What to Check Before Buying Drill Inserts

Buying drill inserts seems like a straightforward task—find the part number, check the price, and click order. However, experienced manufacturing engineers know that the insert is the single most critical variable in the hole-making process. A mismatch between the insert grade and the application doesn’t just result in poor tool life; it often leads to catastrophic failure that destroys the expensive drill body and halts production. If you are already dealing with frequent failures, it is crucial to understand why drill inserts break before ordering replacements.

At AccurateCut, we approach tooling procurement as an engineering decision, not just a purchasing one. To ensure process security and maximize ROI, specific technical criteria must be evaluated before a purchase is made. This guide outlines the essential checklist for selecting the correct drill inserts for your specific application.

Check 1: System Compatibility (Proprietary vs. ISO)

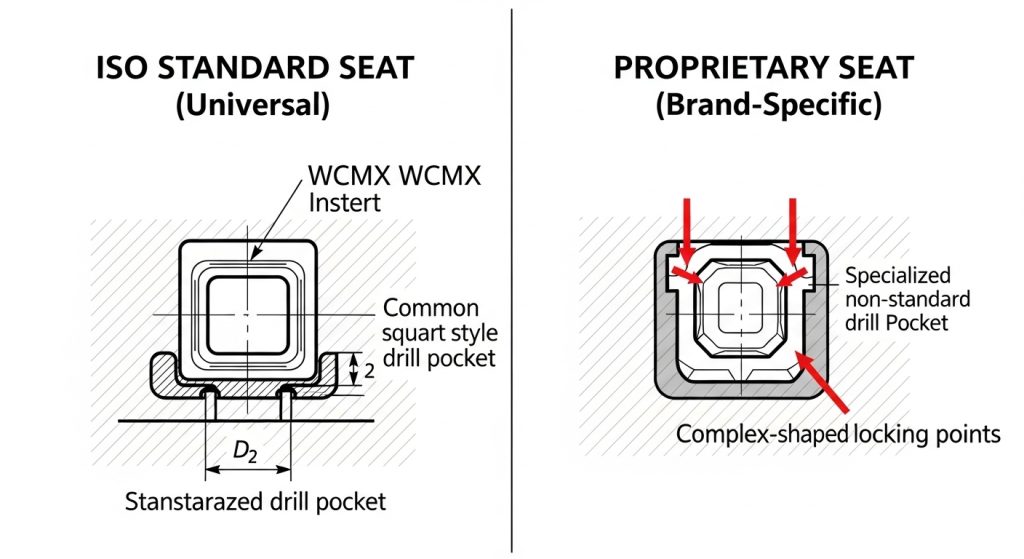

The first and most rigid constraint is the drill body interface. Unlike turning holders, which often accept standardized ISO inserts (like CNMG or WNMG), indexable drills frequently utilize proprietary designs to maximize rigidity.

Verify the Seat Interface

Before buying, confirm if your drill body accepts ISO-standard inserts (such as WCMX or SPMX) or if it requires a brand-specific geometry. Forcing a “near-fit” generic insert into a high-performance proprietary drill body will damage the insert pocket. Once the pocket is deformed, the drill body is effectively scrap. Poor seating can also lead to vibration issues; if you are seeing rough walls in your bores, review how to diagnose poor hole surface finish.

Check 2: Material Application (The ISO Standards)

“General Purpose” grades are rarely the most cost-effective solution for high-volume production. To optimize performance, the insert substrate and coating must match the specific ISO material group of the workpiece.

- ISO P (Steel): Requires a grade with high heat resistance to withstand the thermal loads of continuous cutting. Look for CVD coatings.

- ISO M (Stainless Steel): Requires a tougher substrate with a sharp edge and a PVD coating to prevent work hardening and built-up edge (BUE).

- ISO K (Cast Iron): Requires a hard, abrasive-resistant grade, often with a thick coating or ceramic content.

- ISO N (Non-Ferrous/Aluminum): Requires uncoated, highly polished carbide to ensure chip flow and prevent material welding.

Check 3: Inner vs. Outer Insert Roles

One of the most common mistakes in purchasing is buying a single box of inserts for a drill that requires two distinct grades. In modern indexable drilling, the central (inner) insert and the peripheral (outer) insert perform different physics.

