How to Compare Indexable Drill Brands

A famous logo doesn’t drill the hole—geometry and physics do. In the machining world, it is easy to default to the “Big Brands” out of habit or perceived safety. However, paying a premium for a marketing budget does not guarantee that the tool is optimized for your specific application. Conversely, buying “budget” drills often leads to hidden costs in the form of scrap and downtime.

At AccurateCut, we believe that procurement decisions should be based on engineering specs, not brand loyalty. To truly evaluate the performance potential of a tool, you need to look past the box and inspect the steel. This guide provides a technical framework on how to compare indexable drill brands objectively, ensuring you invest in rigidity, longevity, and true value.

Point 1: Drill Body Rigidity (The Core Analysis)

The most critical feature of an indexable drill is not the insert—it is the body that holds it. If the drill body flexes under load, the inserts will chip regardless of their grade. When comparing two brands, look at the core web thickness.

Core Thickness and Straightness

A drill with a thicker central web resists torsion and deflection. “Budget” brands often reduce the core diameter to make flute grinding easier, but this compromises stability. A flexible body causes the drill to wander, which is a primary cause when diagnosing poor hole surface finish.

Shank Tolerance

Check the shank specifications. A high-quality drill brand will grind shanks to an ISO h6 tolerance to ensure near-zero runout in the holder. If a brand only offers standard turned shanks without precision grinding, you will fight runout issues that drastically shorten tool life.

Point 2: The Insert Pocket Design (The Critical Interface)

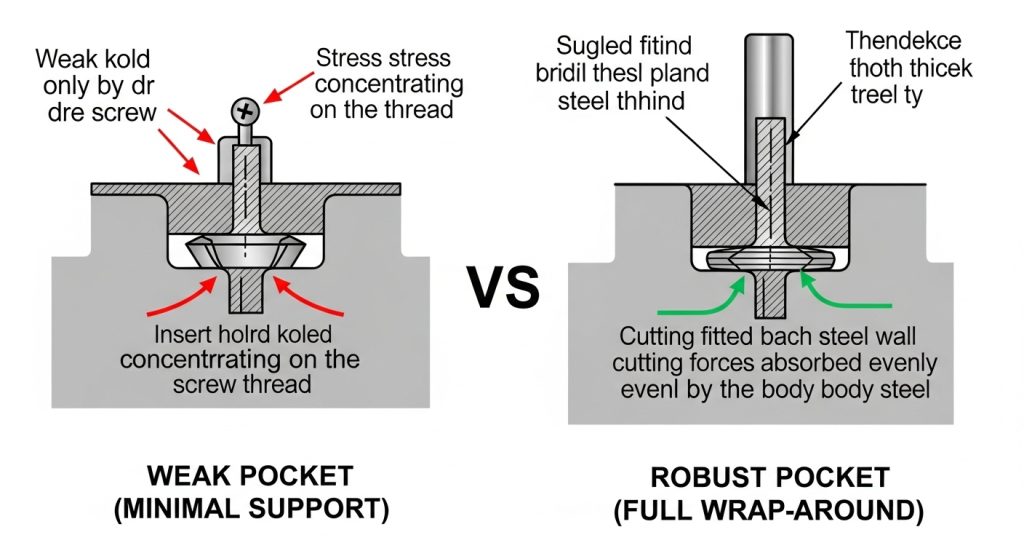

The pocket is the weakest link in any indexable drill. It is the point where cutting forces are transferred from the insert to the steel body. If the pocket deforms, the insert moves. If the insert moves, it breaks.

Clamping Mechanism

Compare the screw angles. Superior brands design the screw hole at a slight angle to the insert hole. When tightened, this “pull-back” effect forces the insert firmly against the pocket walls, locking it in two directions. Inferior brands rely solely on the screw head for downward pressure, allowing lateral movement during high-feed cuts.

Support Surface

Look at how much steel supports the back of the insert. A “Robust Pocket” wraps around the insert, absorbing the thrust load. A “Weak Pocket” leaves the insert unsupported, leading to vibration and micro-fractures.

Point 3: Chip Evacuation Capabilities

Once the chip is created, it must be evacuated immediately. If chips jam in the flutes, the heat spikes, and catastrophic failure follows. Effective chip evacuation is the key to extending indexable drill tool life.

