How to Choose the Right Drill Insert Grade

The sound of a drill failing deep inside a part is something you never forget. It’s not just the squeal—it’s that distinct, sickening “crunch” that tells you the insert didn’t just chip; it likely welded to the material and took the expensive drill body out with it.

In my 15 years on the shop floor, I’ve found that 90% of these catastrophic failures aren’t due to bad programming or poor runout. They happen because the insert grade was a mismatch for the application.

If you want the short answer, here it is: Choosing the right drill insert grade comes down to balancing two physical properties—hardness (wear resistance) and toughness (shock resistance). You must match the ISO material class (P, M, K) to your workpiece, then select a specific grade based on your setup’s rigidity. If your setup is unstable or vibration-prone, prioritize toughness. If you have a rigid setup and high heat, prioritize hardness.

Let’s cut through the confusing manufacturer catalogs and break down exactly how to pick the right grade, every time.

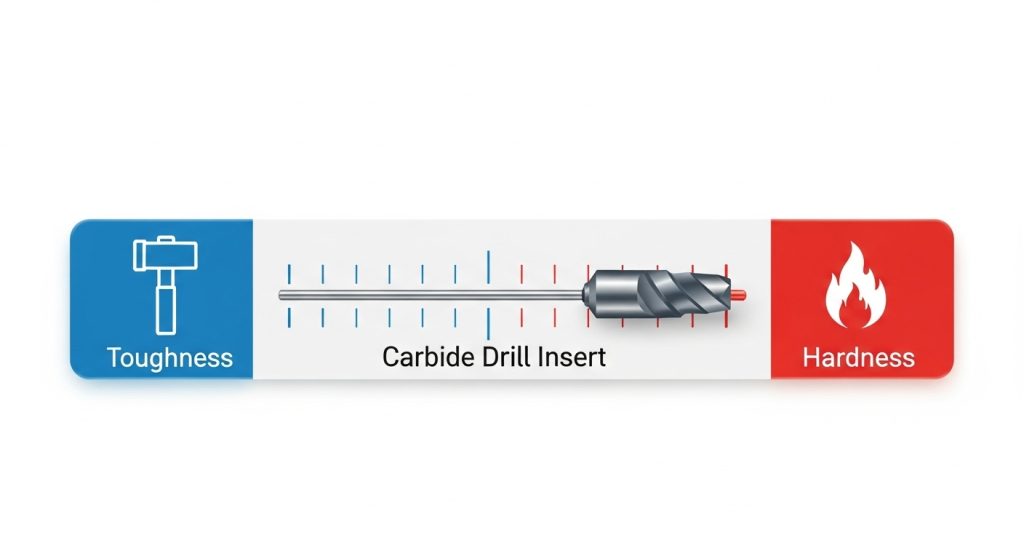

The Core Conflict: Hardness vs. Toughness

Before we look at color charts, you need to understand the physics of the carbide itself. If you are just getting started with indexable tooling, it helps to understand exactly what drill inserts are and how the substrate supports the cutting action. Every insert grade is a compromise between two opposing forces: Hardness and Toughness. You cannot have maximums of both simultaneously.

Think of it like this:

- Hardness: This is the insert’s ability to withstand heat and abrasive wear. A very hard grade is like glass—it’s incredibly scratch-resistant, but if you hit it with a hammer, it shatters.

- Toughness: This is the insert’s ability to absorb shock and vibration without fracturing. A tough grade is closer to hard rubber—it can take a beating, but it wears down faster.

In drilling, this balance is even more critical than in turning because the cutting edge is buried in the hole. The heat has nowhere to go but into the tool and the chip.

The Golden Rule of Drilling: If you are unsure, start with a tougher grade. A grade that is too soft will just wear out faster (predictable failure). A grade that is too hard will shatter instantly (catastrophic failure).

Decoding the ISO Material Color Chart

If you’ve ever looked at the back of an insert box, you’ve seen the letters P, M, K, N, S, and H. This isn’t just packaging decoration; it’s the ISO 513 classification system. It is the universal map for machinists.

While manufacturers love to give their grades fancy proprietary names (like “GC4325” or “KC725M”), they all map back to these standards.

ISO P (Blue) – Steels

This is your bread and butter. Carbon steels, alloy steels, and tool steels. The main enemy here is heat.

- What you need: A grade with a balance of toughness and thermal shock resistance.

- The Coating: Usually TiCN or Al2O3 (Aluminum Oxide) to block heat.

