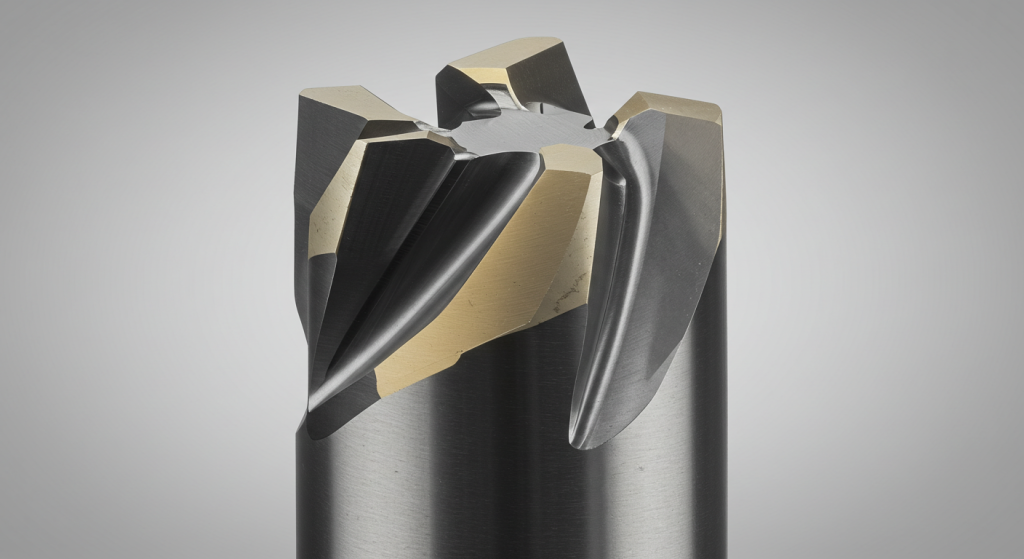

Indexable Drill Insert – High-Precision Carbide Inserts

What is an Indexable Drill Insert?

An indexable drill insert is a cutting tool characterized by an exchangeable cutting edge. This design enables machinists to exchange damaged or worn cutting inserts and does not require the replacement of the entire drill. This design is easily formed into modules, which is why they are very cost-effective relative to solid carbide drills. These inserts are commonly made out of high-quality carbide, offering:

- Clean cutters to drill to the point.

- Outstanding hardness to provide long service.

- Better industrial wear resistance.

With these tools, manufacturers can attain uniform hole quality, less vibration, and enhanced overall machining time.

Indexable Drill Insert: Accuracy, Endurance, and Performance Machining

Efficiency, precision, and durability are the most important when it comes to industrial drilling. This is why the indexable drill insert has become a staple in contemporary machining, providing high-performance results in a broad material and application area. These replaceable drill inserts can be used in CNC machining up to heavy-duty industrial applications with a cutting-edge design and a rugged material to keep them highly productive and with minimal downtime.

Major Characteristics of Indexable Drill Inserts

- Replacement Cutting Inserts

Interchangeable cutting inserts are one of the main benefits of the indexable drills. These inserts can be changed one at a time, unlike solid carbide drills, which need to be replaced when worn out, resulting in less material cost and less downtime. This is a particularly desirable feature in industrial high-volume applications where the life of the tools is critical.

- Multi-Functional Performance

Indexable drills can drill a hole that can be small, precise, or large in diameter, and can be used in a variety of materials, including metals, plastics, and composite materials. The multi-functional ability helps to ensure that machinists can count on the same tool to work on multiple projects, enhancing workflow efficiency.

- Modular Design

A lot of indexable inserts are designed with a modular design, so the tool can be customized to fit a particular need. Users can select:

- Shank type

- Coolant delivery method

- Drill body length

The flexibility enables the optimization of performance depending on the machining operation.

- High Accuracy

Industries such as aerospace, automotive, and metalworking require precision drilling. Drill inserts are indexable and engineered to provide high accuracy and tight tolerances, so the hole size, finishes, and angles are all precisely accurate.

- Coolant Delivery System

A coolant delivery system is often built into modern indexable drills, and the system lowers heat and friction when drilling. This extends the life of the tool, provides greater chip removal, and reliable performance at high speeds.

- Reduced Downtime

The inserts can be changed one at a time, and the drills are extremely robust, so indexable drills usually require less time for stoppage than solid carbide drills. This results in increased productivity, decreased maintenance, and greater efficiency.

High Precision Drill Insert SP 3XD

One of the more recent developments in indexable drill insert is the SP 3XD high precision drill insert. This insert is designed to work in harsh machining conditions and has several benefits:

- Constructed using high-quality carbide material, with sharp edges, high hardness, and high wear ability.

- The design of 3XD geometry encourages stable evacuated chips and uniform hole quality.

- Cuts tools more easily, extends life, and allows hassle-free high-speed machining.

- Works best on steel, stainless steel, and cast iron.

- Useful where accurate performance and right hole finishing are of importance.

The SP 3XD insert is an example of how new generation indexable drill insert are designed to suit the changing needs of industrial machining.

Indexable Drill Inserts Applications

Indexable drilling inserts are very versatile and can be used in a wide variety of industries and materials:

- CNC Machining: Drill inserts with a long life have the advantage of high-speed operation.

- Industrial Production: Steel indexable inserts are heavy-duty and offer high production volume.

- Aerospace and Automotive Applications: Indexable inserts are used to achieve tight tolerances and a high-standard finish in aerospace and automotive applications.

- Metalworking: Metalworking drill inserts are best used on steel, stainless steel, aluminum, and other alloys.

- Precision Machining: Metal indexable inserts offer precise hole sizes and a minimum of burrs.

By choosing an appropriate high-performance carbide indexable insert, machinists can optimize the efficiency and deliver the same performance on a wide range of materials.

Benefits of Solid Carbide Drills

Drill inserts have several advantages over customary solid carbide drills:

- Cost-Effectiveness: The cutting insert is the only part that is required to be changed, cutting down the costs of tooling.

- Great Wear Life: The carbide inserts have high wear resistance and long life.

- Flexibility: Modular construction can be adapted to other applications and materials.

- Precision: Has close tolerances and finishes of holes.

- Less Heat and Vibrations: In-built coolant systems and superior geometries provide smoother operations.

These benefits render indexable inserts invaluable in current machining and CNC processes.

Technical Considerations

Indexable inserts are based on several engineering concepts to maximize performance:

- Geometry Design: Designs such as 3XD geometry enhance geometry flow and decrease torque.

- Coating Technology: Coatings made of Titanium Nitride (TiN) or other elements provide wear resistance and lessen friction.

- Insert Grade: The grade of carbide differs to offer toughness and hardness according to the use.

- Chip Evacuation: Designing the flutes correctly eliminates clogging and heat accumulation.

Conclusion

Indexable inserts are an essential part of present-day machining with economical cost, high accuracy, and industrial performance. Modular designs, advanced geometries, and replaceable inserts allow manufacturers to obtain reduced downtime, enhanced productivity, and excellent hole quality. Professional-grade indexable drill insert can be found at AccurateCut to view our full line of CNC drill inserts, metalworking cutting tools, and precision drill inserts.