Step Drill Bit for Stainless Steel –Precision & Professional Use

Expert and Novice Ultimate Guide

This is a hard task, especially with standard bits, since the metal is hard and can resist heat. That is why all professional fabricators, engineers, or home craftsmen turn to the single tool that is very needed, the step drill bit of stainless steel.

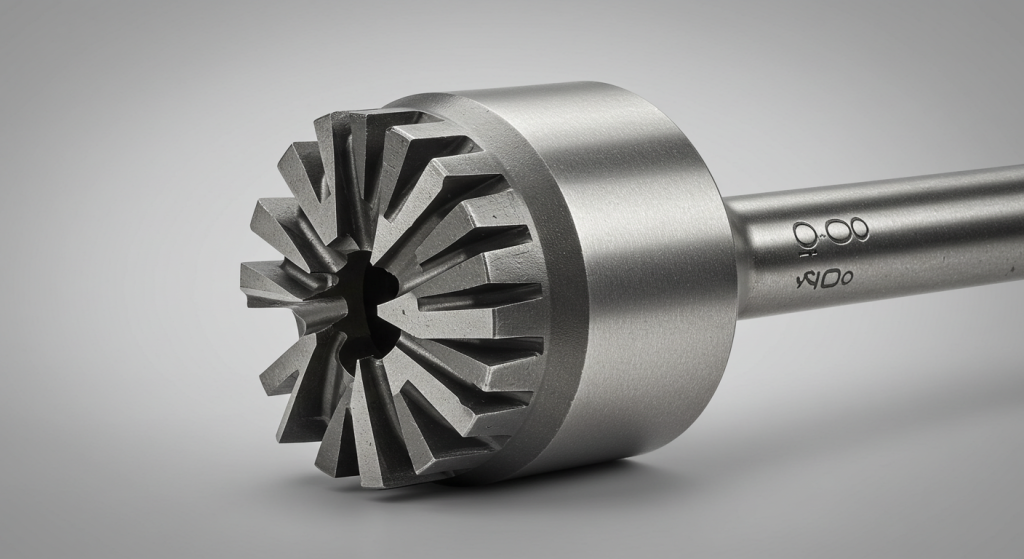

The multi-step cone configuration of this novel bit is capable of drilling various hole sizes without the need to change tools. It would be used on sheet metal, electrical panels, auto body, and stainless steel tubing. The step drill bit for stainless steel qualifies as the most preferable step drill bit to utilize, either when you have to work on a fabrication project or when you have to install kitchen hardware to produce burr-free holes with minimal amount of effort put into it.

Why Choose Step Drill Bits in Stainless Steel?

The hardiness of stainless steel demands a small portion capable of withstanding the great pressure, friction, and temperature. The benefits are constructed on a professional step drill bit on stainless steel as follows:

- Anti-frictional anti-heat coatings such as Titanium Nitride (TiN) are used.

- Alloy alloys containing cobalt are highly hard and provide wear resistance.

- Spiral or double-flute designs do not allow the flute to slice the chip in such a manner.

- Self-centering tips do not require walking and offer precision in drilling.

- Power drills are supplied with anti-slip hex shanks.

Key Performance Features

HSS step drill bit is exceedingly versatile and efficient in regard to creating holes through all kinds of materials. It is composed of high-speed steel (HSS), which endows it with sharp cutting edges, high toughness, and high wear resistance, making it the best in continuous as well as precision drilling.

- The new step design allows the user to drill different sizes of holes with one tool, eliminating the need to change bits frequently and making the working process more efficient. Its flutes are precision-machined, so it ensures clear evacuation of chips and consistent cutting action, low heat production, and superior finishing. This drill bit is incredibly good with both sheet metals and plastics and non-ferrous metals, giving clean burr free edges.

- The tool is made of nano-tech coating, and its hardness is excellent, as high as 4000 HV, and has a thermal stability of up to 1200 °C, or it has long life or high heat capability. The two-sided tool is a bit more rigid, has more wear surface, and less cutting resistance, allowing the tool to drill accurately and efficiently. It possesses high high-capacity junk slot, which facilitates the most optimal chip removal, resulting in an improved machining performance.

- Its design is two flute so that it is easy to discharge the chip and therefore easy to use in vertical feed processing that forms slots and enlarges holes. High precision, high-rigidity tool holders are needed in order to provide maximum performance and increase the life of the tool. Adjust the tool before it is allowed to run and check, and correct deflection unless it travels more than 0.01 mm out of track.

- The shorter the length of the projection, the higher the tool life between the chuck and the projection; the longer the projection, the slower the spindle speed, the slower the feed rate, and the shallower the cutting depth should be. In case of abnormal vibration or noise during drilling, adjust the spindle speed to the feed rate until a steady condition is obtained.

When using steel, spray or air jet cooling is preferred; stainless steel, titanium alloys, and heat-resistant materials are better suited to water-insoluble cutting fluids, so the temperature can best be controlled. Remember that the efficiency of drilling can vary according to the workpiece, machine type, and software settings, and with the conditions stabilized, you can feed at a constant rate of 30-50 percent increments to maximize productivity.

Introduction to a Step Drill Bit on Stainless Steel

A step drill bit for stainless steel, like hard metals like stainless steel, is a technique and care-consuming tool. The following professional tips will be most useful:

- A central punch to indicate where you are drilled to stop slipping.

- Vibration is reduced by clamping the workpiece.

- In a heavier material, a pilot hole should be used.

- The speed (RPM) of the drill should be adjusted between 200 and 500 RPM, depending on the size of the bit.

- Spray with lubricant or cutting oil to reduce heat and increase bit life.

- Cut the drill slowly, letting the bit cut by a slow step.

- Do not press too hard; this will take the shine out of the bit.

These measures are used to ensure the appropriate hole size, a regular cutting motion, and to eliminate overheating.

Applications

In the step drill bits are utilized in numerous industries, and will be required as a result of the versatility of the tool to stainless steel:

- Punching sheet metal for metal fabrication.

- Mounting ductwork and ductwork tools.

- Drilling conduit fittings.

- Part installation and auto body construction.

- Home do-it-yourself metalworking and stainless steel sink projects.

- Connection of pipe and tubing to plumbing or industrial sources.

Such bits are also used in workshops, engineering construction, and in mechanical repair equipment. They can work easily with some of the hardest metals and, as such, are needed in all toolboxes.

Guidelines for Extending Tool Life

To achieve the maximum performance of your step drill bit and its longevity, you should consider the following maintenance procedures:

- And wipe garbage and chips off each time you use them, or they will grow dull.

- Light oil is used as a storage agent to prevent rust and corrosion.

- Do not drill at high RPMs, which causes overheating.

- Apply lubricants or coolants, and cutting becomes a lot easier.

- Lap edges often, and sharpen as required with a precision grinder.

Proper maintenance ensures that your drilling tools are in proper shape and condition so that you do not need to change them after a relatively short time.

Conclusion

The stainless steel step drill is not an instrument, but a renaissance in metal fabrication. It is an ideal tool with its multi-step cone shape, wear-resistant coating, and self-centered drilling capability to drill stainless steel sheets, tubing, and hardware installations. To view the top-rated step drill bits, industrial drill accessories, and metal cutting solutions, log on to AccurateCut.com, which is also your trusted partner in precision engineering and fabrication solutions.