The Inner Insert (Center)

The inner insert operates at near-zero surface footage (SFM) at the very center of the hole. It essentially crushes the material rather than shearing it.

- Requirement: It needs high toughness to resist chipping under pressure. If you see damage here frequently, learn how to prevent chipping in drill inserts.

The Outer Insert (Peripheral)

The outer insert runs at the drill’s maximum surface speed.

- Requirement: It needs high wear resistance to withstand heat and abrasion.

The Buying Strategy: For optimal results in tough materials like stainless steel, AccurateCut often recommends purchasing a “tough” grade for the inner pocket and a “wear-resistant” grade for the outer pocket.

Check 4: Coating and Grade Technology (PVD vs. CVD)

Understanding the coating technology is vital for predicting and extending indexable drill tool life. The method used to apply the coating changes the characteristics of the carbide edge.

PVD (Physical Vapor Deposition)

PVD coatings are thinner and adhere tightly to the substrate. This process allows the insert to maintain a sharper cutting edge.

- Best For: Stainless steel, superalloys, and applications requiring toughness (Inner inserts).

CVD (Chemical Vapor Deposition)

CVD coatings are thicker and provide a superior thermal barrier, insulating the carbide from high heat.

- Best For: High-speed drilling in carbon steels and cast iron (Outer inserts).

Check 5: Chipbreaker Geometry

A flat piece of carbide cannot evacuate chips from a deep hole. The topography on the top of the insert—the chipbreaker—determines whether chips form into manageable “6s and 9s” or dangerous long strings. If you struggle with evacuation, read our guide on how to fix chip packing during drilling.

Matching Geometry to Power

Aggressive chipbreakers designed for heavy roughing require significantly more machine horsepower and thrust. Before buying heavy-duty geometries, verify that the machine spindle has the torque to drive them. Conversely, “finishing” or “light” geometries reduce cutting forces but are more fragile.

Check 6: Economic Factors and Asset Protection

Price per insert is a misleading metric. The true cost calculation involves the “Cost Per Edge” and the risk to the drill body.

Count the Edges

Indexable drill inserts typically come with 2, 3, or 4 useable cutting edges. An insert that costs 20% more but offers 4 edges instead of 2 effectively cuts your tooling cost in half.

Protecting the Drill Body

Buying the cheapest insert often leads to premature breakage. When an insert fails inside a hole, it frequently destroys the drill body. Investing in high-quality inserts is essentially an insurance policy for your tool holder. For more details on preserving your drilling tools, refer to our industrial drill maintenance buying guide.

Conclusion

Selecting the right drill insert is not a generic administrative task; it is a technical specification that dictates the success of the machining operation. By validating system compatibility, matching ISO grades, distinguishing between inner and outer roles, and analyzing chipbreaker geometry, manufacturers can significantly reduce cycle times and scrap rates.

At AccurateCut, we provide tooling solutions engineered for stability and performance. Ensure your inventory is stocked with the correct grades to keep your spindles turning.

Frequently Asked Questions (FAQ)

Can I mix insert brands in the same drill body?

This is highly discouraged. While some inserts may physically fit, the geometry and tolerance of the insert seat are engineered for a specific brand’s insert. Mixing brands often results in poor seating, vibration, and damage to the drill body.

What happens if I use a steel grade for aluminum?

Using a coated steel grade for aluminum will likely result in failure. The coating creates friction that causes the aluminum to weld to the cutting edge (Built-Up Edge), clogging the flutes and potentially snapping the drill.

How do I identify if an insert is PVD or CVD?

Visually, CVD coatings (often TiCN/Al2O3) usually have a distinct gold or black appearance on the flank and top. PVD coatings (like TiAlN) often have a metallic sheen ranging from violet to grey. However, always consult the manufacturer’s grade chart for confirmation.

Why do insert descriptions have numbers like 04, 05, 06?

These numbers typically refer to the size of the insert (inscribed circle or cutting edge length) and the corner radius. It is critical to match these exactly to your drill body size; a size 06 insert will not fit a pocket designed for a size 05.