ISO M (Yellow) – Stainless Steels

Stainless is tricky. It doesn’t conduct heat well, so all the heat stays in the cutting edge. It also tends to be “gummy,” leading to Built-Up Edge (BUE), where material welds to the insert.

- What you need: A sharp edge (PVD coating) and a fine-grain substrate that resists thermal cracking.

- The Secret: Don’t run a dull or heavily honed insert in stainless; it will work-harden the material instantly.

ISO K (Red) – Cast Iron

Cast iron creates short chips and is very abrasive. It doesn’t generate as much heat as steel, but it eats edges like sandpaper.

- What you need: High hardness. You want a thick, hard coating to resist abrasion. You can usually run these grades very fast.

Quick Reference Table: ISO Grades for Drilling

| ISO Class | Color | Material | Primary Failure Mode | Recommended Grade Focus |

| P | Blue | Steel | Thermal Crater Wear | Balanced Hardness/Toughness |

| M | Yellow | Stainless | Built-Up Edge / Notching | Sharp Edge + Thermal Resistance |

| K | Red | Cast Iron | Abrasive Flank Wear | High Hardness |

| N | Green | Aluminum | BUE / Adhesion | Uncoated or DLC (Diamond-Like) |

| S | Orange | Superalloys | Extreme Heat / Notching | High Toughness + Heat Resistance |

| H | Gray | Hardened | Plastic Deformation | Extreme Hardness (CBN/Ceramic) |

The Secret Sauce: Understanding Coatings

The substrate (the carbide itself) is the skeleton, but the coating is the skin. In drilling operations, the choice between CVD and PVD coatings is distinct from turning. For a comprehensive breakdown of the chemistry involved, check out our drill insert coatings guide.

PVD (Physical Vapor Deposition):

In my experience, PVD is the king of drilling. The coating is thinner and adheres better to sharp edges. Since drilling relies heavily on the shearing action at the center of the drill (where surface footage is near zero), you need that sharp edge. PVD coatings like TiAlN (Titanium Aluminum Nitride) are standard because they form a protective oxide layer when they get hot.

CVD (Chemical Vapor Deposition):

These coatings are thicker and offer incredible heat protection. They are great for turning applications where the insert stays in the cut for minutes at a time. However, in drilling, the thicker coating usually requires a more rounded edge (hone), which increases cutting pressure. Use CVD only for high-speed drilling in stable conditions on cast iron or steel.

Step-by-Step Guide to Selection

Stop guessing. Follow this workflow when you’re standing at the vending machine or looking through the catalog.

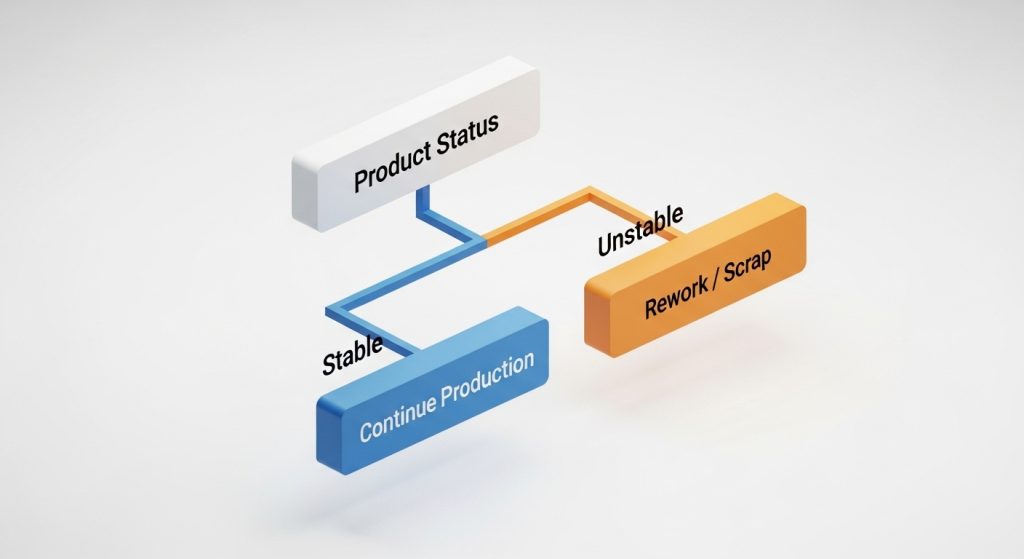

Step 1: Define the Stability

This is the step most people skip. Look at your machine and the part.

- Is the workpiece clamped solidly, or is it hanging off a fixture?

