What Is the Difference Between PVD and CVD

In precision manufacturing, the difference between a component that fails in a week and one that lasts for months often comes down to just a few microns of surface material.

When you are specifying a coating for cutting tools, molds, or wear parts, you will almost certainly face the choice between PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition). While both processes deposit thin, hard layers (like Titanium Nitride or Diamond-Like Carbon) onto a substrate to improve performance, they achieve this through fundamentally different mechanisms.

Choosing the wrong method isn’t just a cosmetic issue. It can lead to warped parts, softened substrates, or coatings that peel off under stress. At Accurate Cut, we understand that the “best” coating depends entirely on the application—whether you need to maintain a razor-sharp cutting edge or coat the inside of a complex die.

This guide breaks down the technical differences, thermal limitations, and performance characteristics of PVD vs. CVD to help you make the right decision for your drill inserts and production line.

The Quick Answer: PVD vs. CVD at a Glance

If you are in a rush, here is the bottom line:

PVD is a low-temperature process that vaporizes solid material to coat a part. It is ideal for sharp cutting edges and heat-sensitive metals (like High-Speed Steel) because it produces a thin, smooth coating without softening the part.

CVD is a high-temperature process that uses chemical gas reactions. It creates a thicker, extremely hard coating that bonds chemically to the surface. It is best for heavy-duty wear parts and complex shapes where the gas needs to reach internal cavities, provided the base material can withstand high heat.

Comparison of Key Specifications

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

| Process State | Physical (Solid $\to$ Gas $\to$ Solid) | Chemical (Gas Reaction) |

| Process Temp | Low ($250^\circ\text{C}$ – $600^\circ\text{C}$) | High ($600^\circ\text{C}$ – $1000^\circ\text{C}$) |

| Coating Thickness | Thin (1 – 5 microns) | Thick (5 – 20 microns) |

| Adhesion Type | Physical bonding | Chemical bonding |

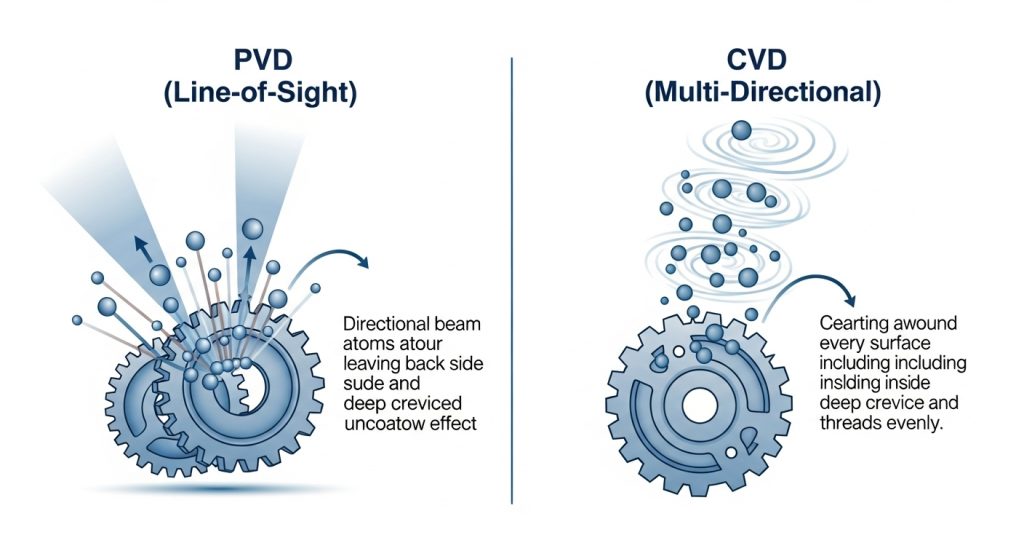

| Internal Coverage | Poor (Line-of-sight only) | Excellent (Multi-directional) |

| Primary Stress | Compressive (Resists cracking) | Tensile (Harder, but brittle) |

What Is PVD (Physical Vapor Deposition)?

Physical Vapor Deposition describes a variety of vacuum deposition methods used to produce thin films. The key word here is Physical. We aren’t relying on a chemical reaction to create the coating material; we are physically blasting a solid source material into a vapor and letting it settle on your part.

The Process

The process takes place in a high-vacuum chamber. A solid “target” material (like Titanium) is vaporized—often using a high-power electric arc or plasma. This vaporized metal travels through the vacuum and condenses on the substrate (your part), returning to a solid state. Reactive gases like nitrogen can be introduced during this transit to create compounds like Titanium Nitride (TiN).

