Which Drill Insert Is Best for Stainless Steel

Drilling stainless steel is the ultimate test of patience and tooling. It is notorious for being “gummy” one second and work-hardening into an impenetrable wall the next. If your choice of insert isn’t perfect, you aren’t just looking at poor surface finish—you are looking at catastrophic tool failure, snapped drill bodies, and costly downtime.

At Accurate Cut, we know that “stainless steel” isn’t a single challenge; it’s a complex variable. The insert that cuts freely in 304 stainless might chip immediately in 17-4 PH. Finding the best drill insert isn’t about picking the most expensive option on the shelf. It is about matching the substrate, coating, and geometry to the unique thermal and mechanical properties of the material.

This guide breaks down the physics of drilling stainless steel and helps you identify exactly which insert grade will keep your production running and your cost-per-hole low.

Why Stainless Steel Destroys Standard Inserts

To choose the right tool, you have to understand the enemy. Stainless steel, particularly the austenitic 300-series (like 304 and 316), presents a specific set of metallurgical challenges that destroy standard general-purpose inserts.

1. Low Thermal Conductivity

Unlike drilling carbon steel, which helps carry heat away in the chip, stainless steel retains heat at the cutting interface. The heat has nowhere to go but into your insert. If your insert grade cannot withstand extreme thermal shock, the cutting edge will degrade rapidly.

2. Work Hardening

This is the biggest killer of drill inserts. As soon as a cutting edge dulls or “rubs” instead of shearing, the material hardens instantly. The drill is no longer cutting base metal; it is trying to cut a hardened skin that is often twice as hard as the original stock.

3. Built-Up Edge (BUE)

Stainless is ductile and sticky. It loves to weld itself to the cutting edge. This “built-up edge” alters the geometry of your insert, leading to poor chip evacuation and eventual breakage.

The Anatomy of the “Best” Insert: Three Critical Factors

When browsing the Accurate Cut catalog or specifying tooling for a new job, ignore the marketing fluff and look for these three technical specifications. If you are new to these tools, it may help to first review what drill inserts are and how they function in high-production environments.

1. The Substrate: Micro-Grain Carbide

For stainless steel, High-Speed Steel (HSS) is obsolete for indexable drilling. You need cemented carbide, specifically a micro-grain or ultra-fine grain substrate.

Why? Stainless requires a sharp edge to shear the material clean. Coarse-grain carbide requires a heavier hone (dulling) to prevent chipping, which causes rubbing. Fine-grain carbide allows for a sharper cutting edge that still retains the toughness needed to resist fracture.