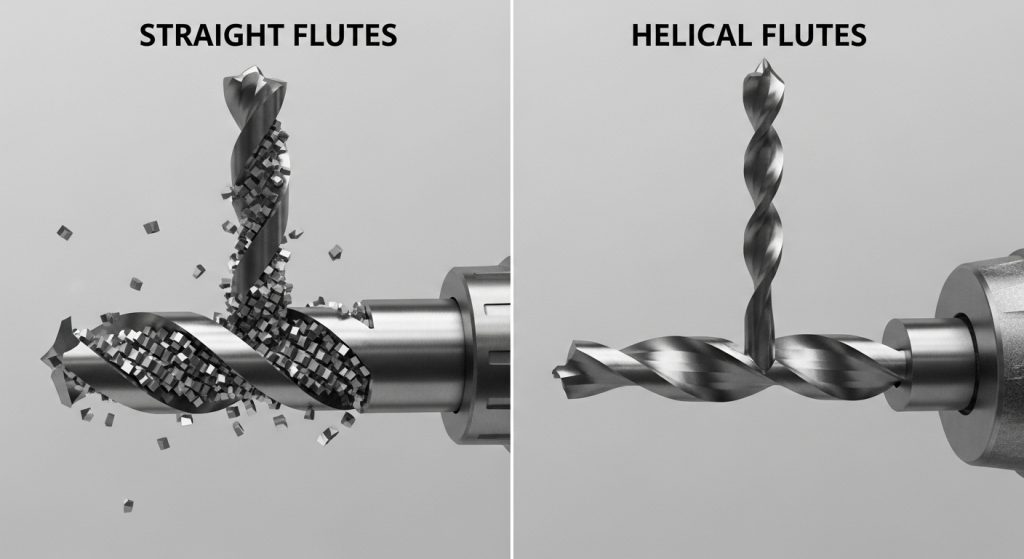

Helical vs. Straight Flutes

- Straight Flutes: Cheaper to manufacture. They rely entirely on coolant pressure to push chips out.

- Helical (Twisted) Flutes: These act like an Archimedes screw, mechanically lifting chips out of the hole. For depths greater than 3x Diameter, helical flutes offer superior security against packing.

Surface Polish

Run your finger down the flute (carefully). A polished, mirror-like finish reduces friction, allowing chips to slide effortlessly. A rough, milled finish creates drag points where chips can snag and weld. If you frequently struggle with jams, reviewing how to fix chip packing during drilling can help, but switching to a brand with polished flutes is often the permanent cure.

Point 4: System Flexibility (ISO vs. Captive)

When you buy a drill body, you are entering a long-term relationship with that insert style.

The “Captive” Trap

Many brands design proprietary “captive” pocket shapes that only accept their specific inserts. This locks you into their supply chain and pricing structure. If they raise prices or go out of stock, your production stops.

The ISO Advantage

Brands that utilize ISO-compatible geometries (like WCMX or SPMX) offer supply chain security. While proprietary geometries can offer performance benefits in niche applications, an ISO-standard system provides flexibility and competitive sourcing options. This is a vital factor to consider in your checklist of what to check before buying drill inserts. Furthermore, ensuring you have a reliable drill insert supplier who stocks these ISO standards is essential for maintaining production uptime.

Point 5: The “Total Cost of Ownership” (TCO) Math

Finally, compare the economics. Don’t be fooled by the sticker price of the drill body. The real cost is the “Cost Per Hole.”

The “Free Drill” Promotion

Be wary of promotions offering “Buy 10 boxes of inserts, get the drill body free.” Often, the inserts in these deals are priced 30% higher than the market average. Over the life of the tool, you will pay for that “free” body ten times over.

Calculating ROI

To find the true value, verify how many edges the inserts offer (4 edges is cheaper than 2) and how durable the drill body steel is. A body that survives 50 insert changes is cheaper than a budget body that wears out after 10, regardless of the initial purchase price. For tips on protecting that asset, refer to our industrial drill maintenance buying guide.

Conclusion

The best drill brand is not necessarily the one with the biggest catalog; it is the one that balances rigidity, pocket security, and economic transparency. By inspecting the core thickness, validating the pocket support, and calculating the true cost per edge, you can confidently select a partner that drives your productivity.

At AccurateCut, we welcome the side-by-side comparison. We engineer our tools to withstand the scrutiny of the toughest engineering evaluations.

Frequently Asked Questions (FAQ)

Are expensive drill bodies worth the extra cost?

Generally, yes, if the cost goes into the material science. Premium bodies use hardened tool steel (often HRC 45+) which resists pocket deformation and erosion from chips. This longevity lowers the long-term cost per hole compared to softer, cheaper bodies.

Should I stick to one brand for all my drilling?

Standardizing can simplify inventory, but it isn’t always optimal. You might use a premium brand like AccurateCut for challenging materials (Stainless, Inconel) where rigidity is paramount, and a general-purpose brand for aluminum or plastics.

How do I measure drill body runout?

Mount the drill in a high-quality collet or hydraulic chuck. Place a dial test indicator on the cylindrical shank of the drill (near the flange) and rotate the spindle by hand. Total Indicator Runout (TIR) should ideally be under 0.0005″ (0.012mm).

What is the difference between helical and straight flutes?

Helical flutes are twisted around the body, helping to mechanically lift chips out of the hole, which is critical for deep drilling. Straight flutes are linear and rely mostly on coolant pressure to flush chips, which is usually sufficient for short (2xD) holes but risky for deeper applications.