Key Characteristics

- Low Temperature: Because PVD typically operates below $500^\circ\text{C}$, it is the safest option for substrate materials that might lose their temper or warp at higher heats.

- Line-of-Sight Limitation: PVD is a “line-of-sight” process. Imagine spray painting a fence; you can only coat what you can see. To coat complex 3D parts, the parts must be rotated on complex fixtures within the vacuum chamber to ensure coverage.

- Thin & Smooth: PVD coatings are incredibly thin (often 2-5 microns). This allows the coating to perfectly replicate the surface finish of the tool underneath, maintaining sharp cutting edges.

What Is CVD (Chemical Vapor Deposition)?

Chemical Vapor Deposition is the older, more robust sibling in the coating family. Instead of vaporizing a solid, this process introduces gaseous precursors into a heated reactor chamber.

The Process

In CVD, your parts are heated to extreme temperatures. Gases flow into the chamber and chemically react directly on the hot surface of the substrate. This reaction bonds the coating layer to the substrate at a molecular level.

Key Characteristics

- High Temperature: CVD requires temperatures ranging from $900^\circ\text{C}$ to $1050^\circ\text{C}$ to trigger the necessary chemical reactions.

- Multi-Directional Flow: Gases flow like air—they fill every nook and cranny. This means CVD requires no complex rotation fixtures and is excellent for coating internal threads, deep recesses, or complex geometries that PVD can’t reach.

- Thick & Hard: CVD coatings are generally much thicker (5-20 microns). This provides a massive reservoir of wear-resistant material, making it ideal for heavy roughing operations where tool life is prioritized when you choose the right drill insert grade.

Detailed Comparison: The 4 Critical Differences

When we consult on manufacturing projects, we look at four specific factors to determine which process wins: Temperature, Edge Retention, Stress, and Environment.

Temperature and Substrate Impact

This is the most common failure point we see in the industry.

Because CVD operates at temperatures up to $1000^\circ\text{C}$, it exceeds the tempering point of many steels. If you put standard High-Speed Steel (HSS) tooling through a CVD process, the coating will adhere beautifully, but the tool itself will anneal (soften). You end up with a hard shell over a soft core, leading to immediate tool failure.

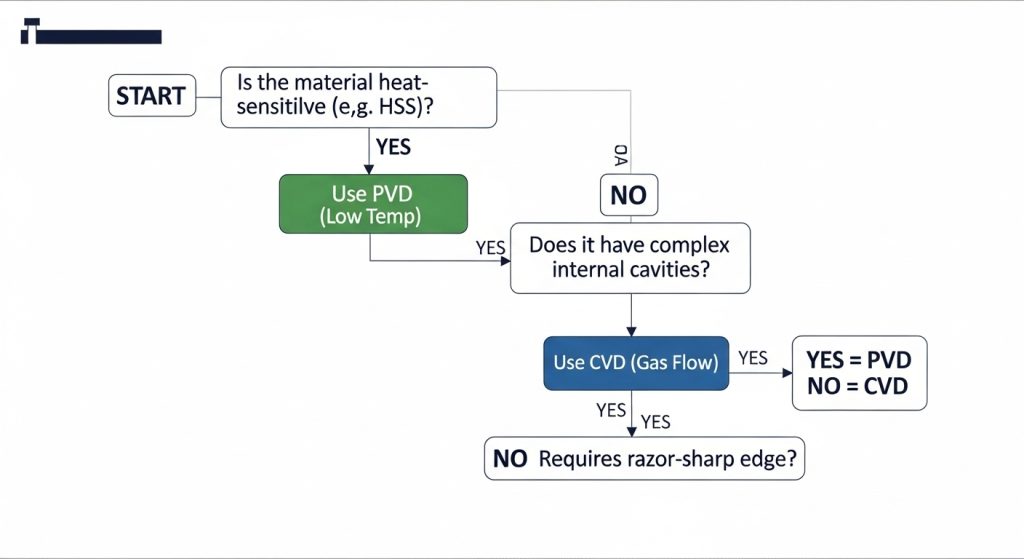

The Verdict: Use CVD almost exclusively for Cemented Carbides that can withstand the heat. Use PVD for HSS and best drill inserts for steel applications where preserving the substrate’s hardness is critical.

