Which Industries Use Indexable Drilling Tools

Every shop manager knows the feeling. You’ve got a half-million-dollar machining center sitting idle because the operator is digging through a drawer looking for a specific twist drill, or worse, re-touching off a tool because the regrind length changed. In the manufacturing world, hole-making is often the biggest bottleneck in production, yet it’s frequently the last place people look for efficiency gains.

If you are still relying heavily on High-Speed Steel (HSS) or comparing solid carbide vs indexable drills for holes larger than half an inch, you are likely leaving money on the table.

At Accurate Cut, we’ve seen firsthand how switching to indexable drilling technology transforms production floors. It’s not just about drilling a hole faster; it’s about predictability, inventory management, and the “Cost-Per-Hole” metric. While solid carbide reigns supreme for micro-precision, indexable drills have become the workhorse for industries that demand high material removal rates (MRR) and minimal downtime.

Here is a deep dive into the industries that rely on indexable drilling tools and why they made the switch.

What Are Indexable Drilling Tools?

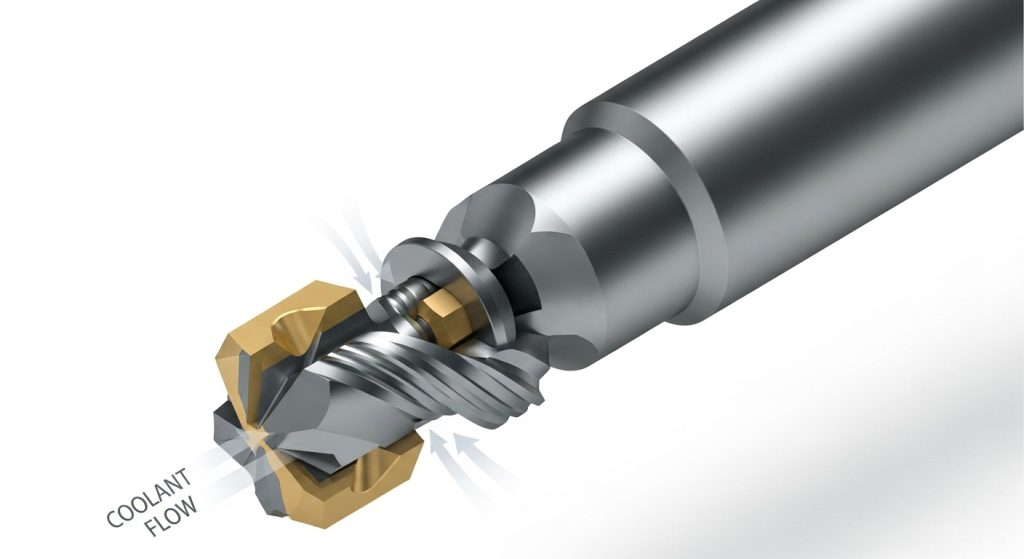

Before we look at the specific sectors, let’s clarify the technology. Unlike a solid drill, an indexable drill consists of a steel body that holds replaceable carbide inserts. Typically, there is an inner insert (central) and an outer insert (peripheral).

The primary advantage here is versatility and speed. These tools are designed to run at much higher surface footages (SFM) than HSS and can handle significantly higher feed rates. When an edge wears out, you simply index (rotate) or replace the insert. You don’t have to remove the tool from the holder, and you don’t have to re-measure the tool length offset.

Quick Spec Overview:

- Diameter Range: Typically efficient from 0.500″ (12.7mm) up to 3.00″ (76mm) or larger.

- Coolant: Almost exclusively used with through-spindle coolant to evacuate chips rapidly.

- Depth: Standard ratios are 2xD, 3xD, 4xD, and 5xD.

The Automotive Industry: High-Volume Efficiency

The automotive sector is arguably the largest consumer of indexable drilling technology. In an industry where cycle times are measured in seconds and production runs in the hundreds of thousands, reliability is everything.

