How to Fix Off-Center Holes in Drilling: The Expert Guide

Nothing ruins a shift faster than scrapping a complex part because of off-center holes. You spend hours programming and setting up, only to find the drill walked. Now the bolt pattern doesn’t match, or the wall thickness is compromised.

I have seen this happen on million-dollar aerospace parts and simple brackets alike. The frustration is universal.

The good news is that hole deviation is rarely a mystery. It is a symptom of a mechanical or procedural failure. By isolating the variables—setup, tool geometry, and machine alignment—you can drill true every time.

This guide covers exactly why drills walk and how to fix it. We will look at spotting, toolholders, and machine alignment. We will stop the drift and save your scrap rate.

Why Are My Drilled Holes Drifting Off-Center?

Drilled holes drift primarily due to poor initial contact (walking), machine misalignment, or excessive tool runout. If the drill tip does not penetrate the material perfectly on center, or if the drill body deflects due to lack of rigidity, the hole will inevitably wander off the intended axis.

When a drill touches the part, it seeks the path of least resistance. If the surface is uneven or the drill point is dull, it “skates.” Once the tip starts off-center, the entire hole follows that bad path.

The Physics of “The Walk”

Drills, especially long twist drills, are not perfectly rigid. They act like stiff springs.

- Entry deflection: This is the most common cause. The tip hits, slides 0.005″ to the side, and bites in.

- Internal stress: As the drill deepens, uneven flute pressure pushes it further sideways.

To prevent this foundationally, you must ensure your machine foundation is solid. Before blaming the tool, review our CNC Setup Optimization Guide to ensure your workholding isn’t allowing micro-movements.

How Does Spot Drilling Prevent Hole Deviation?

Spot drilling creates a precise centering cone that guides the subsequent drill, preventing the tip from walking across the material surface. By using a spot drill with an angle equal to or slightly larger than the final drill, you force the cutting edges to engage evenly and immediately.

I often see operators skip the spot drill to save cycle time. This is false economy. Saving 3 seconds on a spot drill often costs you the part tolerance.

The “Golden Rule” of Angles

- Twist Drills (118°/135°): Use a 140° spot drill. This ensures the tip of the secondary drill cuts first, centering itself.

- Carbide Drills: Many solid carbide drills are self-centering and do not require spotting. In fact, spotting can sometimes chip them. Always check manufacturer data.

If you are running a mill, the approach is straightforward. However, if you are unsure about the specifics of tool selection for your machine type, read our guide on Indexable Drills in Machining Centers.

Is Lathe Turret Misalignment Causing the Issue?

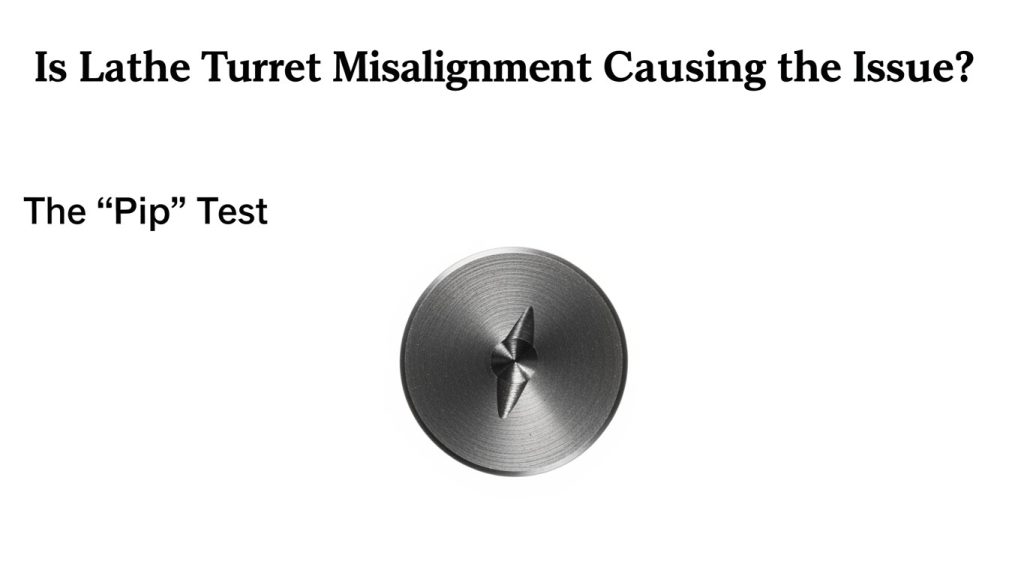

On a lathe, if the turret pocket is not perfectly concentric with the spindle centerline, the drill will be pushed off-center immediately upon contact. This misalignment creates a “pip” or nub at the bottom of the hole and forces the drill body to flex, resulting in an oversized, tapered, or eccentric hole.

I once diagnosed a machine making oval holes. The operator blamed the insert. The real culprit? A crash two months prior had knocked the turret 0.010″ off center.

