Which Drill Insert Is Best for Steel

There is a specific sound every machinist dreads: that high-pitched squeal halfway through a deep hole in a block of 4140 steel. It usually means your insert just failed, and if you don’t hit the feed hold button in the next half-second, you’re looking at a friction-welded drill body and a scrapped part.

At Accurate Cut, we analyze tool failure data daily, and the most common issue we see isn’t the machine or the program—it’s failing to choose the right drill insert grade.

Many shops treat “steel” as a single category, grabbing whatever generic carbide insert is in the drawer. But steel is a spectrum. The insert that shears beautifully through gummy 1018 low-carbon steel will burn up instantly in abrasive D2 tool steel.

If you want to stop changing inserts every 50 holes and start running lights-out production, you need to move beyond “general purpose” choices. Here is the engineering-level breakdown of which drill insert is best for steel, based on our shop floor data and ISO standards.

Decoding ISO P: The Baseline for Steel

Before we talk about specific coatings, we need to speak the language of the industry: ISO P. In the manufacturing world, the “Blue Group” (ISO P) covers everything from unalloyed low-carbon steel to high-tensile alloy steels.

However, the ISO designation alone isn’t enough. You need to look at the hardness scale, usually designated by numbers like P10, P25, or P40.

The Bottom Line on ISO Grades:

- P01 – P10 (Hard/Brittle): These are designed for high-speed finishing in stable conditions. They have high wear resistance but low impact strength. Use these for continuous cuts in hardened steels.

- P20 – P30 (The Universal Sweet Spot): If you are running a job shop and don’t know exactly what steel is coming next, a P25 grade is your safest bet. It balances hardness with enough toughness to handle minor vibrations.

- P40 – P50 (Soft/Tough): These grades are incredibly tough but wear faster. They are essential for interrupted cuts (like drilling through cross-holes) or unstable setups where vibration would crack a harder insert.

Accurate Cut Insight: We often see machinists blaming the coolant when the real culprit is using a P10 grade in a P40 application. If your setup lacks rigidity, high-hardness grades will chip immediately.

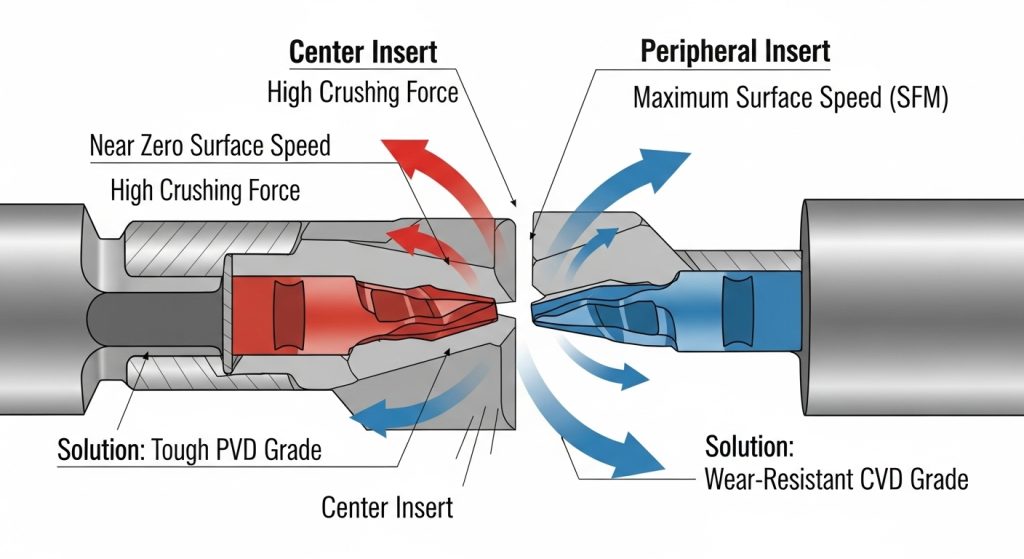

The “Inside-Out” Strategy: Peripheral vs. Central Inserts

Here is the secret that separates general machinists from tooling experts: The best insert for your drill might actually be two different inserts.