Why They Use It

Automotive manufacturers rely on transfer lines and high-efficiency CNC centers to machine engine blocks, transmission cases, crank shafts, and suspension components. The material is often abrasive cast iron or gummy aluminum alloys.

The “Uptime” Advantage:

In my experience walking production lines, the killer isn’t just the cutting speed—it’s the tool change time. If a solid carbide drill chips in a high-volume cell, the machine stops. The operator has to pull the tool, replace it, and qualify the new length.

With indexable tools from Accurate Cut, if an insert chips, the operator enters the cell, swaps the screw and insert in under 60 seconds, and hits “Cycle Start.” The tool length never changed.

Specific Applications

- Crankshaft Oil Holes: Drilling deep, cross-holes where chip evacuation is critical.

- Steering Knuckles: large diameter clearance holes in cast iron.

- Differential Housings: Roughing out large bores before a finishing pass.

The Aerospace Sector: Precision on Exotic Materials

Aerospace machining is a different beast entirely. Here, volume is lower, but the part value is incredibly high. You might be working on a landing gear component forged from Titanium or a structural bracket made of Inconel.

Managing Thermal Load

Exotic heat-resistant superalloys (HRSA) generate immense heat during machining. Solid carbide drills can suffer from thermal cracking in these environments, leading to catastrophic failure inside the part.

Aerospace engineers prefer indexable drills because they can select specific insert grades for the material. They might use a tough, PVD-coated grade for the inner insert to handle the low surface speed at the center, and a harder, CVD-coated grade for the outer insert to withstand the heat at the periphery.

Risk Mitigation

Imagine drilling a hole into a $20,000 titanium forging. If a solid drill breaks, extracting it might scrap the part. Indexable drills are generally more forgiving. If an insert fractures, the steel body often survives, and the part can be salvaged. At Accurate Cut, we advise aerospace clients to view indexable tooling as an insurance policy against scrap.

Common Aerospace Materials Drilled:

- Titanium 6Al-4V

- Inconel 718

- 17-4 PH Stainless Steel

Oil, Gas, and Energy: Large Diameter & Deep Holes

When you walk into a shop machining parts for the energy sector—whether it’s oil field valves or wind turbine hubs—you see massive components. The holes required here are rarely under 1 inch. They are often 2, 3, or 4 inches in diameter.

The Spade Drill vs. Indexable Debate

Traditionally, this industry used Spade Drills (blade drills) for big holes. While spade drills are cost-effective for very deep holes, they are slow.

The energy sector has aggressively moved toward indexable drills for hole depths up to 5xD because of the Material Removal Rate (MRR). An indexable drill can often run at 3x to 4x the penetration rate of a spade drill. When you are drilling 50 bolt holes in a massive heat exchanger flange, that difference cuts hours off the job.

Applications

- Fluid Ends: High-pressure blocks used in fracking.

- Flanges: Bolt circles on massive pipeline connections.

- Turbine Components: Large mounting holes for wind energy units.

Heavy Equipment & Job Shops

This is the sector where versatility is king. Manufacturers of earth-moving equipment (like excavators and bulldozers) and general job shops value indexable drills for a unique reason: Lathe Functionality.

The “Offset” Secret

Here is a trick experienced machinists love: On a CNC lathe, if you are using an indexable drill, you can offset the X-axis slightly to change the hole size.

For example, if you have a 1.00″ indexable drill, but you need a 1.015″ hole for clearance, you don’t need to buy a special drill size or add a boring bar operation. You can simply program the lathe to drill the hole, and then bore it out with the same tool by shifting the X-axis. This capability eliminates an entire tool change and frees up a station on the turret.

Why Job Shops Choose Accurate Cut Indexable Tools:

- Reduced Inventory: One drill body covers a range of diameters (by adjusting offset on lathes) and materials (by changing inserts).

- Roughing Capability: They are excellent for rapid material removal before a boring bar finishes the hole to tight tolerance.

- Durability: They handle interrupted cuts (like drilling through cross-holes) much better than solid carbide, which tends to chip on the exit.

