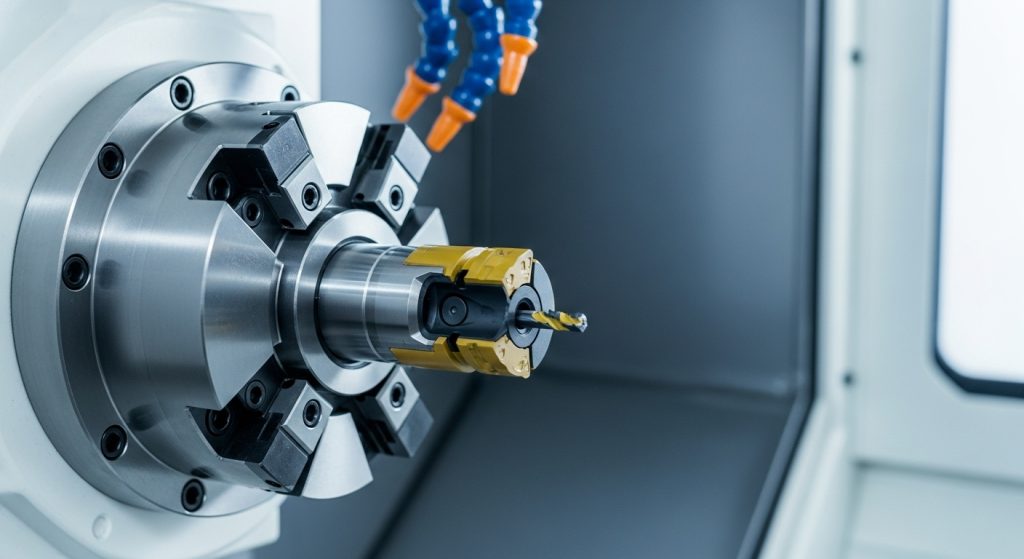

Which Toolholders Work Best for Indexable Drills? An Expert Guide to Rigidity and Runout

Determining which toolholders work best for indexable drills is the single most critical decision for holemaking stability. A high-performance drill body combined with a weak interface creates chatter, poor surface finish, and premature insert failure. You must prioritize rigidity and runout control to maximize your cost per hole.

I have spent years on shop floors watching expensive carbide drills fail. The culprit is rarely the drill itself. It is almost always a mismatch between the drill and the holder. When you push a 3xD or 5xD drill at high feed rates, the connection to the spindle must be rock solid.

This guide explores the specific mechanics of toolholding for indexable drilling. We will compare Side Lock, Hydraulic, Shrink Fit, and Collet systems to help you make the right choice.

What Is the Most Critical Factor When Choosing a Toolholder?

The most critical factors are gripping force and runout (TIR) accuracy.

For indexable drills, you need a holder that prevents pull-out forces and delivers high-pressure coolant directly to the cutting edge. Without extreme rigidity, the drill will deflect, causing oversized holes and rapid insert wear. Prioritize dampening and concentricity.

The Physics of the Cut

When an indexable drill enters the material, the forces are not just axial (up and down). Because indexable drills typically use a single effective cutting edge (or balanced inner/outer inserts), they generate significant side loads.

If your toolholder allows even 0.0005″ (12 microns) of movement, that vibration travels down the tool. In my experience, this kills insert life instantly.

- Rigidity: Resists the side deflection caused by the unbalanced cutting forces.

- Concentricity: Ensures the drill rotates on the true centerline of the spindle.

- Coolant Delivery: Essential for evacuating chips in deep holes.

If you are currently struggling with hole tolerance, check your CNC setup optimization guide. A rigid machine foundation means nothing if the toolholder is the weak link.

Side Lock (Weldon) Holders: Are They Still the Standard?

Side Lock holders remain the industry standard for general-purpose indexable drilling.

They mechanically lock the drill shank using a set screw that engages a flat ground onto the tool. This makes pull-out physically impossible, even under heavy feed rates. They are cost-effective, rugged, and easy for operators to set up quickly.

Why Weldon Works (and When it Doesn’t)

I often recommend Side Lock holders for roughing applications. When you are pushing a drill hard into 4140 steel, the “Weldon Shank” provides a mechanical safety net.

However, there is a trade-off. When you tighten that set screw, you push the drill shank off-center. This introduces a small amount of runout by design.

The Pros:

- Zero Pull-Out: The mechanical lock prevents the drill from being pulled out of the holder during retraction or pushed back during drilling.

- Simplicity: All you need is a hex key.

- Cost: Generally the most affordable option.

The Cons:

- Runout: The side pressure creates an unavoidable offset.

- RPM Limits: At very high speeds, the unbalance can cause vibration.

If you are running a job where hole tolerance is loose (+/- 0.005″), the Side Lock is unbeatable for reliability. However, if you are struggling with hole accuracy in CNC drilling, you may need to look at concentric systems like hydraulic chucks.

Hydraulic Chucks vs. Shrink Fit: Which Is Better for Drilling?

Hydraulic chucks generally offer the best balance of dampening and versatility for indexable drills.

While Shrink Fit offers the ultimate slim profile and low runout, Hydraulic chucks provide superior vibration dampening due to the oil chamber surrounding the bore. This dampening extends insert life significantly in interrupted cuts.

Deep Dive: The Battle for Precision

This is a debate I hear in tool cribs constantly. Let’s break it down by the mechanics.

Hydraulic Chucks:

These holders use a screw to compress an internal hydraulic reservoir. The pressure expands a bladder evenly around the tool shank.

- Dampening: The fluid layer acts as a shock absorber. In setup situations involving high feed rates, this absorbs the chatter before it reaches the spindle bearings.

- Runout: High-quality hydraulic chucks boast runout of less than 0.0001″.

