How to Extend Indexable Drill Tool Life

Maximize your drilling ROI. Accurate Cut reveals 5 engineering strategies to extend indexable drill tool life, from pocket maintenance to coolant optimization.

Tool life isn’t just about saving $15 on an insert; it’s about process security, machine uptime, and the confidence that your lights-out cycle won’t end in a crash.

In many manufacturing environments, the goal is often “maximum minutes in the cut.” However, at Accurate Cut, we teach a different philosophy: predictable consistency. Pushing a tool to its absolute breaking point is a gamble that eventually costs more in scrapped parts and damaged drill bodies than the value of the remaining carbide.

We have analyzed thousands of drilling cycles and found that tool life is rarely limited by the quality of the carbide itself, but by the systemic factors surrounding it—heat, vibration, and chemical wear. By managing these variables, you can extend the reliable life of your indexable drills significantly.

The Foundation: Drill Body Health

You cannot get extended life from a new insert if it is clamped into an old, fatigued drill body. The drill body is the foundation of the cut; if it is compromised, the insert will fail prematurely regardless of your cutting parameters.

The “Disposable” Reality

It is important to recognize that indexable drill bodies are consumables, not permanent fixtures. Every time an insert cuts, cutting forces try to push it out of the pocket. Over thousands of cycles, the steel pocket plastically deforms.

Inspection Protocol

Before blaming the insert grade or coating, inspect the pocket:

- Gap Check: Place a new insert in the seat. If you can fit a 0.001″ shim between the insert and the wall, the body is washed out.

- Fretting Corrosion: Look for dark rubbing marks on the back of the pocket. This indicates the insert is micro-moving during the cut, leading to chipping and inconsistent wear.

For a comprehensive guide on when to retire your tool bodies, refer to our industrial drill maintenance and buying guide.

The Speed vs. Feed Balance

One of the most common mistakes we see is operators slowing down the feed rate to “save the tool.” In reality, feeding too lightly often kills the tool faster.

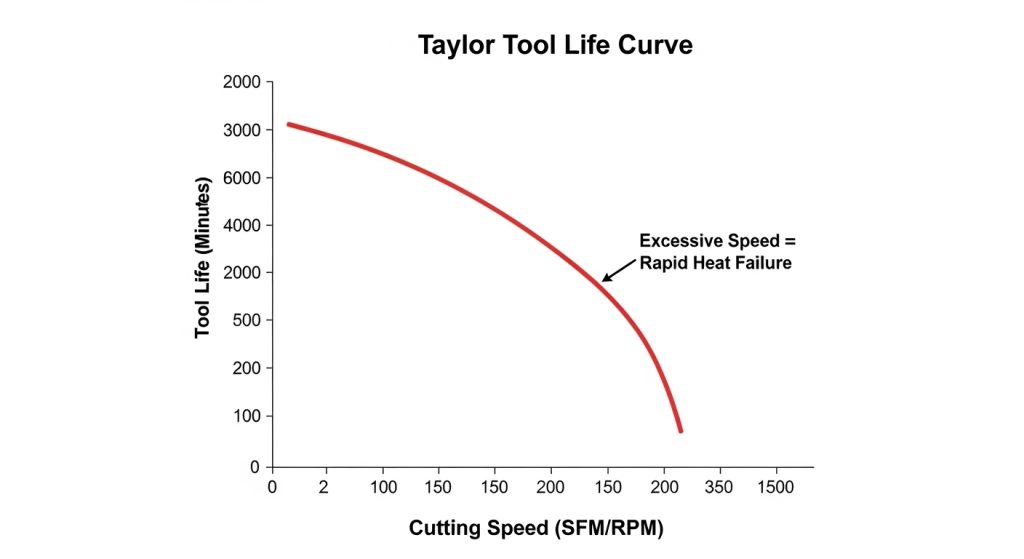

This dynamic is governed by the Taylor Tool Life Equation, but the practical application is simple:

- Cutting Speed (RPM) generates Heat. Heat degrades the binder in the carbide (cobalt), leading to rapid crater wear.

- Feed Rate (IPR) generates Mechanical Load. This causes physical wear but is far less damaging to the chemical structure of the carbide.

The Heat-in-the-Chip Principle

To extend tool life, you want to get the heat out of the tool and into the chip.

- Low Feed: The tool rubs, generating friction heat that soaks into the insert.