The “Pip” Test

Drill a blind hole and look at the bottom.

- Clean bottom: You are on center.

- Small numb (Pip): You are slightly off.

- Large Pip: You are significantly off-center.

Correcting this requires mechanical realignment of the turret. For a step-by-step breakdown of lathe-specific drilling nuances, refer to How to Use Indexable Drills on a Lathe.

Can Toolholder Runout Create Off-Center Holes?

Yes, Total Indicated Runout (T.I.R.) in the toolholder causes the drill to rotate in an orbital path rather than a perfect circle, effectively cutting a hole larger than the drill and offset from the center. Even a runout of 0.0005″ at the spindle nose can translate to 0.003″ at the drill tip.

Cheap collets are the number one killer of hole position accuracy. If the collet is worn or dirty, it introduces error before the cut even starts.

Choosing the Right Holder

- ER Collets: Good for general work, but prone to runout if not cleaned perfectly.

- Hydraulic Chucks: The gold standard. They clamp concentrically and dampen vibration.

- Shrink Fit: Extremely accurate, but requires heating units.

If you are fighting position tolerance, swap your holder. See our comparison of the Best Toolholders for Indexable Drills to find the most rigid option for your setup.

How Do Cutting Forces and Chatter Affect Hole Position?

Excessive vibration (chatter) causes the drill to bounce and deflect within the hole, leading to poor surface finish and positional drift. When a drill chatters, it is not cutting consistently; it is hammering the material, which inevitably pushes the tool off its intended centerline.

You can hear an off-center hole being made. That high-pitched scream is the sound of the drill deflecting.

Stabilizing the Cut

- Shorten the tool: Use the shortest drill possible.

- Check the speed: You might be in a harmonic vibration zone.

- Increase Feed: Paradoxically, pushing harder often stabilizes the drill.

If your drill is screaming, it is walking. You must solve the vibration to solve the position. Learn how to silence the cut in our article: How to Avoid Chatter During Indexable Drilling.

Does Chip Packing Push the Drill Off Course?

When chips fail to evacuate, they pack into the flutes and act as a wedge between the drill and the hole wall, forcing the drill off-center. This “hydraulic packing” creates immense pressure that will either break the drill or push it sideways, ruining positional accuracy.

This is common in deep hole drilling (over 3xD). If the chips don’t come out, the drill wanders.

The Solution: Flow and Pecking

- Coolant Pressure: You need high pressure to blast chips up the flutes.

- Peck Drilling: If you lack through-spindle coolant, use a peck cycle to break and lift chips.

Don’t let chips dictate your hole location. Master chip management by reading Improve Chip Evacuation in CNC Drilling.

Troubleshooting Guide: Why Is My Drill Walking?

Use this quick-reference table to diagnose your specific issue on the shop floor.

| Symptom | Likely Cause | Solution |

| Drill skates at entry | Uneven surface / No spot | Mill a flat or use a spot drill. |

| Hole is oval/oversized | Toolholder Runout | Clean collet or switch to Hydraulic Chuck. |

| Pip at bottom of hole | Lathe Center Misalignment | Re-align turret to spindle center. |

| Drill wanders deep in part | Chip Packing | Increase coolant pressure or add peck. |

| Loud squealing sound | Chatter / Harmonics | Adjust RPM and Feed to stabilize. |

Summary

Fixing off-center holes requires a systematic approach. You must stop the drill from walking at the start, hold it true during rotation, and clear the path for it to cut.

Start by checking your runout. If the tool spins true, check your machine alignment. Finally, ensure your process—spotting and chip control—is sound.

Precision is not luck. It is control.

Frequently Asked Questions

1. Why do my drilled holes end up off-center? Holes usually end up off-center because the drill “walked” upon entry due to an uneven surface or lack of a spot drill. Other causes include toolholder runout, machine misalignment (especially on lathes), or chip packing forcing the drill sideways.

2. How do I stop my drill from walking? To stop a drill from walking, create a pilot divot using a spot drill or center drill. Ensure the spot drill angle is equal to or greater than the drill point angle. Alternatively, mill a small flat surface on the part before drilling.

3. Does tool runout affect hole position? Yes, tool runout directly affects hole position. If the toolholder does not spin perfectly concentric to the spindle, the drill will cut an orbit rather than a circle, resulting in oversized and off-center holes.

4. How do I check if my lathe turret is aligned? Drill a shallow blind hole and inspect the bottom. If there is a noticeable “pip” or nub at the very center, your turret is misaligned. The size of the pip correlates to the severity of the misalignment.

5. Can chatter cause a hole to be off-center? Yes, chatter indicates instability and deflection. If a drill is vibrating, it is bouncing against the hole walls. This deflection causes the drill to wander from its intended path, ruining the positional tolerance.

6. Is a spot drill always necessary? Not always. Short, rigid carbide drills are often self-centering and can drill directly into solid material. However, for long twist drills (over 3xD) or when entering uneven surfaces, a spot drill is highly recommended to guarantee accuracy.