What Are Drill Inserts and Why They Matter

If you have ever thrown away an entire drill bit just because the cutting lips chipped or the corner broke down, you know the feeling of watching money hit the scrap bin. In high-volume manufacturing, treating expensive tooling as a consumable is a fast track to bleeding profit.

I’ve walked into countless machine shops where operators are nursing along dull High-Speed Steel (HSS) bits or burning through expensive solid carbide drills on roughing jobs. The solution often isn’t a “better” drill bit, but a different system entirely.

This is where drill inserts (often called indexable drills) change the game.

At Accurate Cut, we focus on precision and efficiency. In this guide, we’ll break down exactly what drill inserts are, why they are the backbone of modern production drilling, and how to decide if your shop needs to make the switch.

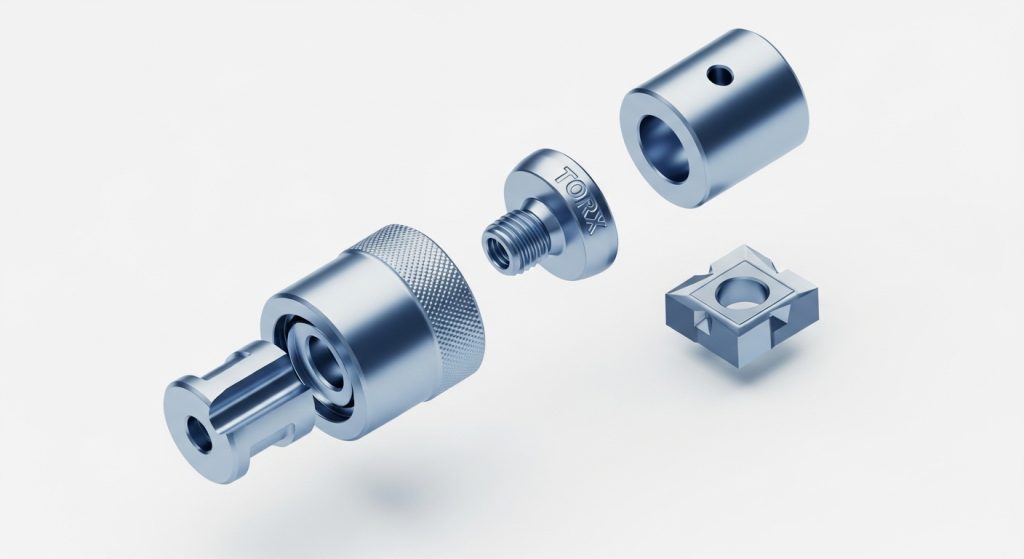

What Is a Drill Insert System? (The Anatomy)

A drill insert system (or indexable drill) consists of a reusable steel drill body and replaceable carbide cutting tips (“inserts”). Instead of sharpening the tool when it dulls, you simply rotate or replace the carbide insert, keeping the main body in the machine.

Think of it like a safety razor. You don’t throw away the handle when the blade gets dull; you swap the blade.

An indexable drill is typically engineered with two distinct cutting inserts:

- The Central Insert: Cuts the center of the hole. Because the surface speed at the absolute center of a drill is zero, this insert takes a beating and usually wears out differently than the outer one.

- The Peripheral (Outer) Insert: Cuts the diameter. This insert travels at the highest surface speed and defines the hole size and finish.

The Mechanics of the Cut

Unlike a solid twist drill that relies on a chisel edge, indexable drills rely on the balance of forces between these two inserts.

In my experience, the magic happens in the geometry. The inserts are positioned so that the radial forces cancel each other out. If they didn’t, the drill would wander immediately. This allows indexable drills to remove material at incredible rates—often 3x to 4x faster than HSS—without the need for a pilot hole.

The Economics: Why Drill Inserts Matter

If you ask a purchasing manager why they like inserts, they’ll tell you it’s about price. If you ask a machinist, they’ll tell you it’s about speed. Both are right.

Here is the breakdown of why drill inserts matter for your bottom line:

Reduced Cost Per Hole (CPH)

The initial investment in a high-quality indexable drill body might give you sticker shock compared to a twist drill. However, the Cost Per Hole is where you win.

