Drill Inserts & Coatings Guide: Matching Geometry and Grade for Maximum Tool Life

If you’ve spent enough time on a shop floor, you know the sound. That low-frequency rumble that suddenly shifts into a high-pitched screech. It’s the sound of a drill failing deep inside a part, and it usually means two things: downtime and scrapped material.

In my 15 years working with machining centers and tooling setups, I’ve found that 80% of catastrophic drill failures aren’t caused by the machine or the programming—they’re caused by the wrong insert selection.

Too many machinists treat coatings like a generic upgrade—grabbing the “gold one” (TiN) because it looks familiar. But in modern high-speed machining, chemistry is just as important as geometry. The right coating doesn’t just make the tool look pretty; it acts as a thermal barrier, a lubricant, and a hardness shield all at once.

At Accurate Cut, we focus on precision and durability. This guide breaks down the science of drill inserts and coatings into practical, shop-floor reality so you can stop guessing and start increasing your tool life.

Anatomy of a Drill Insert: It’s Not Just the Gold Layer

Before we talk about the fancy colors on the outside, we have to talk about what’s underneath. A coating is only as good as the substrate it bonds to. You wouldn’t paint a Ferrari engine with house paint, right? The same logic applies here.

The Substrate (The Foundation)

Most high-performance drill inserts use Micro-grain Tungsten Carbide. Here’s the trade-off:

- Hardness: Resists wear but becomes brittle.

- Toughness: Resists chipping but wears out faster.

The “grade” of the insert is the specific recipe of carbide grain size and cobalt binder. If you are drilling interrupted cuts or unstable setups, you need a tougher substrate (higher cobalt). If you are drilling gray cast iron at high speed, you prioritize hardness.

Edge Preparation

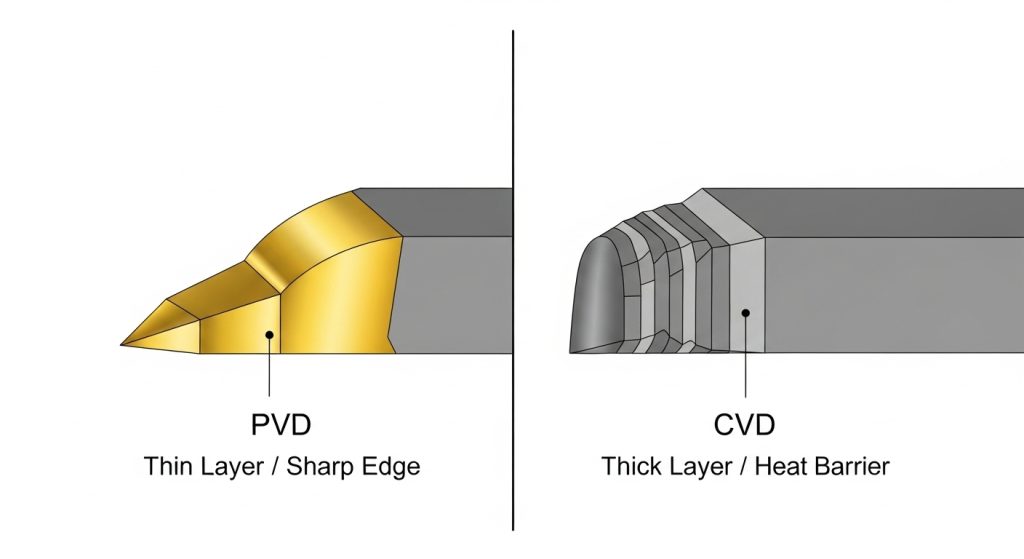

This is where the magic happens. Before an insert is coated, the edge is usually honed (slightly rounded) or chamfered. This honing is critical because coatings—especially CVD types—need a specific surface to adhere to. A “dead sharp” edge often sheds its coating instantly upon entering the cut.

The Chemistry of Performance: PVD vs. CVD

When you look at a catalog, you’ll see these acronyms everywhere. They refer to how the coating is applied to the carbide, and the difference changes the tool’s behavior entirely.

PVD (Physical Vapor Deposition)

Quick Answer: PVD is processed at lower temperatures (~500°C). It creates a thin, smooth layer that hugs the insert’s geometry perfectly.

- Best For: Stainless steel, high-temperature alloys (Inconel/Titanium), and finishing operations.

- Why: Since it’s a thin layer, it allows for a sharper cutting edge. It also puts the surface in compressive stress, which helps prevent cracks from spreading.

CVD (Chemical Vapor Deposition)

Quick Answer: CVD happens at much higher temperatures (~1000°C). It creates a thicker, highly heat-resistant layer.

