How to Fix Chip Packing During Drilling

Is chip packing causing tool breakage? Learn to optimize coolant pressure, adjust feed rates for chip breaking, and prevent flute clogging. Expert guide.

Chip packing is a silent killer in deep-hole drilling. Unlike chatter, which you can hear immediately, packing often happens silently inside the hole until the moment of failure. You might see a spike in the spindle load meter, hear a sudden “crunch,” and then the tool snaps.

The fundamental problem is one of physics: Chip Volume Expansion. When you machine metal, the resulting chips occupy significantly more volume than the solid material they came from—often 2 to 3 times the space.

If these expanded chips cannot exit the hole faster than they are generated, they compress into a solid plug. This leads to “Chip Recutting,” where the drill is forced to cut through hardened steel chips and the workpiece simultaneously. The result is catastrophic failure.

At Accurate Cut, we approach chip packing as a failure of evacuation dynamics. By adjusting your parameters to change the shape of the chip and the force of the coolant, you can eliminate packing risks.

The Root Cause: Chip Shape vs. Flute Geometry

The first step in fixing packing is to look at the chips you are producing. The flute of the drill is a conveyor belt with limited capacity. If the chip is too long or too wide, it jams the conveyor.

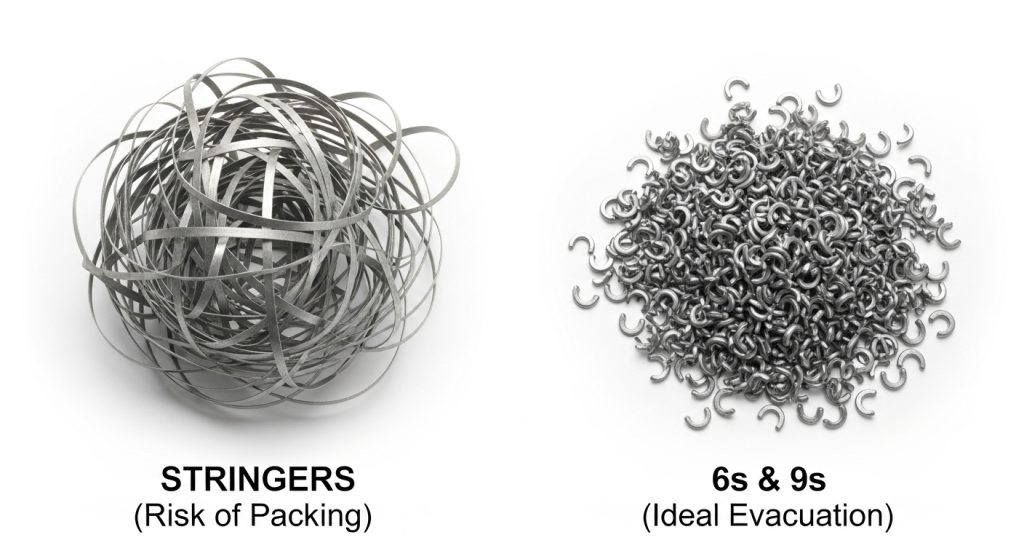

The “6 and 9” Rule

- Ideal Chips: Look like the numbers “6” or “9.” They are small, tight curls that flow easily up the flute.

- The Enemy (Stringers): Long, continuous ribbons of metal. These wrap around the tool (bird-nesting) and clog the flutes instantly.

Diagnosis: If you see a “bird nest” of stringy chips wrapped around the tool holder or the shank, you have a packing problem waiting to happen. It means the chips are not ejecting; they are tangling.

The Feed Rate Paradox (Break the Chip)

When operators hear the drill struggling, their instinct is often to slow down the feed rate. This is usually the wrong move.

The Physics of Chip Breaking

- Low Feed Rate: Produces thin, flexible chips. These chips do not break; they bend and flow as long stringers, which leads to packing.

- High Feed Rate: Produces thick, rigid chips. Because the chip is thicker, it cannot bend as easily. When it hits the chip breaker geometry on the insert, it snaps into small, manageable pieces.

The Fix: If you are producing stringers, increase your feed rate (IPR). You need to push the tool hard enough to snap the chip.

If increasing the feed leads to edge failure, you may need to investigate other causes of breakage. Read our guide on why drill inserts break to find the balance between chip breaking and insert strength.

