What Makes Indexable Drills Efficient in CNC

If you’ve spent enough time on a shop floor, you know the sound of a bottleneck. It’s usually the rhythmic, agonizing peck-peck-peck of a High-Speed Steel (HSS) twist drill trying to punch a 2-inch hole through 4140 steel.

In the world of production machining, hole-making often accounts for the largest percentage of machining time. Yet, many shops still treat drilling as an afterthought, focusing their optimization efforts on milling or turning paths. This is a mistake.

At Accurate Cut, we’ve seen firsthand that switching from traditional twist drills or even solid carbide to high-performance indexable drills (often called U-drills) can revolutionize a production run. But efficiency isn’t just about running higher Surface Feet Per Minute (SFM). It’s a combination of mechanics, inventory management, and versatility.

Here is exactly why indexable drills are the most efficient tools in your CNC arsenal for holes larger than 0.75 inches.

The Bottom Line: Why Make the Switch?

Quick Answer: Indexable drills are efficient because they utilize carbide inserts capable of running at 3-4x the speed of HSS, eliminate the need for pilot holes and pecking cycles, and allow for “zero-change” cutting edge renewal. They reduce the Cost Per Hole by maximizing machine uptime and minimizing tool management overhead.

The Mechanics of Speed: Eliminating the Peck Cycle

The most obvious efficiency gain is raw speed, but the reason for that speed is often misunderstood. It comes down to the physics of how the tool enters the material.

Unlike a solid drill which has a chisel edge at the center that effectively “extrudes” material before cutting, an indexable drill uses a two-insert system: a central insert and a peripheral insert.

- The Central Insert: Handles the low surface speed at the center of the rotation.

- The Peripheral Insert: Handles the high surface speed at the outer diameter.

The “No Pecking” Rule

The single biggest time-saver isn’t just the cutting speed—it’s the toolpath.

With traditional drilling, especially deep holes, you are forced to use a Peck Drilling Cycle (G83) to break chips and clear flutes. Every time that tool retracts, your Material Removal Rate (MRR) drops to zero.

Indexable drills are designed to run with high-pressure through-spindle coolant. The coolant blasts chips out of the hole immediately. This allows you to use a direct plunge feed (G81 or G01). You enter the cut and don’t stop until you reach the bottom.

Pro Tip: In our experience, eliminating the peck cycle alone can reduce cycle time by 50% to 70% on holes deeper than 3x Diameter.

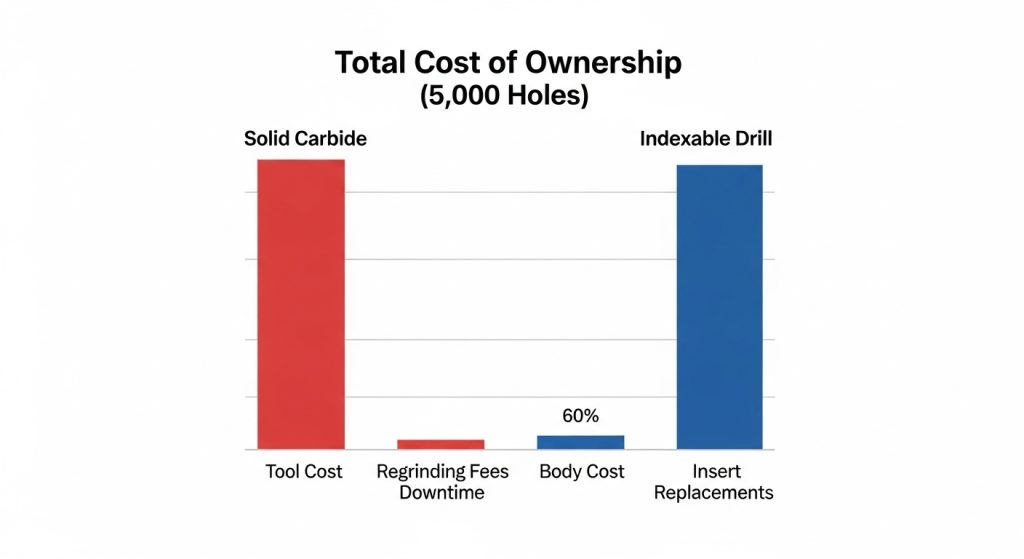

Economic Efficiency: The Cost-Per-Hole Equation

When managers look at tooling costs, they often stare at the sticker price. Yes, an indexable drill body is an investment, and boxes of inserts aren’t cheap. However, the “sticker price” is a vanity metric. The real metric that matters is Cost Per Hole.