Shrink Fit:

These use an induction heater to expand the holder bore, allowing the tool to drop in. As it cools, it shrinks around the tool.

- Rigidity: It is effectively a solid piece of steel.

- Access: The nose profile is very slim, great for tight fixtures.

My Verdict: For drilling, I prefer Hydraulic Chucks. The dampening characteristic helps smooth out the transition when the drill breaks through the material. Shrink fit is rigid, but sometimes too rigid, transferring harmonic vibrations back to the spindle.

Can You Use ER Collets for Indexable Drilling?

You should generally avoid standard ER collets for large-diameter indexable drills.

While accurate, collets rely on friction alone. They often lack the gripping force required to prevent the drill from pushing back into the holder under heavy axial loads. Use them only for smaller diameters (<12mm) or light finishing passes.

The Risk of Push-Back

I have seen this happen too many times. An operator sets up a 1-inch indexable drill in an ER40 collet. They hit the green button. The thrust load is massive. The drill overcomes the friction of the collet and pushes back inside the holder.

The result? The drill is now shorter than the offset says it is. The hole depth is wrong. Or worse, the drill slips rotationally, spinning inside the collet and welding itself to the holder.

If you must use a Collet Chuck:

- Use High-Torque Collets: Look for “Bearing Nut” collets that allow higher tightening torque.

- Cleanliness is King: Any oil on the collet taper reduces gripping force by 50%.

- Check Runout: Collets are great for runout, which helps with RPM setup and balance, but only if assembled perfectly.

| Feature | ER Collet | Side Lock | Hydraulic Chuck |

| Gripping Torque | Low/Medium | High (Mechanical) | High |

| Runout (TIR) | Good | Poor | Excellent |

| Dampening | Low | Low | Excellent |

| Pull-out Risk | High | Zero | Low |

| Best Use | Light Drilling | Heavy Roughing | Precision Drilling |

How Does Through-Spindle Coolant Affect Toolholder Choice?

Through-spindle coolant capability is mandatory for modern indexable drilling performance.

You must choose a toolholder that seals effectively at the shank to direct high-pressure coolant (minimum 300 PSI) through the drill body. Without this, chips pack in the flutes, causing catastrophic heat buildup and tool breakage.

The Sealing Mechanism Matters

Getting coolant to the cutting edge is non-negotiable. However, not all holders seal the same way.

- Side Lock: Usually seals well, but check the back-end screw.

- Hydraulic: inherently sealed.

- Collets: require “sealed collets” or specific sealing discs. Do not rely on standard slotted collets; the coolant will spray everywhere except down the drill.

If you are running indexable drills on machining centers, the coolant pressure is your lifeline. A leaking toolholder drops your pressure at the tip. If you lose pressure, you lose the ability to evacuate chips.

Pro Tip: If you see “smoke” instead of steam during a cut, your coolant isn’t reaching the tip. Check the toolholder seal immediately.

Lathe vs. Mill: Does the Machine Type Change the Choice?

Yes, the machine type dictates the toolholder interface and alignment requirements.

On a lathe, you are dealing with static blocks where alignment to the chuck center is paramount. On a mill, dynamic balance and spindle taper (CAT, BT, HSK) become the primary concerns for toolholder selection.

Lathe Considerations

When discussing how to use indexable drills on a lathe, we are usually talking about static blocks.

- Alignment: The drill must be perfectly on center. A Side Lock holder in a boring bar block is standard.

- Eccentric Sleeves: Some lathe holders allow you to rotate the drill slightly off-center. This is a handy trick to adjust the hole diameter by a few thousandths without changing the tool.

Mill Considerations

On a mill, the tool is spinning.

- Balance: At 10,000 RPM, a heavy Side Lock holder can vibrate.

- Taper Stiffness: Dual-contact (Big-Plus) or HSK tapers provide better rigidity than standard CAT40 tapers for long drills.

Power Milling Chucks: The Heavyweight Contender

Power milling chucks are the strongest option for large-diameter drilling applications.

They utilize a needle bearing system to generate immense gripping force, far exceeding collets or hydraulic chucks. While heavier and bulkier, they are the ideal choice for large indexable drills (over 1.5 inches) where torque is extreme.

When to Use Power Chucks

If you are drilling Inconel, Titanium, or hardened steels, the torque at the cutting edge is massive.

I recall a job involving 17-4 PH stainless. We kept spinning the drill in a hydraulic chuck. We switched to a Power Milling Chuck. The tool stopped slipping, and the chatter disappeared.

The downside is the size. They are bulky. You must verify your tool changer clearance before loading one up.

Frequently Asked Questions

Can I use a floating tap holder for drilling?

No, absolutely not. Floating holders have axial play designed for threads. Drilling requires rigid axial stability.

How tight should I torque a Side Lock screw?

Always use a torque wrench. Over-tightening deforms the holder bore. Under-tightening risks tool pull-out. Check the manufacturer’s spec, but it is usually higher than you think.

Does the pull stud matter?

Yes. A weak pull stud allows the holder to pull away from the spindle taper under load. Use high-strength studs and check them for cracks annually.

Conclusion: Making the Right Connection

Selecting the toolholders that work best for indexable drills is about matching the holder to the application.

- For General Roughing: Use Side Lock (Weldon). It is safe, cheap, and handles torque well.

- For Precision/Finishing: Use Hydraulic Chucks. They offer the best runout and dampening.

- For Heavy Metal Removal: Use Power Milling Chucks.

- Avoid: Standard ER Collets for anything larger than 0.5″.

Don’t let a $100 toolholder ruin the performance of a $500 drill body. Invest in rigidity, ensure your coolant delivery is sealed, and watch your tool life extend.