Indexable drills typically use two inserts: a Central (Inner) insert and a Peripheral (Outer) insert. Physics dictates that these two positions experience vastly different forces.

The Peripheral (Outer) Insert

This insert travels at the full Surface Feet Per Minute (SFM) of your program. It generates massive heat due to friction speed.

- The Challenge: Heat and abrasive wear.

- The Solution: You need a harder, heat-resistant grade (like P15 or P20) with a CVD coating.

The Central (Inner) Insert

As you get closer to the center of the drill, the surface speed drops. At the very center, the speed is effectively zero. This insert isn’t cutting so much as it is crushing and extruding the material.

- The Challenge: High shearing forces and shock.

- The Solution: You need a tough, impact-resistant grade (like P30 or P40) with a PVD coating.

Quick Answer: For optimal tool life in alloy steel, run a tough PVD grade in the center pocket and a wear-resistant CVD grade in the outer pocket.

Matching Geometry to Steel Type

“Steel” isn’t specific enough. The chip formation of 1018 is nothing like 4140. To optimize your process, you must match the insert geometry (chipbreaker) to the carbon content of the material.

Low Carbon Steel (1018, A36)

These steels are soft and “gummy.” They love to stick to the cutting edge, causing Built-Up Edge (BUE), which eventually rips the coating off the insert.

- Best Geometry: Sharp, positive rake angles.

- Best Grade: Uncoated or PVD TiN/TiCN (polished if possible).

- Why: You need a sharp edge to shear the material cleanly. A honed edge (common on heavy-duty inserts) will just push the material, causing tearing.

Alloy Steel (4140, 4340)

These materials generate significant heat and are more abrasive. Gummy sticking is less of an issue, but thermal cracking is a real threat.

- Best Geometry: Stronger negative T-lands (edge preparation).

- Best Grade: CVD Alumina (Al2O3) coated grades.

- Why: The negative land protects the edge from chipping under high load, while the Alumina coating acts as a heat shield, forcing the heat into the chip rather than the tool.

Tool Steel (D2, A2, H13)

When drilling tool steels in their annealed state, you are battling abrasion.

- Best Geometry: Reinforced edges.

- Best Grade: Sub-micron carbide substrates (P10-P15 range).

- Why: Standard grades will wear down rapidly (flank wear). You need the hardest substrate possible that won’t crack.

Coating Technologies: PVD vs. CVD

You’ll see these acronyms on every box of inserts. Consulting a drill insert coatings guide can explain the chemistry, but understanding the functional difference here can save you thousands in tooling costs.

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

| Thickness | Thin (2-5 microns) | Thick (5-15 microns) |

| Edge Quality | Sharp, clean edge | Rounded, honed edge |

| Best Attribute | Toughness & Adhesion | Heat & Wear Resistance |

| Best Application | Inner inserts, gummy steel, unstable setups | Outer inserts, high-speed alloy steel production |

Accurate Cut Tip: If you are running an older machine with a loose spindle or significant runout (>0.001″), stick to PVD grades. CVD coatings are like ceramic plates—hard but brittle. If your spindle wobbles, CVD inserts will micro-chip instantly.