Fluid Dynamics (Pressure > Volume)

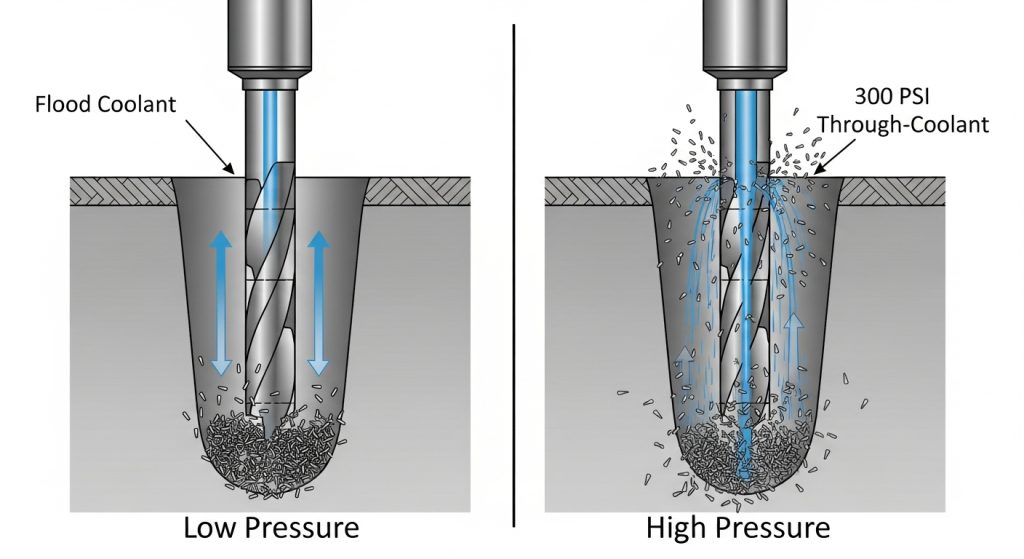

In deep-hole drilling (3xD and deeper), flood coolant is rarely sufficient. Gravity and centrifugal force work against the coolant entering the hole.

The Pressure Requirement

To flush chips out of a deep vertical hole, you need kinetic energy.

- Flood Coolant: Good for cooling, bad for evacuation.

- Through-Spindle Coolant (TSC): Essential for indexable drilling.

- The Standard: We recommend a minimum of 300 PSI for effective evacuation.

If the chips are packing at the bottom of the hole, they will grind against the side walls as they are forced up, ruining the hole quality. See our guide on how to diagnose poor hole surface finish to identify these specific “scoring” marks.

Pecking vs. Chip Breaking Cycles

Standard High-Speed Steel (HSS) drills rely on “Peck Drilling” (G83 – Full Retract) to clear chips. However, for Carbide Indexable Drills, full retraction is dangerous.

The Danger of Full Retraction

- Thermal Shock: The carbide heats up in the cut and is blasted by coolant when it retracts, causing micro-cracking.

- Chip Ingestion: When the drill fully retracts, loose chips can fall to the bottom of the hole. When the drill rapids back in, it crushes these chips, leading to chipping. Learn more about this in our article on how to prevent chipping in drill inserts.

The Alternative: Chip Breaking Cycle

Instead of a full retract, use a Chip Break Cycle (G73). The drill retracts only a small amount (e.g., 0.010″ – 0.020″) or simply pauses for a fraction of a second. This momentary break snaps the stringer chip without removing the tool from the hole, maintaining coolant pressure and preventing chip ingestion.

Tool Design Factors

If you have optimized feed and coolant but still suffer from packing, the issue may be the drill body itself.

- Polished Flutes: High-performance drills feature polished flutes to reduce the coefficient of friction, allowing chips to slide out more easily.

- Helix Angle: For gummy materials like aluminum or stainless, a higher helix angle helps “lift” the chips out of the hole.

Also, check your drill body for damage. If the flutes are scarred or worn from previous failures, chips will snag on the rough spots. Refer to our industrial drill maintenance and buying guide for inspection tips.

Conclusion

Chip packing is a failure of evacuation. It means the volume of material being removed exceeds the capacity of the flutes to eject it. By trusting the physics—increasing feed to break chips and increasing pressure to flush them—you can keep the hole clear.

At Accurate Cut, we design our insert geometries specifically to promote chip curling and breakage. If you are struggling with clogged tools, stop pecking and start breaking chips.

Frequently Asked Questions

How do I know if chips are packing?

The most obvious sign is a fluctuating or spiking Spindle Load Meter. If the load gradually climbs higher as the drill goes deeper, friction is building up due to packing. You may also hear a distinct “crunching” or “grinding” sound, which is the sound of chips being recut.

Should I use oil or water-soluble coolant?

For chip evacuation, Oil is superior because it provides higher lubricity, helping chips slide up the flute with less friction. However, water-soluble coolant handles heat better. If packing is your main issue, increasing the concentration of your water-soluble coolant (to 10-12%) can help mimic the lubricity of oil. This also helps with how to extend indexable drill tool life.

Why do chips pack more in aluminum?

Aluminum is soft and “gummy.” It doesn’t break naturally like steel; it tends to flow into long ribbons. Furthermore, aluminum expands significantly when cut. For aluminum, sharp, high-positive rake inserts and extremely high coolant volume are required to force the material out.