- High Feed: The tool shears the metal efficiently, and the hot chip carries the heat away from the cutting edge.

Our Engineering Recommendation: To maximize life, run the lowest recommended surface footage (SFM) and the highest recommended feed rate (IPR) that your surface finish requirements allow.

Coolant Concentration (The 10% Rule)

Most shops understand that drilling requires coolant pressure to evacuate chips. However, few pay enough attention to coolant concentration.

Indexable drilling is a high-friction operation. The coolant must provide lubricity to prevent the material from welding to the cutting edge (Built-Up Edge).

The Refractometer Test

Water is a great coolant but a terrible lubricant.

- At 4-6% Concentration: You are essentially running water. This leads to thermal shock and built-up edge, especially in stainless steel and aluminum.

- At 8-12% Concentration: You create a robust chemical barrier between the tool and the workpiece.

Increasing your coolant concentration to 10% (Brix) is often the single most effective way to stop premature wear and extend tool life by 20-30%.

Minimizing Entrance and Exit Shock

Analysis of failed tools shows that nearly 80% of insert damage occurs during the first or last millimeter of the cut. These are the moments of highest instability.

The “Soft Entry” Technique

When the drill first touches the material, it acts like a hammer. To mitigate this shock:

- Reduce the feed rate by 50% for the first 0.100″ (2.5mm) of the cut.

- Once the drill is fully engaged and stabilized by the guide pads, ramp up to 100% feed.

The Exit Lunge

As the drill breaks through the bottom of the part, the resistance drops to zero. If your machine’s spindle bearings or ballscrews have any play (backlash), the drill can “lunge” forward, snapping the insert. Reducing feed at the exit protects the edge from this breakout force.

If you are seeing catastrophic breakage at these points rather than normal wear, read our analysis on why drill inserts break.

Tracking “Load” Instead of “Time”

Traditionally, shops track tool life by “minutes in the cut” or “number of holes.” While useful, this is a trailing indicator. A smarter approach for modern CNCs is Load Monitoring.

The Baseline Method

- Establish a Baseline: Run a brand-new tool and record the spindle load percentage (e.g., 45% load).

- Set a Limit: Tool wear increases cutting forces linearly. Set a tool life limit at a 15-20% increase in load (e.g., when it hits 55% load).

By changing the tool based on load rather than an arbitrary number of holes, you ensure you are getting the maximum safe life out of every edge without risking a failure.

When to Rotate: Understanding Wear Limits

How do you know the tool is truly “done”?

You should not wait for the edge to chip. If you are struggling with micro-fractures on the cutting edge before the tool is worn, we recommend reviewing our guide on how to prevent chipping in drill inserts.

To maximize consistent tool life, you should look for Flank Wear.

- The Limit: We recommend rotating the insert when you see a wear land (smooth shiny strip on the edge) of 0.2mm to 0.3mm.

- The Risk: Once wear exceeds 0.3mm, cutting forces skyrocket, and the risk of fracturing the insert—and destroying the drill body—increases exponentially.

Conclusion

Extending tool life is an active process of monitoring and adjusting. It requires shifting the focus from “how fast can we go” to “how stable can we make it.”

By protecting the drill body, managing heat through proper coolant concentration, and trusting the physics of high-feed shearing, you can turn your drilling operations into a predictable, high-ROI process.

At Accurate Cut, we engineer our inserts to deliver consistent performance in the toughest materials. Contact our technical team to audit your current parameters and discover where you can unlock hidden tool life.

Frequently Asked Questions

How many holes should an indexable drill last?

There is no single number. In mild steel (1018), a drill might last 2,000 inches. In Inconel, it might last 20 inches. The key is to establish a baseline for your specific application and consistency.

Does coating color matter for tool life?

The color helps identify the coating type, which dictates tool life. Gold (TiN) is a general-purpose coating. Grey/Black (TiAlN/AlTiN) indicates high heat resistance, essential for harder steels and high-speed running. Matching the coating to the material is critical for longevity.

Can I rotate the inserts to different pockets?

Generally, no. In most modern high-performance drills, the center insert and peripheral insert have different geometries and grades. The center needs toughness; the periphery needs wear resistance. Swapping them usually leads to immediate failure.

Why does my drill squeal?

A high-pitched squeal is usually a sign of rubbing. This means your feed rate is too low or the speed is too high. Increase the feed rate to stabilize the cut and stop the harmonics; this will often extend the life of the tool by reducing friction heat.