Which Supplier Offers Reliable Drill Inserts

In the high-stakes world of industrial manufacturing, consistency is king. A drill insert that performs exceptionally well on Monday but fails catastrophically on Friday is a liability, not an asset. For production managers and engineers, finding a supplier is not just about finding the lowest price—it is about finding a partner that guarantees process security.

At AccurateCut, we understand that our inserts are the heartbeat of your production line. When tooling delivery is delayed or quality fluctuates, spindles stop, and margins vanish. Identifying a reliable supplier requires looking beyond the catalog and evaluating the supply chain, quality control protocols, and technical support infrastructure. This evaluation is a critical step when deciding what to check before buying drill inserts. Here is what defines a truly reliable drill insert supplier.

Criteria 1: Batch-to-Batch Consistency

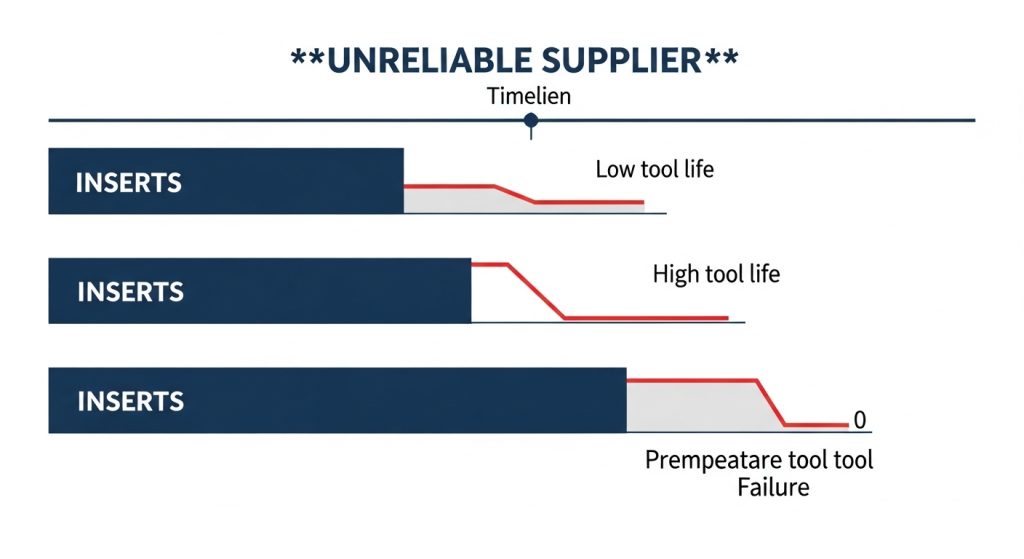

The most common complaint regarding budget tooling suppliers is variability. One box of inserts runs 500 holes; the next box, ordered a month later, chips after 50. This inconsistency often stems from loose controls in the sintering process or substrate mixing.

A reliable supplier guarantees that the grade you qualify today is the exact same grade you receive next year. Strict adherence to ISO tolerance classes and rigid metallurgical quality control ensures that the hardness and toughness of the carbide remain constant. Without this consistency, operators are left guessing why drill inserts break unexpectedly, leading to unplanned downtime.

Criteria 2: Technical Application Support

Many online tooling vendors are simply “box movers”—logistics companies that dropship products without understanding how they work. If you encounter an issue with chip evacuation or surface finish, a box mover cannot help you.

A reliable supplier acts as a technical partner. They should offer accessible engineering support to help you dial in speeds and feeds for specific materials. For example, if you are struggling with edge failure, a true partner can guide you on how to prevent chipping in drill inserts by adjusting your parameters or suggesting a more suitable geometry. At AccurateCut, our technical team is an extension of your engineering department.

Criteria 3: Supply Chain Stability and Stock

The best insert in the world is useless if it is on backorder for six weeks. Supply chain reliability is just as critical as product performance.

What to Look For:

- Domestic Warehousing: Does the supplier stock locally, or are you waiting for international freight?

- Transparent Stock Levels: Can they give you an immediate “Yes” or “No” on availability?

- Blanket Order Capabilities: Will they hold stock specifically for your recurring jobs?

Reliable suppliers invest in buffer stock to insulate their customers from global supply chain disruptions.

Criteria 4: Transparency in Sourcing and Specs

Be wary of suppliers who use vague terminology like “Universal Grade” or refuse to publish detailed data sheets. A trustworthy supplier provides full transparency regarding ISO material classifications, coating types (PVD vs. CVD), and geometry specifications.

This transparency allows you to make data-driven decisions. Knowing the exact specifications of your tooling is essential for predicting wear patterns and extending indexable drill tool life. If a supplier hides the technical details, they are likely hiding quality shortcuts.

The Cost of “Cheap” vs. Reliable

There is a significant difference between “Low Price” and “Low Cost.” A cheap insert that costs $10 but causes a machine crash or produces scrapped parts is infinitely more expensive than a $15 insert that runs reliably for thousands of cycles.

Reliability pays for itself in uptime. When you trust your supplier, you reduce the time spent troubleshooting and inspecting incoming tools. Furthermore, reliable suppliers often provide guidance on the holistic health of your tools, such as the industrial drill maintenance buying guide, ensuring that your drill bodies last as long as possible.

Why AccurateCut is the Industry’s Reliable Partner

AccurateCut was founded to bridge the gap between premium performance and accessible support. We don’t just sell carbide; we provide a stable foundation for your manufacturing processes.

- Direct Quality Control: We monitor every batch to ensure identical performance.

- Expert Support: Our team helps you solve problems, from diagnosing poor hole surface finish to optimizing cycle times.

- Guaranteed Availability: We maintain robust inventory levels to ensure your machines never stop waiting for a package.

Conclusion

Your spindle is only as reliable as your supplier. Stop gambling on “mystery metal” from unverified vendors. By prioritizing batch consistency, technical support, and supply chain transparency, you ensure that your tooling is a predictable, profitable part of your operation.

Contact AccurateCut today to discuss your application and experience the difference of a supplier that puts your production stability first.

Frequently Asked Questions (FAQ)

How can I test a new supplier’s reliability without risking production?

We recommend running a controlled “tool life test” on a non-critical part or during a dedicated setup time. Compare the new inserts against your current baseline, measuring wear patterns and cycle counts. If you encounter issues like clogging, use our guide on how to fix chip packing during drilling to ensure the test is fair and optimized.

Does AccurateCut offer certifications for their inserts?

Yes. AccurateCut can provide data regarding ISO tolerance adherence and coating specifications upon request. We believe in total transparency regarding the metallurgy and geometry of our products.

What happens if an insert doesn’t perform as promised?

A reliable supplier stands behind their product. At AccurateCut, if an insert does not meet performance expectations within the specified parameters, our technical team will work with you to troubleshoot the application or provide a replacement solution.

Why are lead times so variable with some suppliers?

Variable lead times are often a sign of a supplier that relies on “Just-in-Time” dropshipping from overseas manufacturers. Reliable suppliers invest capital in holding their own inventory domestically to buffer against shipping delays.