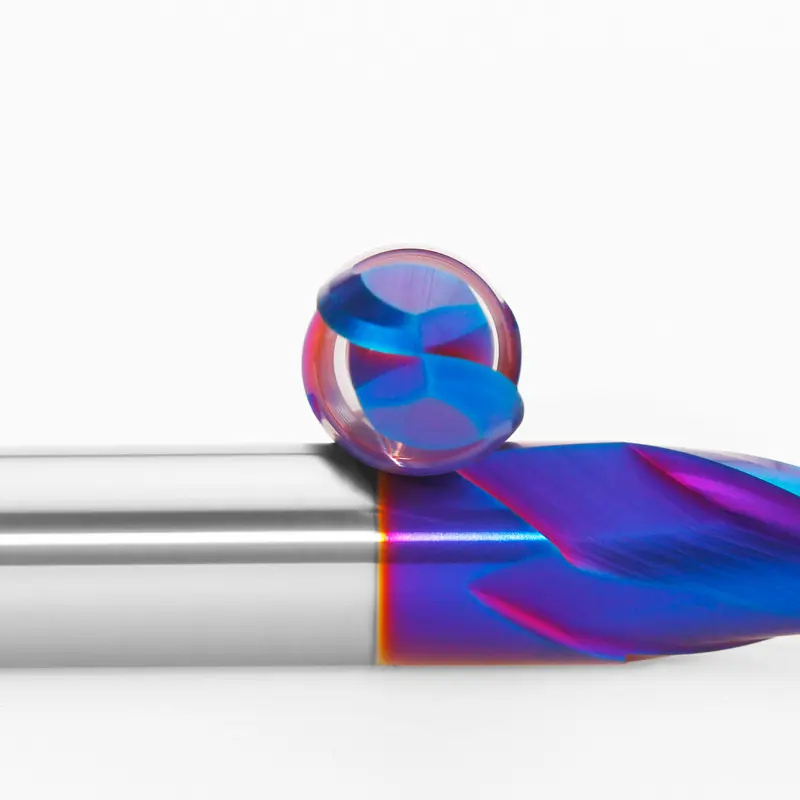

The Ball Nose End Mill offers an outstanding level of accuracy and a bearing surface with a high finishing to the sophisticated curved surfaces and contours in 3D. The design of the rounded tip is to provide continuous contact between surfaces to avoid marking impressions of machining. Moreover, the optimal flute geometry improves the chip evacuation and stability and cutting of chips, even when running on high-speed modes. The good tool will work with hardened steel, mold steel, and alloy steel.

Key Features

-

Nano-Tech Coating: It offers durability to the life of tools with a hardness of 4000HV and a heat of 1200.

-

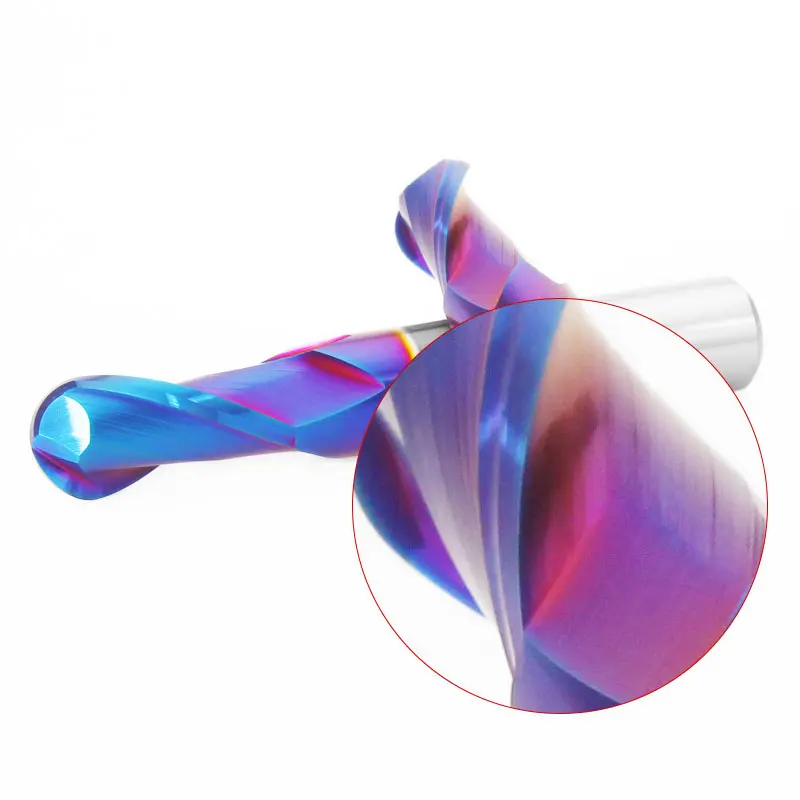

Double-Edge Design: Enhances rigidity, decreases cutting forces, and offers better surface finish.

-

Employee Chip Evacuation (Heavy Capacity Flute Design): Stable chip evacuation when cutting vertical or slots.

-

Bias Operation: This offers even-cutting action of the over-center cutting edge that provides relatively uniform excision on material.

-

Sturdy Construction: Carbide material means the sharpness will last longer, plus it is stable in terms of dimensions.

-

General Purpose: Can be fully used in high-speed finishing of molds and 3D contour milling of dies.

Performance Advantages

-

High Precision: Holds smooth contouring and precise edge profiling of complicated surfaces.

-

Stable Operation: Removes vibration and noise even after prolonged usage in machining.

-

Coats the Excellent Surface Finish: Finishes on a mirror finish with minimum manufacturing afterward, as to post-processing.

-

Long Tool Life: Better heat and wear resistance will minimize the need for tool replacement.

-

Cooling Efficiency: It is most successfully utilized with air or spray cooling and titanium and heat-resistant alloys with liquids, which are insoluble in water.

-

Wide Industry Use: Typical applications are in the aerospace industry, automobile industry, mold making, electrical machines, and lathe machining industries.