Which Coatings Are Best for Tough Materials? The Definitive Guide

Selecting the correct coating for tough materials determines the difference between a profitable job and a scrapped part. When machining hardened steels, superalloys, or cast iron, the tool coating acts as the primary heat shield. It prevents chemical interactions and extends the lifespan of your substrate. This guide compares the top coatings to help you optimize performance.

What Makes a Material “Tough” to Machine?

Tough materials, such as hardened tool steels, stainless steel, and nickel-based superalloys, generate immense heat and cutting forces. They often possess high tensile strength and abrasiveness. To cut them effectively, your tool coating must offer extreme heat resistance, high surface hardness (Vickers), and a low coefficient of friction to evacuate chips quickly.

Understanding the Mechanics of Toughness

When we talk about “tough” materials in a machine shop, we aren’t just talking about hardness on the Rockwell C scale. We are talking about the material’s behavior during deformation.

- Work Hardening: Materials like Stainless Steel harden instantly as they are cut. If your tool dwells or the coating fails, the material becomes harder than the drill itself. For specific strategies on this, review our guide on how to drill stainless steel.

- Heat Generation: Tough materials conduct heat poorly. Instead of the heat leaving with the chip, it stays in the tool. Your coating must act as a thermal barrier.

- Abrasiveness: Cast iron, for example, is highly abrasive. It wears down the cutting edge physically rather than chemically. You can learn more about managing this in our cast iron drilling guide.

Why Is AlTiN Considered the King of Tough Material Coatings?

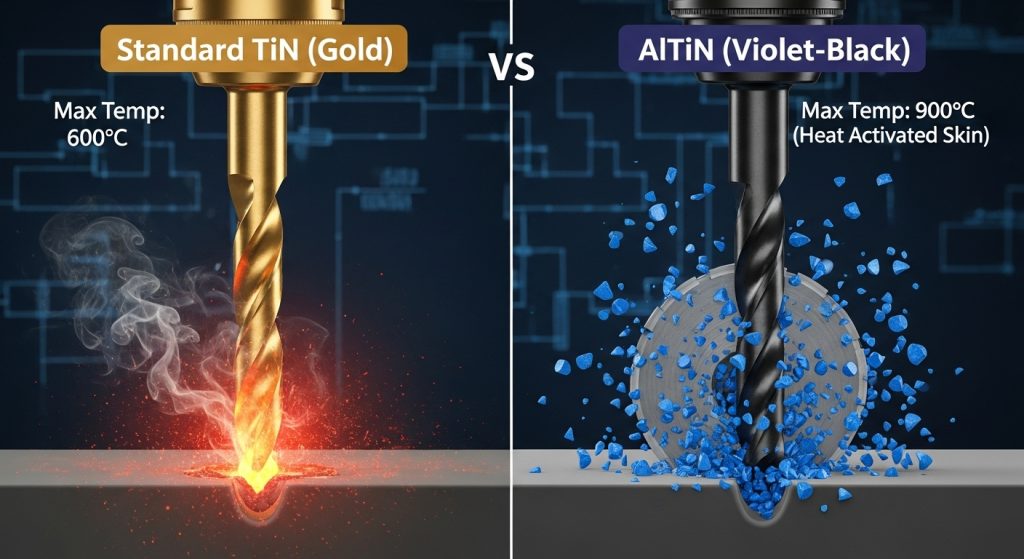

AlTiN (Aluminum Titanium Nitride) is widely regarded as the best coating for tough materials like hardened steel and cast iron. It boasts an oxidation temperature of up to 900°C (1650°F). When heated, the aluminum in the coating forms a protective oxide layer, making it harder and more heat-resistant during the cut.

The Aluminum Oxide “Skin” Effect

AlTiN is distinctively violet-black. Its “superpower” is dry machining. Unlike older coatings that rely on coolant, AlTiN actually performs better when it gets hot. The heat triggers the formation of a hard ceramic surface layer.

If you are running high-speed machining (HSM) operations on materials above 45 HRC, AlTiN or its variant TiAlN (Titanium Aluminum Nitride) are your best options. They prevent the heat from reaching the carbide substrate. This is critical when you are learning how to drill hardened materials.

Key Specs for AlTiN:

- Hardness: ~3300-3500 HV

- Max Temp: 900°C

- Best For: Hardened steel, dry machining, high-speed applications.

How Does TiCN Perform on Abrasive Tough Materials?

TiCN (Titanium Carbonitride) is the ideal coating for tough materials that are abrasive or “sticky,” such as stainless steel or aluminum alloys. The addition of carbon increases surface hardness significantly over standard TiN. It also lowers the friction coefficient, which helps prevent the material from welding to the cutting edge (Built-Up Edge).