The Hidden Cost of Regrinds

Solid carbide drills are fantastic tools, but they come with administrative baggage. When a solid carbide drill dulls, the process looks like this:

- Pull tool from machine.

- Put in “Regrind Bin.”

- Ship to grinding house.

- Wait 2 weeks.

- Receive tool, update offsets (because the length changed), and re-measure.

That is a logistical nightmare. With an indexable drill, when an edge dulls, the operator simply rotates the insert. It takes 45 seconds at the machine. No offset changes (usually), no shipping, no waiting.

Inventory Management

From an inventory standpoint, you are storing tiny boxes of inserts rather than racks of expensive carbide rods. This frees up cash flow—money that isn’t sitting in a tool crib drawer gathering dust.

Versatility: Doing More Than Just Drilling

This is where the “pros” separate themselves from the amateurs. An indexable drill isn’t just a drill; if you are running it on a CNC lathe, it is also a boring bar and a turning tool.

1. X-Axis Offsetting

Here is a scenario we see constantly: You need to drill a 1.000″ hole, but you only have a 0.984″ (25mm) drill.

With a solid drill, you are stuck. You have to drill and then bore. With an indexable drill on a lathe, you can simply offset the tool in the X-axis. Because of the flat bottom design and the peripheral insert, you can “push” the drill to cut a slightly larger diameter than the tool itself.

- Static Setup: Drills the nominal diameter.

- Offset Setup: Can open the hole up by 0.010″ – 0.020″ (depending on manufacturer specs).

This capability allows you to dial in a tolerance without changing tools, saving a massive amount of tool changer positions and setup time.

2. Rough Boring and Chamfering

Once the drill reaches the bottom of the hole, you don’t always have to retract immediately. You can use the drill as a boring bar to rough out a profile or create a chamfer on the way out. This eliminates the need for a separate roughing boring bar, freeing up yet another station in your turret.

The “Chip Evacuation” Factor

If you have ever had to stop a machine because a “bird nest” of stringy chips wrapped around a drill and triggered a load alarm, you know how much downtime chip control causes.

Indexable drills utilize modern chip breakers pressed directly into the carbide insert. These are geometrically designed to snap chips into small “6s” and “9s” that float easily out of the hole with coolant.

Why this improves efficiency:

- Safety: Operators don’t have to reach into the machine with pliers to pull razor-sharp stringy chips off the tool.

- Uptime: The machine runs uninterrupted.

- Surface Finish: Chips don’t drag against the wall of the hole, preserving the finish.

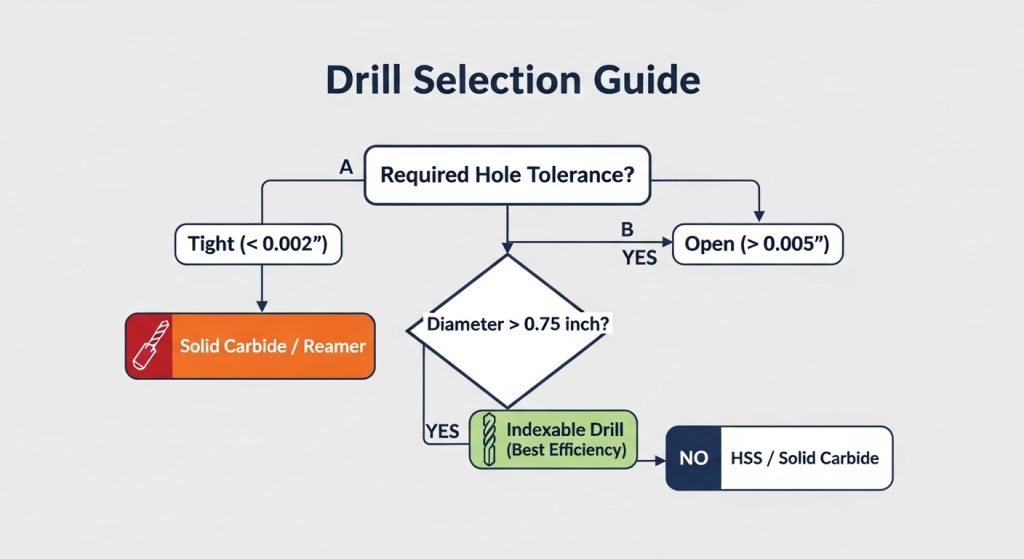

Real-World Limitations: When NOT to Use Them

At Accurate Cut, we believe in being transparent. If we told you indexable drills were perfect for every application, we wouldn’t be doing our job. There are specific scenarios where they are not the right choice.