Coating Thickness and Edge Sharpness

In precision cutting, “sharper” isn’t always better, but “controlled” is.

Since CVD coatings are thicker (up to 20 microns), they tend to round off the cutting edge slightly. If you are roughing out cast iron, this is actually a benefit—the rounded edge is stronger. However, for finish machining or cutting sticky materials like aluminum or stainless steel, you need a razor-sharp edge to prevent material build-up.

The Verdict: PVD is superior for finishing tools and applications requiring a sharp cutting edge. CVD is the king of heavy roughing.

Adhesion and Stress Mechanics

This is a technical nuance often overlooked. PVD coatings typically possess compressive stress. Imagine the coating pushing together tightly on the surface. This compressive force actually helps prevent micro-cracks from propagating effectively, making the tool “tougher.”

CVD coatings, due to the high heat and subsequent cooling (mismatch in thermal expansion), often carry tensile stress. While the coating is harder, it can be more brittle.

Environmental Impact

Modern manufacturing is increasingly conscious of waste. PVD is widely considered a “green” technology. It produces no hazardous chemical waste. CVD, conversely, generates gaseous by-products that must be carefully scrubbed and neutralized before being released, which adds to the facility complexity and environmental footprint.

When to Choose Which: A Selection Framework

Still undecided? Here is how we break it down based on common manufacturing scenarios.

Scenario A: Threading Dies and Taps

You need to coat a tap with deep, fine threads. PVD might struggle to get coating material down into the root of the thread due to line-of-sight issues.

- Winner: CVD (assuming the material is carbide) or specialized rotating PVD for shallower threads.

Scenario B: Finishing End Mills for Aerospace

You are milling Titanium or Inconel and need a sharp edge to prevent work hardening the material. A thick coating would rub rather than cut.

- Winner: PVD. The thin coating maintains the necessary shearing action.

Scenario C: Heavy Turning Inserts

You are turning steel axles all day. The heat generation is massive, and abrasive wear is the primary enemy.

- Winner: CVD. The thick Alpha-Alumina layer usually found in CVD grades provides excellent thermal barriers and wear resistance.

Cost Analysis: Is PVD or CVD More Expensive?

There is no single answer here, as it depends heavily on batch volume.

PVD generally involves higher capital equipment costs and longer cycle times due to the vacuum pump-down and cooling phases. However, because it uses solid targets, the material cost per part can be lower for high-value, small-batch tools.

CVD is often the low-cost winner for massive volume. Because the gas flows everywhere, you can pack a furnace with thousands of carbide inserts at once—stacking them much denser than you could in a PVD chamber (which requires space for rotation). For high-volume insert production, CVD usually offers a lower cost per edge.

Frequently Asked Questions

Which is better, PVD or CVD coating?

Neither is universally “better.” PVD is better for sharp edges, decorative finishes, and temperature-sensitive tools (HSS). CVD is better for heavy wear resistance on carbide inserts and coating complex, internal geometries.

Is PVD coating permanent?

PVD is extremely durable and one of the hardest coatings available, but it is not technically “permanent.” Like any material, it will eventually wear away through friction and abrasion, though it lasts significantly longer than uncoated surfaces.

Can stainless steel be CVD coated?

Generally, no. The high temperatures of CVD (approx $1000^\circ\text{C}$) will anneal most stainless steels, ruining their mechanical properties and corrosion resistance. PVD is the standard choice for coating stainless steel.

Why is PVD often used for decorative hardware?

PVD can be tuned to produce a wide range of uniform colors (Gold, Rose Gold, Black, Blue) without fading or tarnishing. Because it is environmentally friendly and durable, it has replaced traditional electroplating for high-end faucets and door hardware.

Does PVD scratch easily?

No. PVD coatings like Titanium Nitride (TiN) are incredibly hard—often 4x harder than chrome. However, if the underlying material is soft (like brass), a heavy impact can dent the base metal, making it look like the coating failed.

Conclusion

The choice between PVD and CVD is a trade-off between heat, thickness, and geometry.

- Choose PVD if you need to maintain a sharp cutting edge, are working with steel that can’t take high heat, or need a specific decorative finish.

- Choose CVD if you are coating carbide for heavy-duty roughing, or if your part has complex internal recesses that a line-of-sight process can’t reach.

At Accurate Cut, we know that the coating is only as good as the strategy behind it. If you are unsure which process suits your specific project, or if you need advice on material selection for your next run, we are here to help.