- A solid carbide drill might cost $150. Once it’s dead (after a few regrinds), you buy another $150 tool.

- An insert might cost $12. The drill body lasts for hundreds, sometimes thousands, of holes.

Minimized Machine Downtime

This is the hidden killer in production. When a solid tool dulls, the operator has to stop the machine, remove the tool holder, find a new drill, measure the tool length offset (TLO), and update the CNC controller.

With drill inserts, you can often change the insert inside the machine without removing the holder. You index the screw, torque it down, and hit the green button. You’ve just turned a 15-minute changeover into a 60-second pause.

Inventory Versatility

One of the biggest advantages I see in job shops is versatility. Let’s say you are drilling 4140 steel in the morning and 6061 aluminum in the afternoon. With solid tools, you need two completely different drill bits.

With an indexable system, you keep the same drill body and simply swap the grade of the insert. You put in a tough, coated grade for the steel and a sharp, polished grade for the aluminum.

Comparison: Drill Inserts vs. Solid Carbide vs. HSS

Not sure which tool is right for your current job? Here is how they stack up.

| Feature | High-Speed Steel (HSS) | Solid Carbide | Indexable Drill Inserts |

| Initial Cost | Low | High | Medium (Body) / Low (Inserts) |

| Feed Rates | Slow | High | Very High |

| Hole Tolerance | IT11 – IT12 | IT8 – IT9 (High Precision) | IT10 – IT11 (Production) |

| Maintenance | Resharpening required | Regrinding required | Index/Replace (Zero maintenance) |

| Ideal Diameter | Any size | < 12mm (0.5″) | > 12mm (0.5″) |

| Depth capability | Very Deep | Up to 8x-12x Diameter | Typically 2x – 5x Diameter |

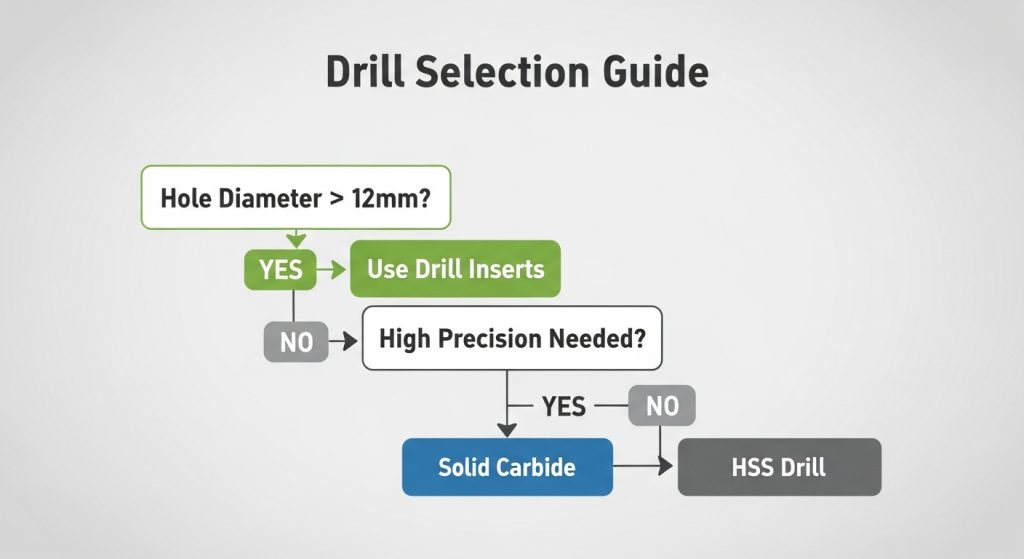

The Bottom Line: Use Solid Carbide when you need extreme precision or small holes (under 12mm). Use Drill Inserts for holes larger than 12mm where speed and volume are the priority.

Understanding Insert Geometries and Grades

You can’t just grab any insert and expect it to work. The “science” of the cut comes down to the ISO codes and coatings.

The Shapes: WCMX vs. SPMG

You will often see codes like WCMX or SPMG on boxes.

