How Insert Coating Impacts Tool Life

The sound of a cutting tool failing mid-pass is distinctive—and expensive. It is the sound of downtime, scrapped parts, and profit evaporating from the shop floor. In precision manufacturing, the difference between a profitable run and a logistical headache often comes down to a layer of material thinner than a human hair: the insert coating.

While the carbide substrate provides the toughness required to withstand the cutting force, the coating handles the heat, chemical interaction, and abrasive wear. Whether you are using standard turning tools or specialized drill inserts, we view coatings not just as an accessory, but as a fundamental component of tool geometry and performance.

Understanding the mechanics behind these coatings allows manufacturers to push surface footage, improve tolerance consistency, and significantly extend tool life. This guide breaks down exactly how insert coatings function, the critical difference between PVD and CVD application methods, and how to select the right chemistry to maximize your return on investment.

The Mechanics of Protection: Why Coat an Insert?

To understand how coating impacts tool life, we must look at the microscopic interactions occurring at the cutting interface. When a tool shears metal, it generates immense heat and pressure. Uncoated carbide, while hard, has a relatively high coefficient of friction and can be chemically reactive with certain workpiece materials, leading to rapid cratering or flank wear.

Coatings function through a “triad of protection” that directly influences longevity:

1. Surface Hardness

Coatings like Titanium Carbonitride (TiCN) are significantly harder than the tungsten carbide substrate. This extreme surface hardness provides a barrier against abrasive wear, particularly when machining abrasive materials like cast iron or high-silicon aluminum.

2. Thermal Stability

Heat is the enemy of tool life. As cutting temperatures rise, the carbide binder (typically cobalt) can soften, leading to plastic deformation of the cutting edge. Coatings act as a thermal insulator. By directing heat into the chip rather than the tool, the substrate remains cooler, maintaining its structural integrity even during high-speed machining operations.

3. Lubricity (Reduced Friction)

Perhaps the most underrated factor is lubricity. Uncoated carbide has a coefficient of friction around 0.5 against steel. Advanced coatings can lower this to 0.3 or less. Reduced friction means less heat generation and smoother chip evacuation. This is critical for preventing Built-Up Edge (BUE), where workpiece material welds itself to the insert, altering the geometry and leading to catastrophic failure.

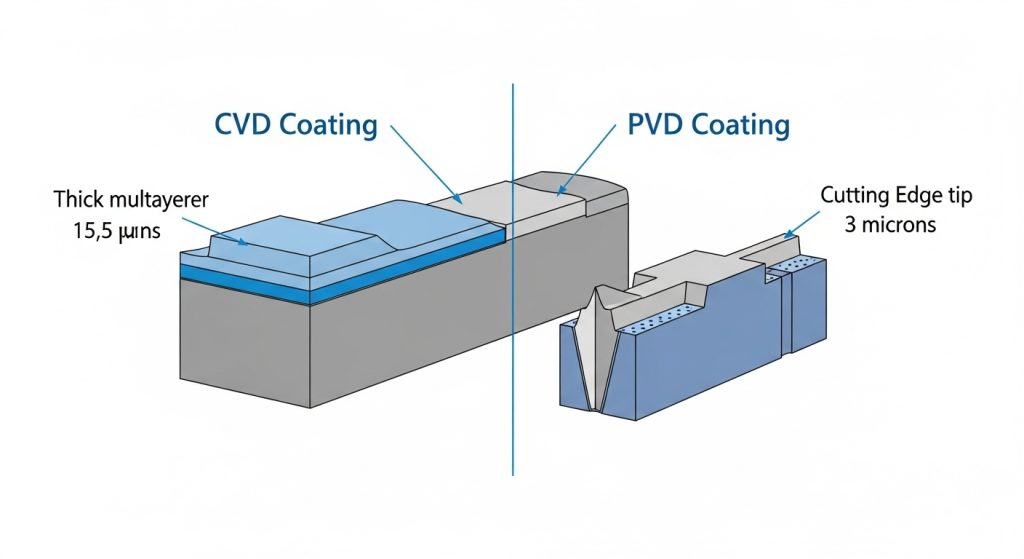

CVD vs. PVD: The Application Method Matters

Before selecting a specific coating chemistry (like TiN or AlTiN), it is vital to understand the application method. The way the coating is applied fundamentally changes the characteristics of the cutting edge.

