalent.

Consistency and “Factory Fresh” Performance

There’s a dirty secret about regrinding solid tools: they are never quite the same as the first time you used them.

When you regrind a tool, you alter its diameter and geometry slightly. Furthermore, unless you pay a premium for re-coating, you’ve lost that specialized TiAlN or AlTiN coating that gave the tool its heat resistance.

With replaceable inserts, every time you index to a new edge, you are getting factory-fresh performance. The coating, the edge preparation (honing), and the micro-geometry are identical to the first cut. This consistency is vital for automated “lights-out” manufacturing where you need predictable tool life to improve productivity.

Comparison: Replaceable Inserts vs. Solid Carbide

Here is the bottom line on when to use which technology.

| Feature | Replaceable Inserts | Solid Carbide / Brazed |

| Cost Efficiency | High (Low cost per edge) | Low (High initial cost) |

| Setup Time | Fast (Index in machine) | Slow (Requires offsets) |

| Diameter Range | Best for >10mm | Best for <10mm |

| Surface Finish | Excellent | Superior (for micro-finishing) |

| Rigidity | High (Steel holder body) | Highest (Solid mass) |

Conclusion

Switching to replaceable inserts isn’t just about saving a few dollars on consumables; it’s about transforming your shop’s workflow. By adopting indexable tooling, you reduce machine downtime, minimize thermal failure risks, and gain the flexibility to tackle diverse materials with the same core setup.

While solid carbide will always reign supreme for micro-drilling and ultra-precision finishing, for the vast majority of general turning and milling applications, replaceable inserts are the clear ROI winner.

Ready to optimize your tooling strategy? Check out our complete indexable drilling guide and explore AccuCut’s range of high-performance indexable solutions to keep your spindles turning and your costs down.

Frequently Asked Questions

What is the difference between indexable and replaceable inserts?

In the industry, these terms are often used interchangeably. However, “indexable” specifically refers to inserts with multiple cutting edges that can be rotated (indexed). “Replaceable” is the broader term covering any tip (even single-edge drill tips) that can be swapped out without discarding the tool body.

Are replaceable inserts better than solid carbide?

They are better for cost and efficiency in medium-to-large diameter cuts (typically above 10mm). Solid carbide is generally “better” for very small diameters (under 3mm) or applications requiring extreme rigidity and surface finishes where a mechanical clamp might introduce slight vibration.

How many times can you index a turning insert?

It depends on the shape. A positive triangular insert (TCMT) might only have 3 edges. However, a double-sided negative insert like a WNMG (Trigon shape) offers 6 cutting edges, providing exceptional value. Always check the ANSI/ISO designation to determine the number of usable corners.

Can you regrind replaceable inserts?

Technically, yes, but it is rarely cost-effective. The value of an insert lies in its specific coating and pressed geometry (chip breakers). Regrinding removes the coating and alters the chip breaker, destroying the insert’s performance advantages. It is almost always more economical to recycle the carbide and use a fresh insert.

Why do replaceable inserts use screw clamps?

Screw clamps (or lever locks) provide a secure mechanical force that holds the insert rigidly against the pocket walls. This ensures repeatability. Unlike brazing, screws allow for rapid changing of the insert without removing the holder from the machine turret.