- Square types (SPMG): These are robust. They offer four cutting edges (you can rotate the insert four times before throwing it away), making them very economical.

- Trigon types (WCMX): These usually offer three edges but tend to have better centering capabilities and lower cutting forces.

Coatings and Substrates

Standard carbide wears out fast in heat. That’s why manufacturers apply specialized PVD or CVD coatings.

- TiN (Titanium Nitride): The classic gold color. Good for general purpose.

- TiAlN (Titanium Aluminum Nitride): Often violet or grey. This is essential for harder steels or stainless because it thrives in high heat.

Practical Application: Best Practices for Success

I’ve seen many shops buy their first indexable drill, run it like an HSS drill, and blow it up immediately. Don’t be that shop.

Stability is Non-Negotiable

Indexable drills exert tremendous radial pressure. If your workpiece isn’t clamped down tight, or if your spindle has play, the drill will chatter. Chatter kills carbide instantly. Ensure your setup is rigid.

Coolant Pressure is Critical

If you are drilling 3x or 4x deep, you need to get the chips out. Unlike twist drills, indexable drills usually have straight flutes, not helical ones. They rely on coolant-through pressure (blast of coolant coming out the tip of the drill) to flush chips up and out.

Rule of Thumb: You generally need at least 150 PSI for effective chip evacuation in deeper holes. If you only have flood coolant, be very careful with hole depth.

Don’t Peck

Old school machinists love to “peck drill” (drill, retract, drill, retract) to break chips. Do not do this with indexable drills. They are designed to run continuously. Pecking causes the carbide to chip as it re-enters the cut. Trust the feed rate to break the chip.

Common Mistakes When Switching to Inserts

Here are the top errors competitors make (and how you can avoid them):

- Running too slow: Carbide needs heat to plasticize the metal slightly. If you run an indexable drill at HSS speeds (low RPM), you will actually chip the edge faster. Push the RPMs up.

- Ignoring the Body Wear: The steel body doesn’t last forever. Over time, the pocket where the insert sits will wash out from chip erosion. If the pocket is loose, the insert moves, and your tool breaks.

- Misalignment on Lathes: If you are using these on a CNC lathe, the turret must be perfectly aligned with the spindle. Even a 0.005″ misalignment can cause the center insert to snap because it’s being forced to cut sideways.

Conclusion

Drill inserts represent a shift from “tooling as a possession” to “tooling as a system.” While they aren’t the answer for every single hole—specifically micro-drilling or high-precision aerospace bores—they are the undisputed king of material removal rates for standard production.

By switching to indexable drilling, you gain control over your inventory, reduce your machine downtime, and ultimately, lower the cost of every part that leaves your shop.

If you are looking to optimize your production line, it might be time to stop grinding old bits and start indexing new ones.

Ready to improve your shop’s efficiency? Explore Accurate Cut’s range of high-performance drilling systems today.

Frequently Asked Questions

Can I regrind drill inserts?

No. Drill inserts are designed to be “indexable” (rotated to a fresh edge) and then discarded/recycled once all edges are used. Regrinding removes the specialized coating and alters the geometry, which would ruin the tool’s performance.

What is the minimum diameter for indexable drills?

Typically, the smallest practical diameter for indexable drills is around 12mm (approx. 0.5 inches). Below this size, the screws and inserts become too small and fragile to handle the cutting forces, so solid carbide is the superior choice.

Why is my indexable drill making a tapered hole?

Tapering is usually caused by tool deflection. This happens if the drill is too long for the diameter (e.g., a 5xD drill used for a shallow hole) or if the feed rate is too high, causing the drill body to bend slightly under load.

Can I use drill inserts on a manual lathe?

Yes, but with caution. Indexable drills require high horsepower and rigidity. Manual lathes often lack the necessary RPM and the rigid holding capability of a CNC turret, which can lead to chatter or tool breakage.

How many times can I index a drill insert?

This depends on the shape of the insert. WCMX (trigon) inserts usually have 3 usable edges. SPMG (square) inserts have 4 usable edges. Always check the manufacturer’s specification for your specific ISO code.