- Best For: Cast iron and steels running at high speeds.

- Why: The thicker coating acts as a massive thermal barrier, keeping heat out of the carbide substrate. However, because it’s thick, it slightly rounds the cutting edge, making it less ideal for “gummy” materials that need to be sheared.

Common Coatings and Where to Use Them

Let’s move past the acronyms and talk about what you should actually put in the spindle.

TiN (Titanium Nitride) – The Classic Gold

- Color: Gold

- Hardness: ~2300 Vickers (Hv)

- The Verdict: It’s the general-purpose “Toyota Camry” of coatings. It’s decent at everything but master of nothing. It’s great for general steels and identifying wear (since the gold wears off clearly), but it lacks heat resistance for high-speed applications.

TiCN (Titanium Carbonitride) – The Step Up

- Color: Blue-Grey or Pinkish

- Hardness: ~3000 Hv

- The Verdict: Harder than TiN. The addition of Carbon adds hardness and lubricity. This is an excellent choice for abrasive materials like cast iron or silicon-heavy aluminum alloys (if applied correctly).

TiAlN / AlTiN (Titanium Aluminum Nitride) – The Workhorse

- Color: Violet/Black

- Hardness: ~3300+ Hv

- The Verdict: If you are drilling dry or at high speeds, this is your go-to.

- The Science: Here is a fascinating fact—TiAlN actually works better when it gets hot. As the heat rises, the aluminum in the coating reacts with oxygen to form a microscopic layer of Aluminum Oxide (ceramic) on the surface. This creates a heat shield. If you run TiAlN too slow, you aren’t taking advantage of its chemistry.

DLC (Diamond-Like Carbon)

- Color: Black/Rainbow

- Hardness: Extremely High

- The Verdict: The ultimate solution for non-ferrous materials like Aluminum 6061 or Copper. It has an incredibly low coefficient of friction, meaning chips slide right off.

Matching Insert to Material (ISO Application)

This is the section you’ll want to bookmark. In manufacturing, materials are grouped by ISO standards (P, M, K, N, S, H). Here is how to match your grade.

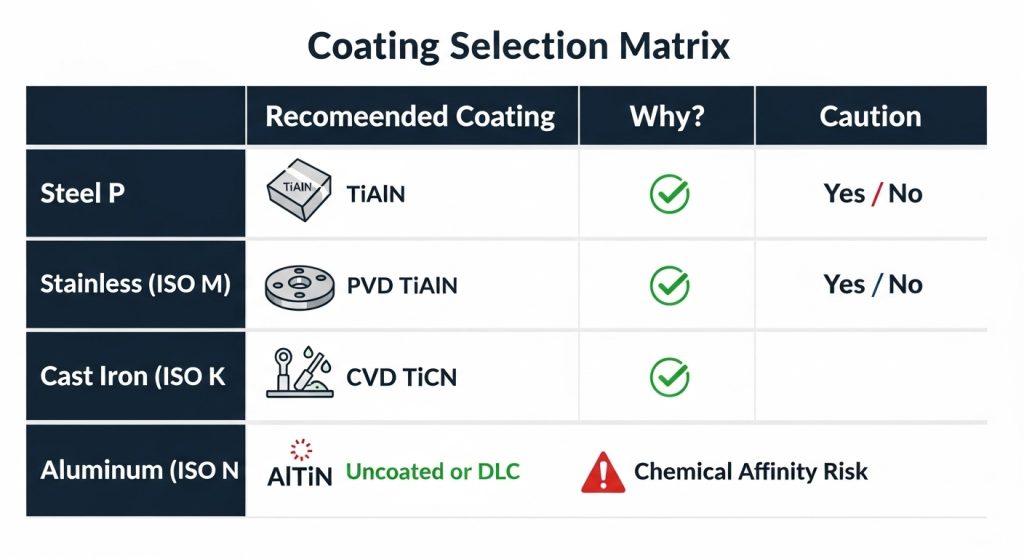

ISO P: Steels (Carbon, Alloy, Tool Steel)

Steel generates heat and creates crater wear.

- Recommendation: Use TiAlN or AlTiN PVD grades.

- Why: You need heat resistance. For softer, gummy low-carbon steels, ensure the edge preparation is sharp to prevent material from tearing.

ISO M: Stainless Steel (304, 316, 17-4)

Stainless is notorious for work hardening (getting harder as you cut it) and being gummy.

- Recommendation: Use a PVD TiAlN or specialized multi-layer PVD coating.