Comparative Analysis: When to Use Indexable vs. Solid Carbide

We often get asked, “Should I throw away all my twist drills?” The answer is no. Indexable drills are a powerhouse, but they aren’t for every application.

Here is the breakdown of when to use which:

| Feature | Solid Carbide / HSS | Indexable Drill |

| Hole Diameter | Best for < 0.500″ (12mm) | Best for > 0.625″ (16mm) |

| Tolerance | High Precision (H7 – H9) | Looser Tolerance (+/- 0.005″ – 0.010″) |

| Surface Finish | Excellent | Good (Usually requires finishing) |

| Speed (MRR) | Moderate | Extremely High |

| Setup Time | Slow (Regrinds change length) | Fast (Inserts allow static length) |

| Stability | Good for older/lighter machines | Requires rigid machine & high pressure coolant |

The Bottom Line: Use solid carbide when you need a precise, finished hole in one shot, especially under 1/2 inch. Use indexable drills when you need to make a lot of chips fast, hole sizes are larger, or you are roughing out a bore.

Key Benefits of Switching to Indexable Systems

If your shop fits into one of the industries above, the ROI on switching to indexable tooling is usually realized within the first few jobs.

- Lower Inventory Costs: Instead of stocking expensive solid carbide drills in every size (which sit in a drawer collecting dust), you stock a few drill bodies and boxes of inserts. The capital tied up in tooling drops significantly.

- Consistent Power Consumption: As a solid drill wears, the power required to push it grows exponentially. Indexable inserts cut freely, and because they are changed frequently, spindle load remains consistent, protecting your machine.

- No Regrinding Logistics: You eliminate the “bin of dull drills” waiting to go to the sharpener. This streamlines shop management.

Conclusion

From the high-speed transfer lines of the automotive industry to the heavy-duty demands of the energy sector, indexable drilling tools have become the standard for efficient hole-making. They offer a unique combination of speed, versatility, and cost control that solid tooling simply cannot match in larger diameters.

However, success relies on implementation. These tools require adequate coolant pressure and a rigid setup to perform.

If you are looking to reduce your cycle times and lower your cost-per-hole, it might be time to consult our comprehensive indexable drilling guide or audit your drilling strategy.

Ready to optimize your production? Explore the high-performance drilling solutions at Accurate Cut. Our team can help you match the right body and insert geometry to your specific material and machine capabilities.

Frequently Asked Questions

What is the minimum diameter for indexable drills?

While technology is improving, the practical minimum for indexable drills is usually around 0.375″ (9.5mm) to 0.500″ (12.7mm). Below this size, the screws required to hold the inserts become too small and fragile for industrial environments. For holes smaller than this, solid carbide remains the superior choice.

Can indexable drills be used on a manual lathe?

Technically, yes, but it is not recommended. Indexable drills require high RPM and high coolant pressure to evacuate chips and keep the inserts cool. Manual lathes often lack the safety enclosures (to protect from flying hot chips) and the coolant pressure needed. Using them manually often leads to premature insert failure.

What is the difference between a spade drill and an indexable drill?

A spade drill uses a single, wide blade that spans the entire diameter. It is excellent for very deep holes and older, less rigid machines. An indexable drill uses two or more discrete carbide inserts. The indexable drill is significantly faster (higher feed rates) and produces better chips, but it requires a more rigid, modern CNC machine.

Are indexable drills suitable for finishing?

Indexable drills are primarily “roughing” tools. While they leave a decent finish, they will usually leave visual retraction marks and the tolerance is typically around +/- 0.005″. If your print calls for a tight tolerance hole (like a dowel pin hole), you should use the indexable drill to rough it, and follow up with a boring bar or reamer.

Why does my indexable drill squeal?

Squealing or “chatter” usually indicates instability. This can be caused by:

- Low Feed Rate: Indexable drills need to be pushed hard to stabilize the cut.

- Workholding: The part is vibrating.

- Tool Overhang: The drill is sticking out too far.

- Coolant: Insufficient coolant is causing chips to jam.