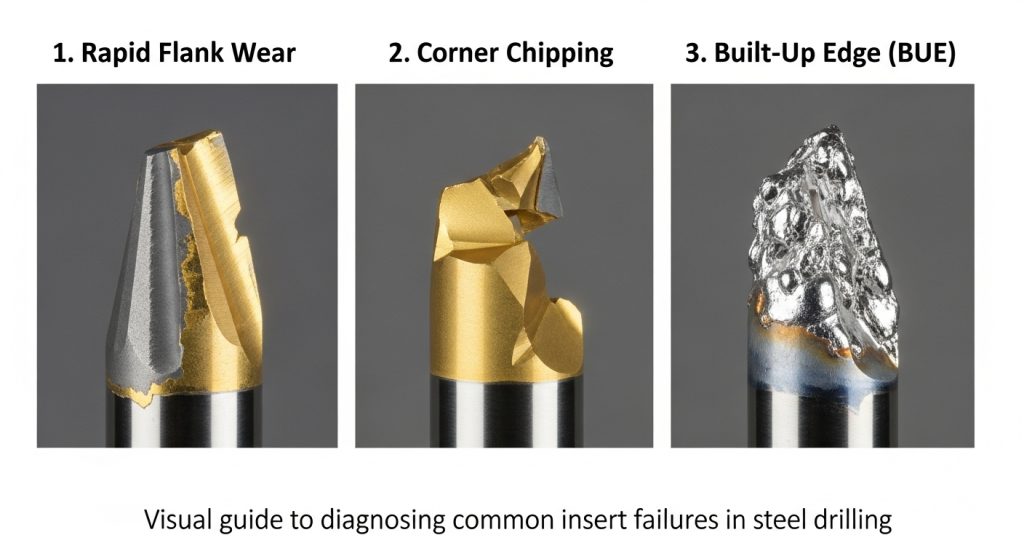

Troubleshooting Common Insert Failures

When an insert fails, it leaves clues. Don’t just toss it in the scrap bin—read the wear pattern to adjust your choice.

Rapid Flank Wear

The edge is wearing down smoothly but too fast.

- Diagnosis: The grade is too soft, or speed is too high.

- Fix: Switch to a harder grade (Move from P30 to P15) or a CVD coating.

Chipping on the Outer Corner

Chunks of the cutting edge are missing on the periphery.

- Diagnosis: Vibration or runout is hammering the brittle carbide.

- Fix: Use a tougher grade (Move from P15 to P30) or check your coolant pressure.

Built-Up Edge (BUE)

Material is welded onto the cutting edge.

- Diagnosis: Cutting speed is too low, or the edge isn’t sharp enough.

- Fix: Increase speed (SFM) or switch to a sharper PVD insert to slice through the gumminess.

FAQ: Drill Insert Selection

Can I use the same insert for Stainless Steel (ISO M) and Carbon Steel (ISO P)?

Technically, yes, but it’s not efficient. Stainless steel grades are designed to be very sharp to prevent work hardening. If you use them on standard steel, they may chip prematurely. If you use a dull steel grade on stainless, you will work-harden the material instantly. For high production, keep them separate.

When should I change a steel drill insert?

Don’t wait for the breakage noise. Monitor the spindle load meter. A 10-15% increase in load usually indicates the coating has worn through. Visually, look for flank wear exceeding 0.3mm (0.012″). Consistent tool life management is key to profitability.

Is a trigon or square insert better for drilling steel?

Square inserts (like SPMG) generally offer four cutting edges, making them more economical. However, Trigon (WCMX) inserts often provide better centering capabilities and stability in deeper holes (3xD and up) due to their geometry.

How does coolant pressure affect insert life in steel?

In drilling, coolant does two things: cools the edge and evacuates chips. In steel, chip evacuation is critical. If you don’t have high pressure (300+ PSI), chips can pack in the flutes. If you have low coolant pressure, use a tougher insert grade, as the heat cycles will be more severe.

What is the best insert for drilling AR400/AR500 plate?

AR (Abrasion Resistant) plate is nasty stuff. Forget standard steel grades. You need a high-hardness P10 or P15 grade, low RPM, and high feed to get under the hard skin. Do not dwell; if the drill rubs, it will work-harden the spot and destroy the insert.

Conclusion

Choosing the best drill insert for steel isn’t about finding the most expensive gold-coated carbide in the catalog. It’s about matching the physics of your specific operation—machine rigidity, steel hardness, and cutting mechanics—to the right tool.

Key Takeaways:

- Start with P25: It’s the industry standard balance of tough and hard.

- Mix Your Grades: Use tough PVD in the center and wear-resistant CVD on the outside for optimal results.

- Respect the Material: Gummy steels need sharp edges; hard alloys need heat protection.

If you are seeing inconsistent tool life or catastrophic failures in your steel drilling operations, it might be time to audit your insert selection. Browse Accurate Cut’s selection of ISO P drilling solutions or contact our technical team—we can help you calculate the exact grade combination to lower your cost-per-hole.