CVD (Chemical Vapor Deposition)

CVD coatings are applied at high temperatures (around 1000°C) through chemical reactions in a gas atmosphere.

- Thickness: Thicker layers (5–20 microns).

- Characteristics: Excellent heat resistance and adhesion. Ideal for turning applications where heat generation is the primary failure mode, such as when you need the best drill insert for steel in high-speed setups.

- The Trade-off: Since it is a thick layer, it tends to slightly round the cutting edge. It also leaves the coating in a state of tensile stress, making it slightly more prone to micro-cracking in interrupted cuts.

PVD (Physical Vapor Deposition)

PVD coatings are applied at lower temperatures (around 500°C). This process involves vaporizing a solid metal and condensing it onto the insert.

- Thickness: Thinner layers (2–5 microns).

- Characteristics: Can be applied to very sharp edges without dulling them. PVD coatings possess compressive stress, which adds toughness.

- Best Use: Milling, threading, and finishing operations where a sharp edge and resistance to chipping (interrupted cuts) are required.

The Bottom Line: If you are rough turning steel and generating massive heat, CVD is likely your best option. If you are milling stainless steel or finishing a part that requires a razor-sharp edge, PVD is the superior choice.

Common Coating Types and Material Match-ups

The color of an insert—gold, black, grey, or silver—is dictated by the coating chemistry. While easy to identify by sight, the chemical properties are what determine tool life in specific materials. (For a deep dive into hole-making specifics, see our drill insert coatings guide).

TiN (Titanium Nitride) – The Gold Standard

Recognizable by its bright gold color, TiN was the first major PVD coating. It is a general-purpose coating that works well on a wide variety of materials.

- Why use it: It provides a good balance of hardness and toughness. The gold color also makes it very easy to spot wear, helping operators identify when to index the tool.

- Limitation: It has lower heat resistance compared to modern alternatives.

TiCN (Titanium Carbonitride) – The Hardness Upgrade

By adding carbon to the TiN lattice, manufacturers create a coating that is harder and more wear-resistant. It typically appears grey or bronze.

- Why use it: Excellent for interrupted cuts or operations requiring high feed rates. It is often the go-to for milling stainless steels (see our guide on the best drill insert for stainless steel for more details) or difficult-to-machine alloys.

AlTiN / TiAlN (Aluminum Titanium Nitride) – The Heat Lover

Usually violet-black or dark grey, this is a high-performance coating. Interestingly, AlTiN functions best when it gets hot. The heat from machining causes the aluminum in the coating to form a thin, protective layer of aluminum oxide on the surface.

- Why use it: Essential for dry machining (no coolant) and High-Speed Machining (HSM). It allows for significantly higher surface footage (SFM) than TiN or TiCN.

Diamond / DLC (Diamond-Like Carbon)

For non-ferrous materials, diamond coatings are the pinnacle of wear resistance.

- Why use it: When machining high-silicon aluminum (which is incredibly abrasive), graphite, or composites, DLC prevents the material from sticking to the tool and resists abrasion.

- Warning: Never use diamond coatings on ferrous metals (steel/iron). The chemical affinity between carbon and iron at high temperatures will cause the coating to dissolve rapidly.

Quantifying the Impact: Speed, Feed, and ROI

The primary goal of using a coated insert is not just to make the tool last longer—it is to make the process faster. Tool life should be viewed as a function of productivity.

If a standard uncoated insert lasts 20 minutes at 400 SFM, and a premium AlTiN coated insert lasts 15 minutes at 800 SFM, the coated insert is often the better financial choice despite the shorter absolute life. Why? Because it doubled your production rate.

ROI Factors to Consider:

- Machine Rate: If your machine burden rate is $100/hour, saving 10 minutes of cycle time is worth $16.60 per part.

- Downtime: Every time an operator stops to index an insert, you lose 5–10 minutes of production. Coatings that predictively extend life reduce these interruptions.

- Scrap Rate: As tools wear, dimensions drift. Coated inserts maintain their dimension longer, ensuring process capability (Cpk) remains high.