- High Tolerance Requirements: Indexable drills are not reamers. They are generally “roughing” tools. Expect tolerances around +/- 0.005″ to 0.010″. If you need a press-fit dowel hole, use the indexable drill to remove the bulk of the material, but finish with a boring bar or reamer.

- Rigidity Issues: These drills exert significant radial pressure. If you are running an older, flimsy machine or have a poor workholding setup, an indexable drill might chatter or wander.

- Deep Holes (>5xD): While there are long indexable drills, once you go past 4x or 5x diameter, chip evacuation becomes tricky, and the tool can deflect. Solid carbide is often more stable for very deep, straight holes.

Comparison: Indexable vs. Solid Carbide vs. HSS

To help you visualize where the indexable drill fits in your process, here is a direct comparison. You can also read our detailed breakdown of solid vs. indexable drills for more data.

| Feature | HSS Twist Drill | Solid Carbide Drill | Indexable Drill |

| Speed (SFM) | Low (50-100) | High (200-400+) | High (400-800+) |

| Feed Rates | Low | High | High |

| Peck Cycle? | Yes (Mandatory) | Sometimes | No (Rarely) |

| Initial Cost | Low | High | Medium (High Body, Low Insert) |

| Maintenance | Sharpening (Slow) | Regrinds (Slow) | Index Insert (Instant) |

| Tolerance | Fair | Excellent | Good (Roughing) |

| Versatility | Drilling only | Drilling only | Drilling, Boring, Facing |

FAQ: Common Questions on the Shop Floor

What is the difference between a U-drill and an indexable drill?

In modern machining, the terms are often used interchangeably. Historically, “U-Drill” was a specific product name that became a generic trademark (like Kleenex), referring to a spade-style or early indexable drill. Today, almost all insert-based drills used on CNCs are referred to as indexable drills.

Can I use an indexable drill on a manual lathe?

Technically, yes, but it is risky. Indexable drills require high RPM and consistent feed rates that are hard to maintain manually. More importantly, they require high-pressure coolant to clear chips. Without an enclosure and a coolant pump, you risk welding the tool to the part instantly. We recommend them primarily for CNC use.

Why is my indexable drill screeching?

Screeching usually indicates one of two things: either your surface speed (SFM) is too low, or the center height of the tool is off. Unlike twist drills, indexable drills need to run fast to stabilize. Check that your turret is aligned and bump up the RPM.

Do indexable drills require a pilot hole?

No. In fact, you should not use a pilot hole with most indexable drills. The tool is designed to stabilize itself upon entry. Entering a pre-drilled pilot hole can actually cause the drill to chatter because the stabilizing forces on the outer insert aren’t engaged yet.

How do I calculate the offset for an indexable drill?

Consult your specific tool body’s manual. Generally, you can offset the drill in the X-axis towards the “flat” side of the drill (where the peripheral insert is) to cut a larger diameter. Never offset in the opposite direction, as the drill body will rub against the hole wall.

Conclusion

Efficiency in manufacturing is about removing bottlenecks. If your shop is still relying on HSS drills for holes larger than 3/4″, you are leaving money on the table—not just in cycle time, but in tool changeovers, regrind logistics, and machine uptime.

Indexable drills offer a unique combination of high material removal rates, “zero-change” maintenance, and lathe versatility that other tools simply can’t match. They aren’t just tools; they are production assets.

Ready to optimize your hole-making process?

Review your current cycle times on your highest volume recurring jobs. If you see pecking cycles and frequent drill changes, it’s time to make a change. For more detailed operational tips, be sure to bookmark our indexable drilling guide, or browse Accurate Cut’s selection of high-performance drilling solutions to stop wasting time on chip removal.