- Critical Tip: You need a sharp edge to shear the material rather than plow it. Avoid thick CVD coatings here; they are too dull and will cause work hardening immediately.

ISO K: Cast Iron (Gray, Ductile)

Cast iron is abrasive. It eats tools like sandpaper.

- Recommendation: CVD TiCN or thick Aluminium Oxide layers.

- Why: You need the thickest, hardest shield possible. The slightly rounded edge of CVD doesn’t hurt you here because cast iron chips break easily.

ISO N: Non-Ferrous (Aluminum, Copper, Brass)

Here is where most competitors make a massive mistake.

- Recommendation: Uncoated (Polished) or DLC.

- The “Sticky” Danger: NEVER use AlTiN or TiAlN on Aluminum. Why? Because Aluminum has a chemical affinity for Aluminum. The chips will chemically weld themselves to the coating (Built-Up Edge), clogging the flutes and snapping the drill.

- Trustworthiness Check: Sometimes, the cheaper, uncoated, highly polished insert is technically superior to the expensive coated one.

Recognizing Failure: Is it the Coating or the Drill?

Troubleshooting is an art form. By looking at a used insert under a loupe, you can determine exactly what went wrong.

- Flank Wear (Even gray wear along the edge): This is normal. If it happens too fast, move to a harder grade (higher wear resistance).

- Crater Wear (Divot on the top face): Caused by heat. The hot chip is eroding the carbide. Switch to a coating with higher oxidation resistance (like AlTiN) or increase coolant flow.

- Built-Up Edge (BUE): Material is welding to the tip. As mentioned above, this is usually a chemical mismatch (using Al-based coating on Al) or cutting speed is too low.

- Chipping: The edge is crumbling. The grade is too hard/brittle, or the coating is too thick (CVD) for the application. Switch to a tougher PVD grade.

ROI Calculation: The Cost Per Hole Mindset

I often see purchasing managers argue over a $2 difference in insert price. This is stepping over dollars to pick up dimes.

Consider this scenario:

- Insert A (Generic TiN): Costs $12. Lasts 200 holes.

- Insert B (High-Performance AlTiN): Costs $18. Lasts 600 holes.

The Math:

- Insert A = $0.06 per hole + 3x machine downtime for tool changes.

- Insert B = $0.03 per hole + 1/3rd the downtime.

The $18 insert is vastly cheaper. When selecting coatings, calculate Cost Per Hole, not cost per box. Strategic selection is the best way to reduce tooling costs with indexable drills.

Conclusion

Choosing the right drill insert coating isn’t about picking the hardest one; it’s about matching the chemical properties of the coating to the mechanical properties of your material.

The Key Takeaways:

- Use PVD for toughness, sharp edges, and stainless steel.

- Use CVD for heat resistance in cast iron and steel.

- AlTiN needs heat to work—don’t baby it.

- Never use aluminum-based coatings on aluminum material.

If you are ready to optimize your production line with tools that actually last, check out the high-performance selection at Accurate Cut. We engineer our grades to handle the reality of modern manufacturing.

Frequently Asked Questions

What is the best coating for drilling stainless steel?

For stainless steel (ISO M), a PVD TiAlN (Titanium Aluminum Nitride) coating is generally the best choice. PVD allows for a sharper cutting edge which is crucial to shear stainless steel and prevent work hardening. Avoid thick CVD coatings as they can be too dull for these gummy materials.

Can I use TiAlN coating on aluminum?

No. You should avoid using TiAlN or AlTiN on aluminum. Since the coating contains aluminum, it has a chemical affinity to the material, causing the aluminum chips to weld to the tool (Built-Up Edge). For aluminum, use DLC (Diamond-Like Carbon) or a polished uncoated carbide insert.

Does coating thickness matter?

Yes. Thicker coatings (like CVD) provide better heat insulation and wear resistance for abrasive materials like cast iron. Thinner coatings (PVD) offer better adhesion and edge sharpness, which is vital for superalloys and stainless steel.

What is the difference between drilling inserts and solid carbide drills?

Solid carbide drills are made from a single piece of carbide, offering high rigidity and precision for smaller diameters. Drilling inserts (check out our indexable drilling guide) consist of a steel body with replaceable carbide tips. One of the major advantages of replaceable inserts is that they are more cost-effective for larger holes because you only replace the worn tip, not the entire tool.

How do I know when to index or change my drill insert?

Listen to your machine. A change in sound (screeching or heavy rumbling) indicates dullness. Visually, look for flank wear exceeding 0.2mm-0.3mm. If you see chipping or inconsistent power load on the spindle monitor, change the insert immediately to save the drill body.