In our experience at Accurate Cut, switching from a general-purpose TiN coating to a material-specific AlTiN coating for hardened steel applications often yields a 50% to 100% increase in tool life, or allows for a 20% increase in cutting speeds with no penalty to longevity.

Troubleshooting: Reading Your Coated Insert Wear

The state of the coating on a used insert tells a story. Learning to read these signs can help you optimize your tooling selection.

Delamination (Flaking)

If the coating is peeling off like old paint, it indicates an adhesion failure.

- Cause: This can happen if a CVD coating is used in an application with too much mechanical shock, or if the coolant causes thermal shock.

- Fix: Switch to a tougher PVD grade or ensure continuous coolant flow (or run dry).

Built-Up Edge (BUE)

If you see workpiece material welded onto the cutting edge, the coating lacks sufficient lubricity or the cutting speed is too low.

- Impact: BUE effectively changes the tool geometry, leading to poor surface finish and eventual edge chipping.

- Fix: Increase cutting speed (to generate enough heat to plasticize the chip) or switch to a coating with a lower coefficient of friction, such as TiCN.

Rapid Crater Wear

If a depression forms on the top (rake) face of the insert shortly after starting the cut, the heat is penetrating the coating too easily.

- Fix: Use a thicker CVD coating with an aluminum oxide layer to better insulate the substrate from heat.

When NOT to Use a Coated Insert

While coatings are beneficial for 90% of applications, there are specific scenarios where uncoated carbide is superior.

- Aluminum Finishing: While coatings exist for aluminum, many machinists prefer uncoated, highly polished carbide for finishing passes. The coating process (especially CVD) can slightly round the cutting edge. Aluminum requires a razor-sharp edge to shear cleanly; a duller coated edge can “plow” the material, causing a cloudy finish.

- Plastics: Similar to aluminum, soft plastics require extreme sharpness to prevent melting or deformation.

- Titanium (Specific Alloys): In some low-speed titanium operations, certain coatings can react chemically with the material. Uncoated grades or specific specialized coatings are often preferred here.

Conclusion

Insert coatings are a critical variable in the manufacturing equation. They provide the thermal barrier, surface hardness, and lubricity required to turn raw stock into precision components efficiently. However, a “more expensive” coating does not automatically mean “better” if it is mismatched to the application.

To maximize tool life, you must align the coating properties (PVD vs. CVD, chemistry) with your specific workpiece material and machining environment. Whether you are running a lathe or trying to choose the right drill insert grade, matching the tool to the task is the secret to success.

When done correctly, the result is a stable process, reduced machine downtime, and lower cost per part. For expert guidance on selecting the right tooling and optimizing your production lines, the team at Accurate Cut is ready to assist.

Frequently Asked Questions

Does coating thickness affect tolerance holding?

Yes, slightly. CVD coatings can be 10-20 microns thick, which significantly adds to the dimension of the insert. However, precision inserts are ground before coating to account for this, or the tolerance class of the insert allows for this variation. For ultra-precision micron-level tolerances, PVD (thinner) or uncoated tools are often easier to manage.

Can you regrind and recoat carbide inserts?

Generally, no. While solid carbide end mills and drills are frequently reground and recoated, indexable inserts are designed as consumables. The cost to grind and recoat a standard insert usually exceeds the cost of buying a new one, and the geometry would be altered beyond specification.

Why are some inserts black and others gold?

The color is a result of the chemical composition of the coating. Titanium Nitride (TiN) is naturally gold. Titanium Carbonitride (TiCN) ranges from grey to bronze. Aluminum Titanium Nitride (AlTiN) is typically violet-black. However, some manufacturers add a purely cosmetic “flash” layer on top to make wear detection easier (e.g., a gold top layer on a black coating).

Is PVD or CVD better for stainless steel?

For milling stainless steel, PVD is almost always the better choice due to its ability to maintain a sharp edge and resist the thermal cracking caused by interrupted cuts. For continuous turning of stainless steel where heat generation is high, a CVD grade may be preferred to block the heat.

What is the heat limit for AlTiN coatings?

AlTiN coatings generally have an oxidation resistance of up to 800°C – 900°C. This is significantly higher than TiN (approx. 600°C). This high thermal threshold is why AlTiN is the industry standard for dry machining and cutting hardened steels.