High-Performance Pipe Tap | Precision Thread Cutting Tools

What is a Pipe Tap and How Do They Work?

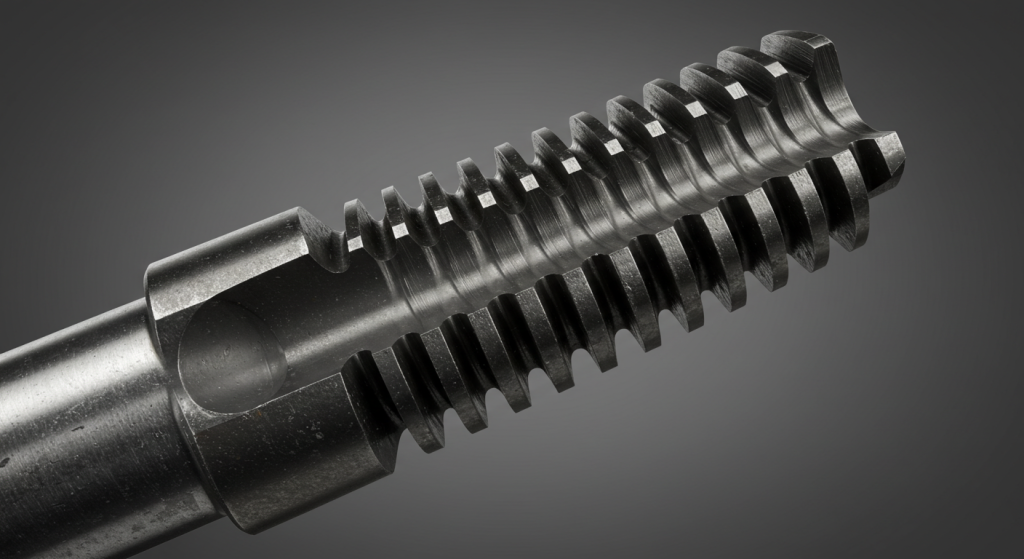

The principle on which a pipe tap is founded is exceedingly simple, yet one which works very successfully: the tap, by means of a certain amount of regulated rotary movement, cuts or forms internal threads, and the fasteners or fittings can then be screwed in with great snugness into the piece of work. The tool has a tapered thread geometry and can be forced slowly through the material, focusing the stress and giving a smooth thread-forming operation. This is achieved by cutting gradually to minimize friction, heat generation, and tool life, and leads to high torque resistance, a smooth thread finish, and correct pitch setting.

To achieve thread finishing without burr, the edges of the tap are ground, and spiral flute or straight flute cross-section designs can be used to create a continuous evacuation of chips and a constant cutting flank. Straight flute taps are favoured where through holes are being drilled and in general-purpose threading, but favoured the spiral flute type where chips are of significance in the whereabouts of the blind holes.

With harder metals, such as stainless, titanium, or alloy steel, a high-speed steel (HSS) tap or a cobalt alloy tap is desirable to enhance cutting and extend the life of the tool. Coated alloys like titanium nitride (TiN) or titanium carbonitride (TiCN) provide a higher degree of wear resistance and corrosion resistance and, as a result, are employed in heavy-duty industrial applications.

Pipe Tap Types and Uses

They are offered in a wide variety of different models, which should be tailored to specific threading needs and material conditions. Two thread systems are most commonly in use, NPT (National Pipe Thread) and BSP (British Standard Pipe). They are compatible with pipes and fittings because of their different thread geometry, taper angle, and pitch combinations.

NPT Tap (National Pipe Thread) – A common North American taper, with a taper of 1:16 to ensure an airtight fit as the thread inserts further into the fitting. It covers a wide range of gas, air, and liquid transportation systems.

BSP Tap (British Standard Pipe) – BSP taps can be of the type known as tapped (BSPT) or parallel (BSPP) and are more commonly used in Europe and Asia. BSPT taps have conical threads, which are designed to close, whereas BSPP tap has straight threads designed to direct fittings accepting a gasket or O-ring.

Straight Pipe Tap – This is a thread type that generates cylindrical threads and is generally appropriate when a threaded connection is needed, but the connection should be centered instead of being filled by force.

Spiral Flute Tap – This tap is applied in blind hole applications and can most easily push the chips out of the hole without clogging, and maintains the threads very precisely.

Plug, Bottoming, and Intermediate Taps – These differ by the number of chamfer threads. Plug taps are general-purpose tools, bottoming taps are bottoming taps, and intermediate taps are intermediate taps.

Technical, Construction, and Performance Characteristics

A modern pipe tap is an art of tool engineering, a combination of optimization of geometry and modern metallurgy to generate wonderful cutting results. The tapered cutting edges and the self-centering design would help in maintaining all alignment correct, and the anti-slip square shanks give good transfer of torque between the tap and the chuck.

These taps are either of high-speed steel (HSS) or cobalt alloy that is heat-treated to a hardness rating (HRC) capable of cutting hard material. Their evacuation chip systems minimize tool clogging, and the flutes are ground to a fine finish to promote smooth cuts and smooth chip removal.

Other Great Technical Advantages are:

- High resistance to high torque and to continuous working.

- Even threading with tight joints that are not leaking.

- Less friction cutting and cutting.

- The potential to tap into a high-speed connection appropriate for the industrial environment.

- Tools with heat and wear-resistant finishes have a long life cycle.

Praise is especially given to the flute pipe tap that is straight, particularly for their reliability in thread accuracy, low dispersion, and high toughness of the cut in terms of machine tapping as well as manual jobs. They can effectively be used in steel pipes, cast iron, and alloy tubing that offer similar outputs in any industrial application.

How Do We Choose a Pipe Tap?

When choosing a tap, you have to consider the following:

- Local compatibility to Thread Standard (NPT, BSP, Metric, or ISO).

- Workpiece material (stainless steel, PVC, cast iron, etc.).

- Cutting strength Tool Material (HSS, cobalt, or carbon steel).

- Coating type (TiN, Ti AlN, or none) based on wear resistance needs.

Application Mode (Machine Tapping or Hand Tapping)

One of the simplest solutions to threading is to use a professional set of taps, such as those available at AccurateCut.com, which can be reliable, precise, and versatile with use.

Checking the cutting edges of your tap and making a regular check on it, proper lubrication of the cutting edges, and not using too much feed pressure can extend the life of your tap. Some tap designs are not usually re-grindable, and as such, appropriate working conditions are of utmost importance. These taps need to be stored in dry and protective cases to prevent corrosion and chipping when not in use.

They also recommend that operators check the accuracy of the tap alignment before a cut- a deflection greater than 0.01mm should be corrected to bring the thread accuracy to zero and prevent a breakage. The following maintenance practices may empower users to maximize their productivity and minimize replacement tool costs.

Conclusion

Not just a threading tool, a pipe tap plays a vital role in defining the right internal threads that define the strength, functionality, and leak-proof integrity of all industrial connections. This is because these tools represent the epitome of precise engineering that has been applied to a broad spectrum of industries worldwide, beginning with plumbing applications to CNC machining. With high-performance threading tools, think of the high quality of tap, thread cutting tools, tap and die kit, and others available at AccurateCut, your machining solution in the industry.