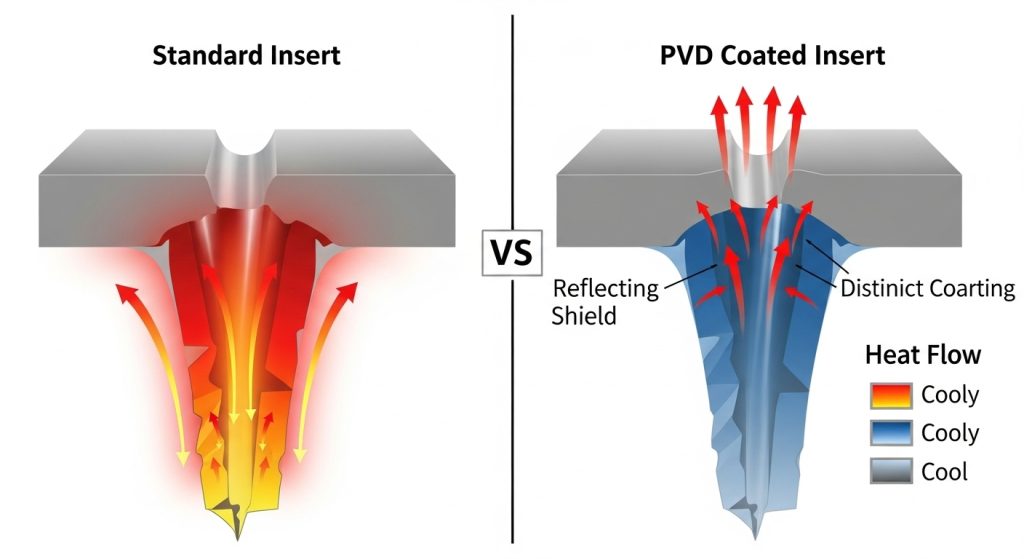

2. The Coating: PVD is King

The coating is your heat shield. For drilling stainless, Physical Vapor Deposition (PVD) coatings are almost universally superior to CVD (Chemical Vapor Deposition). PVD coatings are thinner and smoother, allowing for a sharper cutting edge that cuts rather than plows. For a detailed breakdown of chemistry, see our drill insert coatings guide.

Look for these specific coating chemistries:

- TiAlN (Titanium Aluminum Nitride): Excellent heat resistance. As it heats up, it forms an aluminum oxide layer that further protects the tool.

- AlCrN (Aluminum Chromium Nitride): The modern standard. It offers even higher heat resistance and a lower coefficient of friction, which is critical for preventing the “stickiness” that causes Built-Up Edge.

3. The Geometry: Positive and Polished

You want an insert labeled as “free cutting” or having “positive geometry.”

- High Rake Angle: Helps shear the sticky material away from the hole wall.

- Polished Flutes/Faces: Many premium inserts for stainless feature a post-coat polish. This slick surface helps evacuate those long, stringy chips that tend to pack the flutes in deep-hole drilling.

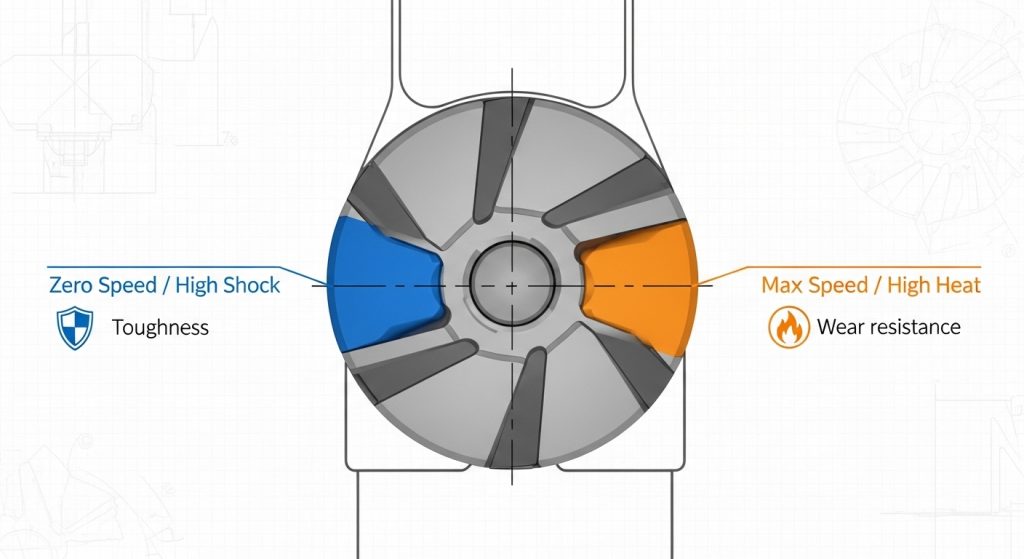

The Dual-Strategy: Center vs. Peripheral Inserts

Here is the insider secret that separates high-efficiency shops from the rest: You don’t always use the same insert for the whole drill.

In an indexable drill, the two inserts perform vastly different jobs:

- The Central Insert: Cuts at near-zero surface speed (at the very center). It deals with crushing forces and needs Toughness.

- The Peripheral (Outer) Insert: Cuts at maximum surface speed (SFM). It deals with high heat and friction and needs Wear Resistance.

The Accurate Cut Strategy:

For optimal performance in stainless steel, we often recommend a mixed grade strategy:

- Center Pocket: Use a tougher grade (often marked for ISO P or M/P) to resist shock.

- Peripheral Pocket: Use a harder, highly heat-resistant grade (optimized for ISO M/S) to resist thermal wear.