Balancing Hardness and Lubricity

TiCN usually appears blue-grey or pinkish. While it doesn’t handle heat quite as well as AlTiN (it oxidizes around 400°C), it is harder at room temperature. This makes it excellent for:

- Threading and Tapping: Where torque is high and speed is low.

- Stainless Steel: It helps the gummy chips slide off the tool.

- Interrupted Cuts: It offers good toughness to resist chipping.

If you are working with sticky alloys or need a robust insert for alloy steel, TiCN is often a reliable middle-ground choice.

Can You Use TiN Coating for Tough Applications?

TiN (Titanium Nitride) is generally suitable for general-purpose machining but struggles with truly tough, hardened materials. While it reduces friction and looks impressive (gold color), it has a lower heat limit (600°C) and lower hardness compared to AlTiN or TiCN. It is best used for softer steels or when running at lower speeds.

The Limits of the “Gold Standard”

I have seen many machinists try to push a standard Gold TiN drill through 4140 pre-hardened steel at high speeds. The result is almost always premature failure. TiN is excellent for standard carbon steel applications, but once you enter the realm of tool steels or superalloys, the heat destroys the coating quickly.

Comparison Table: Coating Performance

| Coating | Color | Hardness (HV) | Max Temp | Best For |

| TiN | Gold | ~2300 | 600°C | General steel, low speed |

| TiCN | Blue-Grey | ~3000 | 400°C | Stainless, abrasive, sticky |

| TiAlN | Violet | ~3300 | 800°C | Hardened steel, dry cuts |

| AlTiN | Black | ~3600 | 900°C | Extremely tough/hard materials |

What Role Does Coating Thickness Play in Tool Life?

Thinner coatings (2-3 microns) generally offer better edge retention for finishing tough materials, while thicker coatings (4+ microns) provide wear resistance for roughing. However, on very tough materials, a coating that is too thick can delaminate (peel off) due to the extreme cutting pressures and heat cycles involved.

PVD vs. CVD Processes

The application method matters as much as the material.

- PVD (Physical Vapor Deposition): This creates a thinner, smoother coating. It is essential for sharp edges. If you are browsing our material-based drilling guides, you will notice PVD is preferred for solid carbide drills used in tough materials.

- CVD (Chemical Vapor Deposition): Creates a thicker, stronger bond. This is often used on indexable inserts for turning cast iron or heavy roughing of steel.

When Should You Avoid Coatings Entirely?

You should avoid coatings on tough materials primarily when machining non-ferrous metals that react with the coating, or when an ultra-sharp edge is required. For example, using a TiN coating on Titanium can cause chemical affinity (galling), as they share similar properties. In some plastics or aluminum, a polished, uncoated carbide tool cuts cleaner.

The “Sharpness” Trade-off

Coatings add size to the tool. While microscopic, this dulls the cutting edge slightly. When machining extremely tough but soft materials (like gummy titanium), a dull edge causes work hardening. Sometimes, a highly polished, uncoated tool—or a specialized thin DLC (Diamond-Like Carbon) coating—is better.

However, for most ferrous tough materials (steels and irons), running uncoated is a recipe for disaster. The heat barrier is simply too valuable to skip.

Practical Checklist: Matching Coating to Application

When you are setting up your next job, run through this quick selector to ensure you aren’t setting your tool up to fail.

- Is it Hardened Steel (>45 HRC)?

- Choice: AlTiN or TiAlN.

- Reason: You need the heat resistance. Run it dry or with air blast to activate the coating.

- Is it Stainless Steel (304/316)?

- Choice: TiAlN or Multi-layer TiCN.

- Reason: You need to prevent BUE (gumminess) and handle the work hardening.

- Is it Cast Iron?

- Choice: Thick AlTiN or CVD-coated inserts.

- Reason: You need abrasion resistance.

- Is it Alloy Steel (4140/4340)?

- Choice: TiCN or TiAlN.

- Reason: A balance of toughness and heat resistance.

For a deeper dive into specific tooling setups, check our comprehensive hub on material-based drilling guides.

Conclusion

There is no single “magic bullet” coating. The coating for tough materials that works best depends entirely on heat management. If you are generating high heat (hardened steel), go with AlTiN. If you are fighting abrasion and stickiness (stainless), look toward TiCN or specialized multi-layers. By matching the thermal properties of the coating to the mechanics of the material, you ensure your tools stay sharp and your process stays profitable.