Milling Cutter Insert | CNC, & High-Precision Milling Tools

What is a Milling Cutter Insert?

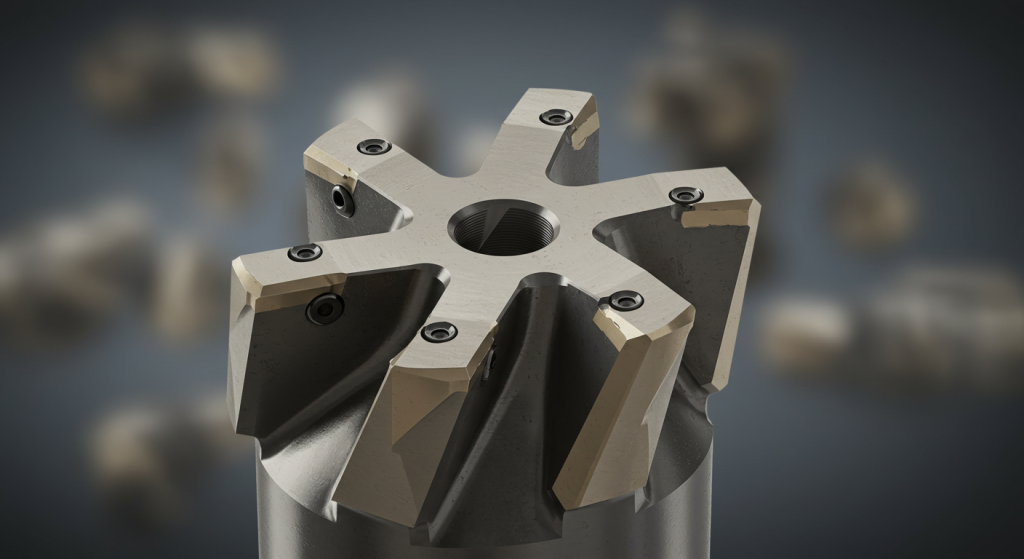

- A cutting face that is a replaceable component of a milling machine or CNC machine. They are cheap and highly versatile compared to solid tools since inserts allow the operator to replace the cutting edges, which become dull, but not the entire tool. These inserts are used during the CNC milling, high-speed machining, and high-precision cutting of metals and provide repeatable performance and high-dimensional accuracy.

- Depending on material, coating, and geometry, milling cutter insert can have numerous functions, some roughing and finishing, others particular to aerospace. They have wide use as milling cutter accessories in industries and precision machining insert systems.

Milling Cutter Insert: Quality, Production, and Precision

Recent industrial machining and CNC processes desire high levels of precision, performance, and longevity. A vital tool that makes this possible is the milling cutter insert, which is an essential accessory in the process of metal cutting, high-precision machining, and high-speed machining. Irrespective of the type of steel, be it steel, aluminum, stainless steel, or aerospace alloys, the milling insert that perfectly fits the machine can yield much better surface finish, lower tool wear, and higher productivity in industrial machining.

Information on Milling Cutter Inserts

The sort and content of milling cutter insert are open to various applications:

- Indexable Milling Insert

Indexable milling inserts are usually designed such that one of the edges can be turned or flipped when they wear out. This facilitates optimum tool life, reduced downtime, and allows a constant cutting performance. They are also prevalent in CNC metal, aluminum, and stainless steel milling machines.

- CNC Milling Insert

CNC milling inserts are computer-controlled machines and are highly designed. With very tight tolerances and advanced coatings, they are very effective even with inserts being machined at high speeds. Good chip removal efficiency, as well as high-quality surface finish, is offered with such inserts.

- Carbide Milling Insert

Carbide inserts are heat-resistant and very hard. They can be cut on hardened steels, aerospace alloys, and stainless steel. To increase wear and life in the carbide milling inserts, they can be plated.

- Coated Milling Insert

Coated tools include titanium nitride (TiN), titanium aluminum nitride (TiAlN), and cermet, which are used to provide extended tool life, lower friction, and allow tools to operate at high speeds without disrupting tool finish. The aerospace, automotive, and heavy industry use coated CNC milling plates.

- Multi-Flute Milling Cutter Insert

Multi-flute inserts offer multiple cutting edges, increasing control of the chips, cutting efficiency, and vibration cutting reduction during milling. They are usually found in industrial metalworking, milling, and high-precision CNC Inset setups.

Material-Specific Milling Cutter Inserts

The thermal resistance and applicability: The stability of a milling cutter insert is determined by its content:

- Carbide Milling Insert: Hard, wear-resistant, best used for CNC metal milling inserts.

- Cermet Milling Insert: Ceramics and metals are sintered to complete at high speed.

- Ceramic Milling Insert: This is used in high-temperature and ultra-hard materials.

- Titanium Coated Milling insert: Reduces heat and wear, extending the lifetime of the tool in high-speed work.

- High-Speed Steel Insert: It is tough and shock-resistant, and can be applied to milling both steel and aluminum.

These material choices have helped manufacturers to maximize cutting speed, tool life, and surface quality finish.

Milling Cutter Inserts

Milling cutter inserts are to fulfill a specific task, and they are as effective and accurate as possible:

- Milling Insert Steel: Cutter is very hard and long-lasting, and can cut alloy and carbon steel.

- Milling Cutter Aluminum: A smooth flute and sharp cutting edge will not create a burr.

- Milling Insert Stainless Steel: Finishes and hard metals help reduce galling and also improve finishes.

- Milling Cutter Aerospace: Aerospace components have been made of titanium and high-strength alloys, and such materials need precision aerospace inserts.

- Milling Insert High-Speed Machining: Cuts with efficiency: Optimized inserts can operate at high rotational speeds without dimensional error.

Key Features and Advantages

- Precision and Accuracy

Milling inserts that are initially of high quality do not lose the high quality of surface finish or dimensional accuracy. Error rates in CNC milling jobs, critical to the aerospace, automotive, and mold-making industries, are eliminated in precision milling inserts.

- Excellent Tool Life and Efficiency

The efficiency of milling inserts is very high, which allows for removing raw materials faster, and less heat is also generated. The flutes and coating are optimized to enhance the efficacy of chip removal, thereby reducing the duration of this chip usage.

- Multi-Edge and Durable

A solid milling cutter that can be indexed or rotated may have more than one cutting edge or flute, with most inserts having much more than one. Multi-flute patterns improve vibration dampening throughout milling and overall tool life.

- Material Versatility

Steel, aluminum, stainless steel, titanium, and aerospace alloys are some of the more varied materials that can be milled by milling inserts. Feed rate and spindle speed optimisation is achieved by inserting material with particular characteristics, and operators realise high productivity.

Coatings and Enhancements

Modern milling inserts may incorporate elaborate coating:

- Titanium Nitride (TiN) Finish: Less friction, higher heat deflection points, and tool life.

- Titanium Aluminum Nitride (TiAlN) Coating: The ideal high-speed steel and aerospace alloy coating.

- Cermet Coating: Enhances the wearing ability in the finishing work.

Such a coating makes the most out of the machine used in the process of industrial machining and makes the operator work long time with high precision CNC insert work.

Conclusion

The milling cutter insert is a veritable, award-winning element of contemporary machining with an ability to provide accuracy, endurance, and performance to a wide range of task uses. Manufacturers can achieve a good surface finish, good tool life, and general productivity in industrial machining with the proper selection of material, coating, and design. High-performance milling cutter inserts do not require more than AccurateCut to discover quality and enduring machining options.