Matching Grades to Stainless Families

“Stainless” is a broad term. We categorize our recommendations based on the specific alloy you are machining.

Austenitic (300 Series, 304, 316)

- Challenge: Work hardening and heat generation.

- Best Insert: PVD AlCrN coated, fine-grain carbide with a sharp cutting edge.

- Goal: Keep moving. Never let the tool dwell.

Martensitic & Ferritic (400 Series, 416, 430)

- Challenge: Abrasive and often harder than 300 series, but chips break easier.

- Best Insert: You can often use a slightly harder substrate here. TiAlN coatings work effectively.

- Goal: Wear resistance.

Duplex and PH Stainless (2205, 17-4 PH)

- Challenge: High strength and high heat. These are the “tool killers.”

- Best Insert: Requires a specialized geometry designed for high-shear. Use the most heat-resistant PVD grade available.

- Goal: Thermal management.

Process Parameters: It’s Not Just the Insert

Even the world’s best insert will fail if the parameters aren’t tuned to the material’s behavior.

- Coolant is Mandatory: You cannot dry drill stainless steel with indexable inserts. High-pressure through-tool coolant is necessary not just for cooling, but to blast chips out of the hole. Recutting chips in stainless steel causes immediate catastrophic failure.

- Maintain Feed Rate: A common mistake is slowing down the feed when the drill sounds loud. This is fatal in stainless. You must maintain a feed rate (typically 0.003″ – 0.006″ per rev, depending on diameter) heavy enough to get the cutting edge under the work-hardened layer left by the previous rotation.

- Speed (SFM): Start conservative. For coated carbide in 304 stainless, 450-600 SFM is a standard starting window.

Common Failure Modes and How to Fix Them

If your current inserts are failing, the used edge tells a story. Here is how to read it:

- Built-Up Edge (Material welded to tip): Your cutting speed (SFM) is likely too low, or the coating isn’t lubricious enough. Increase speed or switch to an AlCrN coating.

- Chipping on the Outer Corner: The insert is too brittle or the feed is too high on entrance/exit. Switch the peripheral insert to a tougher grade.

- Flank Wear (Even abrasion): This is normal wear. If it happens too fast, switch to a harder, more wear-resistant grade.

Frequently Asked Questions

What is the best coating for drilling stainless steel?

The industry standard for drilling stainless steel is AlCrN (Aluminum Chromium Nitride) or TiAlN (Titanium Aluminum Nitride) applied via PVD. These coatings offer the high heat resistance and low friction needed to prevent the material from sticking to the tool.

What is the ISO grade for stainless steel?

Stainless steel falls under the ISO M (Yellow) classification. When buying inserts, look for the yellow “M” symbol on the box, which indicates the grade is optimized for the thermal and gummy characteristics of stainless alloys.

Why is my drill insert chipping in stainless steel?

Chipping usually occurs because of runout, lack of rigidity, or using a grade that is too hard. In stainless steel, chipping can also be caused by “dwelling”—letting the drill spin without feeding—which hardens the material until it shatters the insert edge.

Can I use the same insert for the center and periphery?

Yes, you can, and many general-purpose drills do. However, for high-volume production, using a specialized “tough” grade in the center and a “wear-resistant” grade on the periphery will significantly extend tool life and reduce cost per hole.

Should I peck drill with indexable inserts in stainless?

Generally, no. Indexable drills are designed to run continuously. Pecking can cause work hardening at the bottom of the hole every time the drill re-enters. If you are struggling to break chips, adjust your feed rate or check your coolant pressure rather than pecking.

Conclusion

Selecting the best drill insert for stainless steel is a balance of toughness and heat resistance. You need a micro-grain carbide substrate that can hold a sharp edge, protected by a high-performance PVD coating like AlCrN to manage the heat.

The “cheapest” insert is never the one with the lowest price tag—it’s the one that stays in the machine the longest. By choosing the right ISO M-class geometry and optimizing your feed rates to prevent work hardening, you turn a difficult material into a predictable, profitable process.

Ready to optimize your production?

At Accurate Cut, we specialize in high-performance tooling solutions. Browse our selection of ISO M Drill Inserts or contact our technical support team today to find the exact grade for your specific application.