- Are you drilling through a cross-hole or an uneven surface?

- Is the machine spindle older with some runout?

- The Verdict: If you answered “Yes” to any instability, choose a tougher grade. Do not chase the hardest grade for speed; it will chip.

Step 2: Check the Coolant

Drilling is a confined cut. The heat is trapped.

- Through-Spindle Coolant: You can afford to run harder, more heat-resistant grades because the coolant is evacuating chips and heat effectively.

- Flood Coolant: The thermal cycling is more severe (hot-cold-hot-cold). You need a grade with better thermal shock resistance (tougher substrate) to prevent “comb cracks” on the edge.

Step 3: Pick the Grade

Now combine the ISO class with your stability assessment.

- Stable Steel Setup: Pick a “P15” or “P20” equivalent grade (Harder).

- Unstable Stainless Setup: Pick an “M30” or “M40” equivalent grade (Tougher).

Note on Numbers: In ISO, lower numbers (05, 10) are Harder. Higher numbers (30, 40) are Tougher.

Troubleshooting: Reading the Dead Insert

Your used inserts are the best data source you have. Don’t just throw them in the scrap bin; perform an autopsy. The wear pattern tells you exactly what to change next time.

1. Flank Wear (Even wear on the cutting edge)

- Diagnosis: This is normal. You used the tool correctly.

- Action: If it happened too fast (e.g., 100 holes instead of 500), move to a Harder Grade.

2. Chipping or Fracture (Pieces of the edge missing)

- Diagnosis: The grade was too brittle for the cut, or the setup wasn’t stable.

- Action: Move to a Tougher Grade. Reduce your feed rate slightly on entry/exit.

3. Built-Up Edge (Material welded to the tip)

- Diagnosis: Common in Aluminum and Stainless. The material is sticking because of heat or friction.

- Action: You need a coating with better lubricity (smoother) or a sharper edge. Increase your cutting speed (RPM) to push the heat into the chip, not the tool.

4. Thermal Cracking (Vertical cracks perpendicular to the edge)

- Diagnosis: The insert is getting hot, then cold, then hot rapidly.

- Action: Use a grade with better thermal shock resistance (often a PVD grade) or check that your coolant supply isn’t intermittent.

FAQ

What is the difference between PVD and CVD coatings for drilling?

PVD coatings are thinner and allow for sharper cutting edges, which decreases cutting pressure—ideal for the low-surface-speed center of a drill. CVD coatings are thicker and better for heat resistance but generally require a honed (rounded) edge, which increases pressure. PVD is generally preferred for drilling stainless and superalloys.

Can I use a steel grade (ISO P) for drilling Cast Iron?

You can, but it’s not optimal. Cast iron is abrasive, not gummy. A steel grade is designed to resist heat cratering, whereas a Cast Iron (ISO K) grade is designed to resist pure abrasion. Using a steel grade on iron will likely result in rapid flank wear.

How do I know if my drill insert is too hard?

If your insert is failing by chipping, fracturing, or snapping before it shows signs of abrasive wear, it is likely too hard. A grade that is too hard cannot withstand the vibrations of drilling and will shatter rather than wear down smoothly.

Why do stainless steel drills fail so quickly?

Stainless steel work-hardens. If you dwell (spin without feeding) even for a second, the material hardens instantly. Combined with a grade that isn’t sharp enough, this creates extreme heat and friction. Use an ISO M grade with a sharp edge and maintain a constant feed rate.

What does the number mean in ISO grades (e.g., P25 vs P40)?

The number indicates the balance of hardness vs. toughness. Lower numbers (P05, P10) are harder and more wear-resistant but brittle. Higher numbers (P30, P40) are tougher and more shock-resistant but wear faster. For general drilling, P25 is often a good starting point.

Conclusion

Selecting the right drill insert grade isn’t about memorizing a specific catalog number; it’s about understanding the application. You are managing a relationship between the heat of the cut and the stability of your machine.

Remember, a “better” grade isn’t always the one that costs more or has the newest coating technology. The best grade is the one that finishes the batch without surprising you.

The Bottom Line: If you are chasing cycle time in a high-volume, stable production run, push toward harder grades (lower ISO numbers). If you are a job shop running small batches on varying machines, prioritize toughness (higher ISO numbers). It is always cheaper to index a worn insert than to replace a blown-up drill body.

Next Step: Go to your tool crib today and pull your three most commonly used drill inserts. Look up their ISO classification. Are you running a “P40” (Tough) grade on high-speed production steel? If so, you’re leaving money on the table. Time to optimize.